METHOD FOR CHECKING LOOSENESS AND TIGHTENING ROAD LINER SHOE

BOLTS

NOTICE

If the machine is used with road liner shoe bolts loose, they will break. Tighten any loose shoe bolts

immediately.

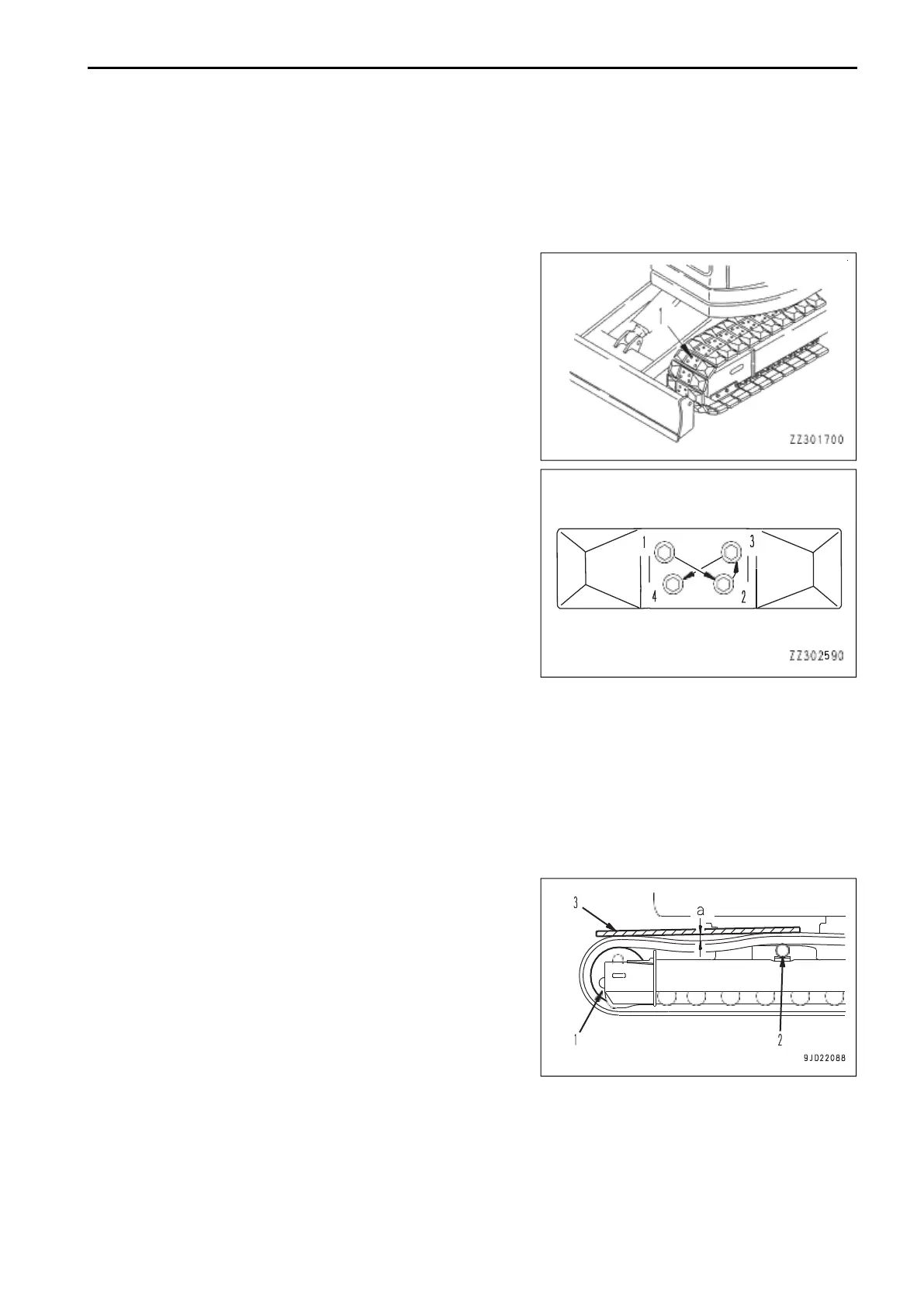

1.

Check for looseness of the road liner shoe bolt (1).

2.

If any looseness of the bolt is found, tighten it in order

shown in the figure.

Tightening torque: 176.4 to 215.6 Nm

3.

Check that the nut and shoe are in close contact with the

link contact surface.

METHOD FOR CHECKING AND ADJUSTING TRACK TENSION

The wearing of the pins and bushings in the undercarriage depends on the working condition and type of soil.

Check the track tension occasionally and keep it in the standard range.

For performing the inspection and adjustment of the track shoes, park the machine on the level and solid

ground.

METHOD FOR CHECKING TRACK TENSION

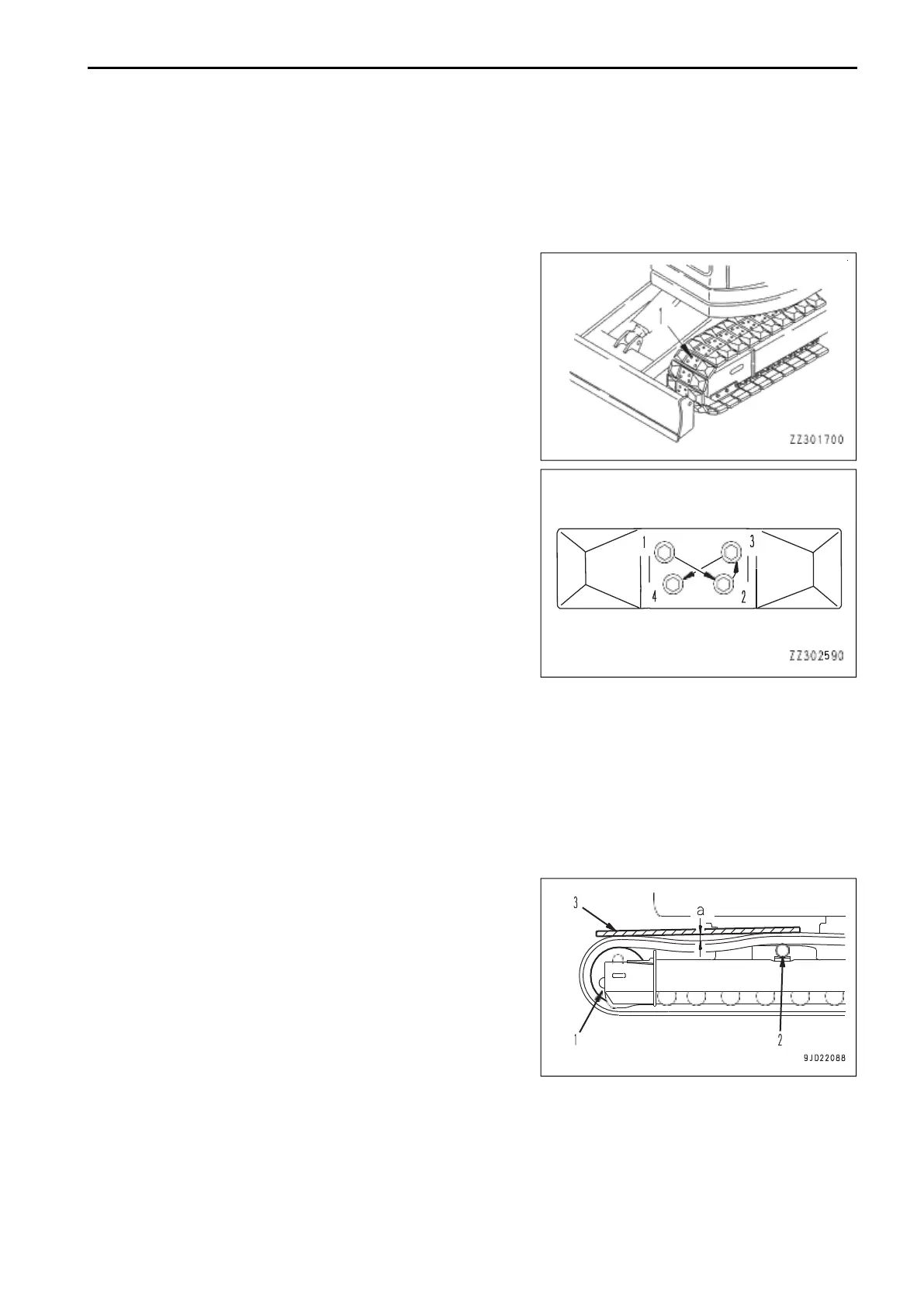

1.

Run the engine at low idle, then move the machine forward for a distance equal to the track length on

ground, and slowly stop the machine.

2.

Place straight wooden square bar (3) which reaches from

idler (1) to carrier roller (2) on the track.

3.

Measure the maximum deflection (a) between the bottom

surface of the wooden bar and top surface of the track

shoes.

Standard deflection

Deflection (a) should be 10 to 30 mm.

If the deflection is out of the standard range, adjust it into the standard range.

METHOD FOR INCREASING TRACK TENSION

Prepare a grease pump.

Loading...

Loading...