MACHINE OPERATIONS AND CONTROLS

METHOD FOR REPLACING AND INVERTING BUCKET

• When pins are knocked in with a hammer, pieces of metal may fly and cause serious injury.

When performing this operation, always wear protective eyeglasses, hard hat, gloves, and other

protective equipment.

• Place the removed bucket in a stable condition.

• The pin is hit with a strong force to remove, so the pin may fly out and injure people in the area

around the machine. Make sure that there is no one in the area around the machine before starting

the work.

• When pulling out the pins, do not stand behind the bucket. In addition, take extreme care not to put

your foot under the bucket since the bucket may fall and cause serious injury.

• When removing or inserting pins, be extremely careful not to get your fingers caught.

• Never insert your fingers into the pin holes when aligning the holes.

Stop the machine on a firm and flat surface and do the work. When performing joint work, appoint a leader and

follow that person's instructions and signals.

METHOD FOR CHANGING BUCKET

1.

Lower the bucket to the flat ground.

REMARK

When removing the pins, place the bucket so that it is in light contact with the ground.

If the bucket is lowered strongly to the ground, the resistance will be increased and it will be difficult to re-

move the pins.

NOTICE

After removing the pins, make sure that mud or sand does not get on them. Dust seals are fitted at both

ends of the bushings, be careful not to damage them.

2.

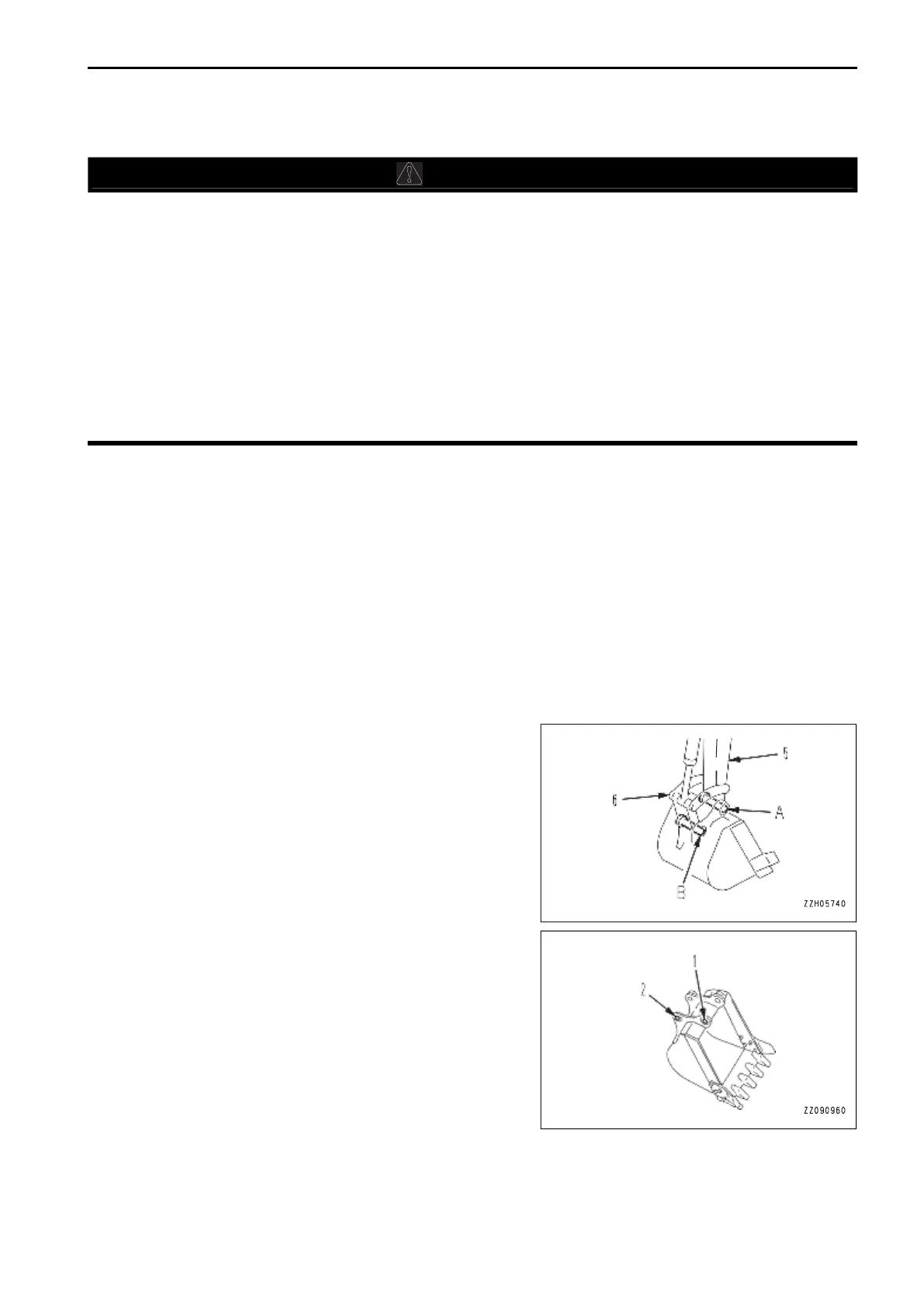

Remove the double nut of stopper bolt at arm pin (A) and

link pin (B), then pull out the bolts.

3.

Pull out arm pin (A) and link pin (B), then remove the buck-

et.

4.

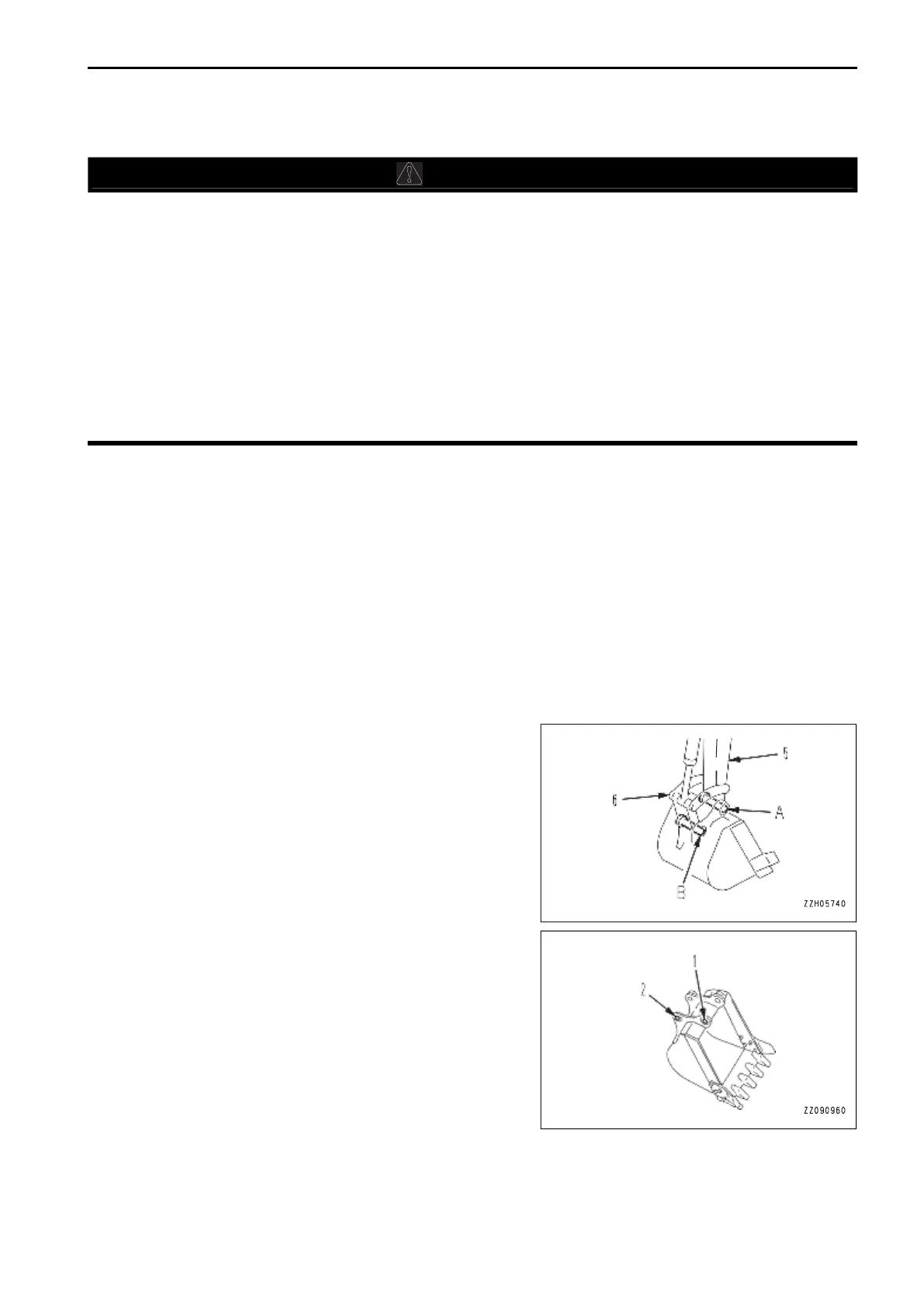

Align arm (5) with hole (1) of the replacement bucket.

5.

Align link (6) with hole (2) of the replacement bucket.

6.

Apply grease to pins (A) and (B) and insert them into

holes (1) and (2) of the bucket.

Loading...

Loading...