97

6 - Maintenance

Lubrication

General Info

Always store lubricants clean, dry and cool - preferably at a constant temperature - to avoid contamination from dirt and

condensed water. Keep oil filling jugs, hoppers and grease guns clean, and clean the lubricating points thoroughly before

lubricating. Avoid skin contact with oil products for longer periods.

Always follow the quality and quantity recommendations. If no quantity recommended, feed the lubricator until new grease

becomes visible.

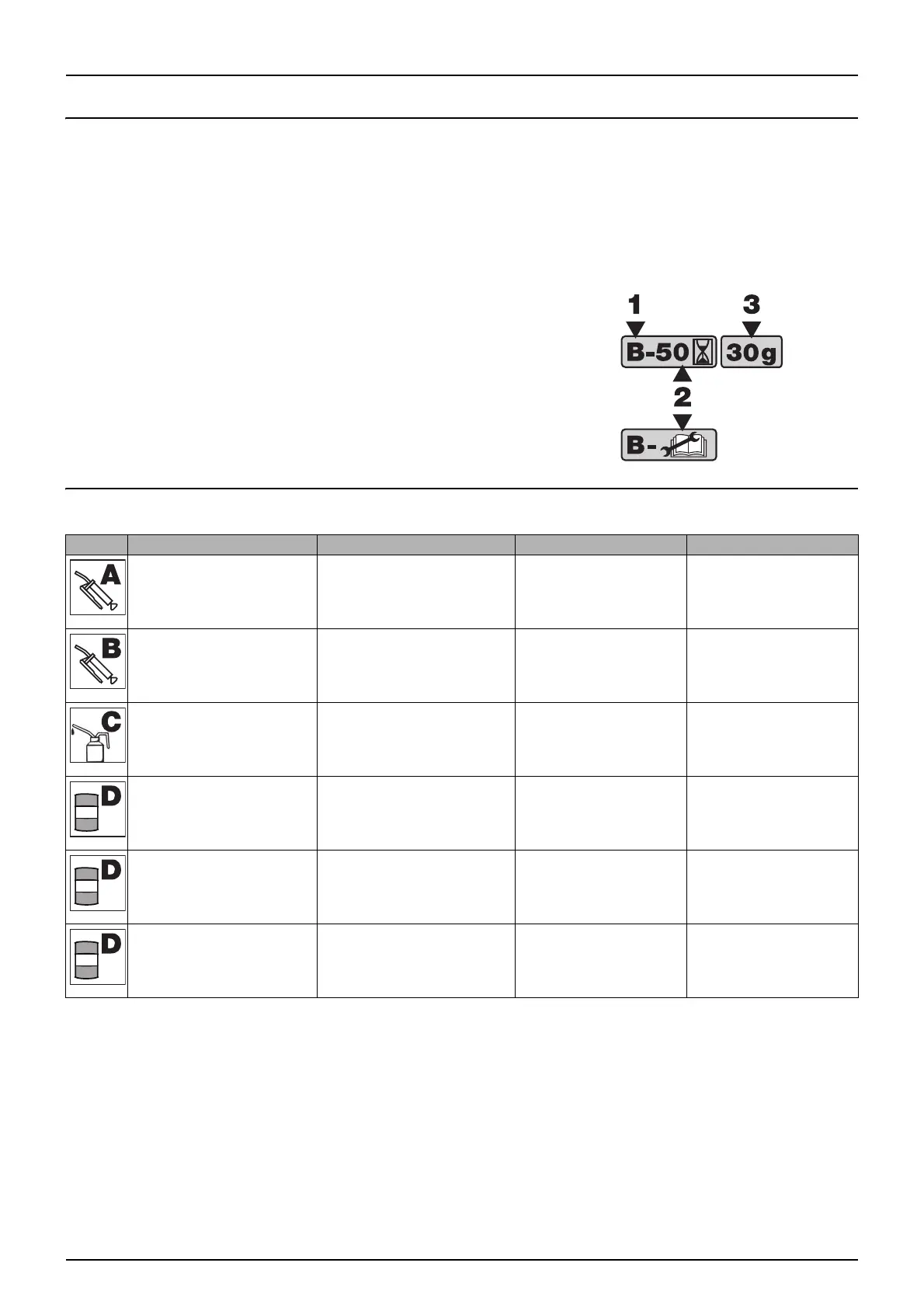

Pictograms in Lubrication & Oiling Plans

1. Lubricant to be used (see “Suitable lubricants” below).

2. Recommended intervals. Shown in hours or with a symbol for

occasional maintenance.

3. Quantity to use. Only shown if specifying a quantity.

μ

ATTENTION! Recommended is lubrication of the entire machine,

if cleaning the sprayer with a high-pressure washer.

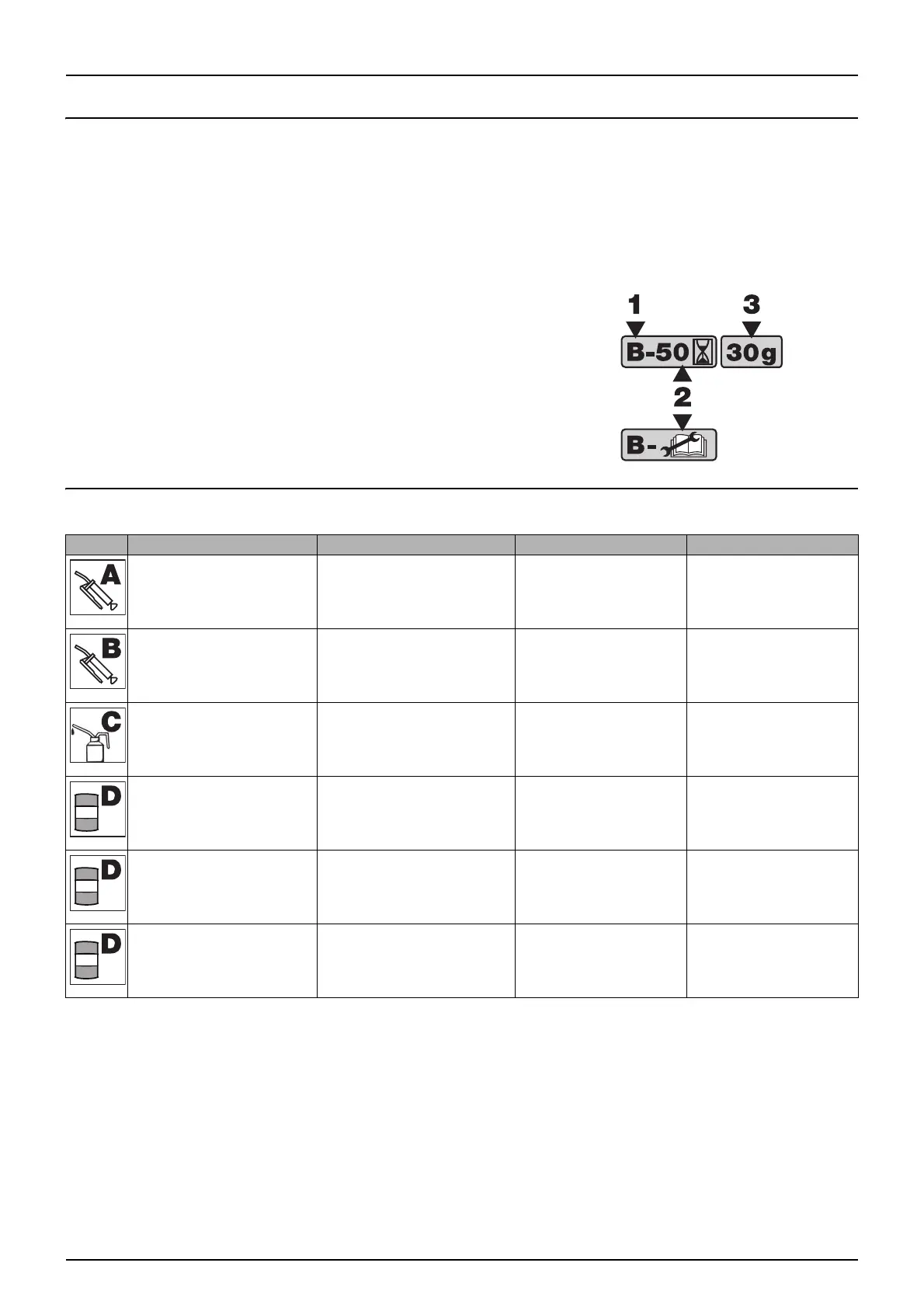

Suitable Lubricants

What to Lubricate? Lubricant Type Factory Use Suitable Alternatives

BALL BEARINGS and PUMP Lithium based grease

Consistency NLGI grade 2

Viscosity (@40°C) > 460 cSt

SHELL Gadus S3 V550L 1

Hardi pump grease cartridge

(400g): Item no. 28164600

MOBIL grease XHP 462

TOTAL Multis Complex SHD 460

SLIDE BEARINGS Lithium based grease

Consistency NLGI grade 1/2

Viscosity (@40°C) > 200 cSt

MOBIL XHP 222 SHELL Gadus S3 V220C 2

TOTAL Multis Complex SHD 220

OIL LUBRICATION POINTS Engine or transmission oil

Viscosity 20W-50 or 80W-90

OK Tractor UTTO GL 4 80W SHELL Spirax S4 TXM

CASTROL ACT EVO 4T

MOBIL Mobilube HD 80W/90

GLIDE SHOES IN BOOM CENTRE Stearic or a non-greasy type of wax

or

engine or transmission oil

BOLTS Anti-corrosive wax PAVA PV 700 TECTYL 506 WD

VALVES and SEALS (O-RINGS) NSF 51, NSF 61 silicone compound ROCOL SAPPHIRE Aqua-Sil DOW CORNING MOLYKOTE 111

Compound

Loading...

Loading...