6 - Maintenance

106

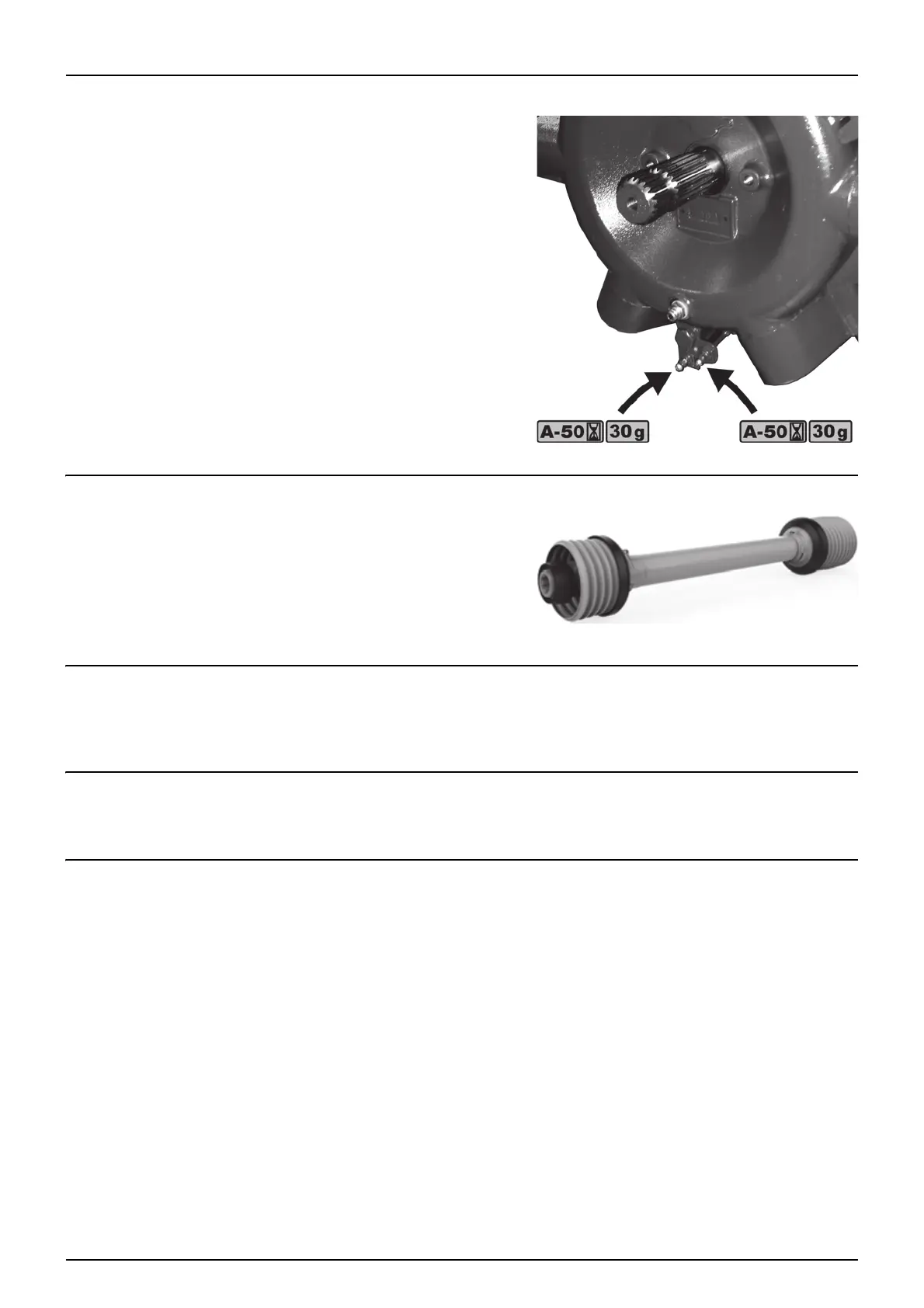

50 Hours Service - Greasing the Pump

Grease is necessary every 50 hours with 30 grams of grease into each

lubrication point, when operating the pump.

μ

ATTENTION! In order to avoid excessive wear, it is important to

use a recommended lubricant! See the section “Recommended

Lubricants” for more information.

μ

ATTENTION! When greasing the pump MUST be stopped!

50 Hours Service - Transmission Shaft (PTO)

1. Check function and condition of the transmission shaft protection

guard. Replace any damaged parts.

2. Lubrication. See “Lubrication and Oiling Plan - PTO” on page 140.

100 Hours Service - Re-tightening the Spray Boom

Due to several movements of the spray boom from driving in the field with an unfolded boom, you must re-tighten all

bolted connections on the boom centre and boom wings.

250 Hours Service - Hydraulic Circuit

Check the hydraulic circuit for leaks. Repair if needed.

250 Hours Service - Hoses and Tubes

Check all hoses and tubes for possible damage and proper attachment. Replace damaged hoses or tubes.

In general, always replace a hose or tube if:

• It is leaking.

• Reinforcement material inside the hose is visible due to cracks in the outer layers.

Loading...

Loading...