12.

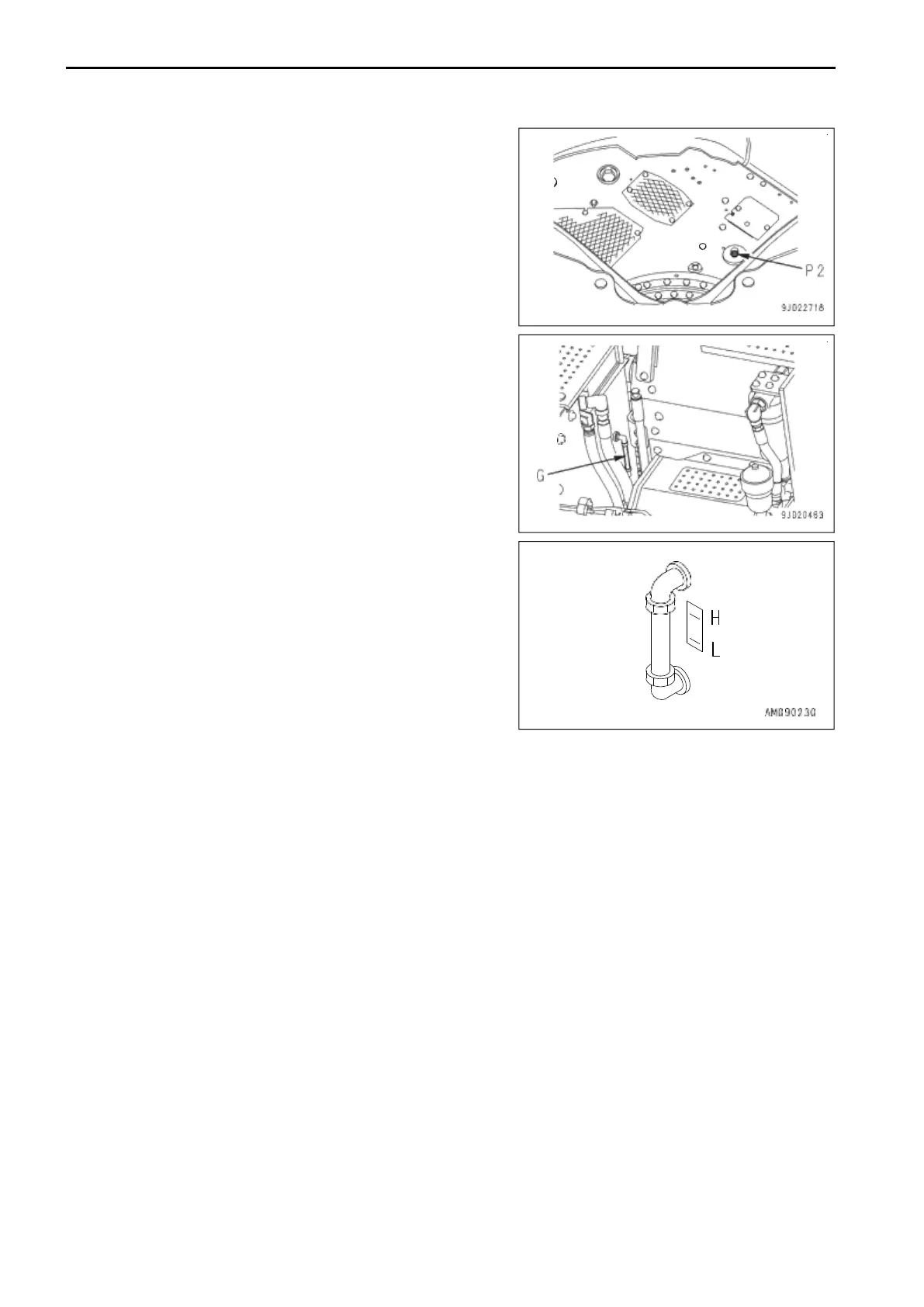

Remove the drain plug (P2), and drain the oil.

• When removing the drain plug (P2), be careful not to

get oil on yourself. Check the installed O-ring for dam-

age. Replace the O-ring with a new one if necessary.

13.

After draining the oil, tighten the drain plug (P2).

Tightening torque: 58.8 to 78.4 Nm

14.

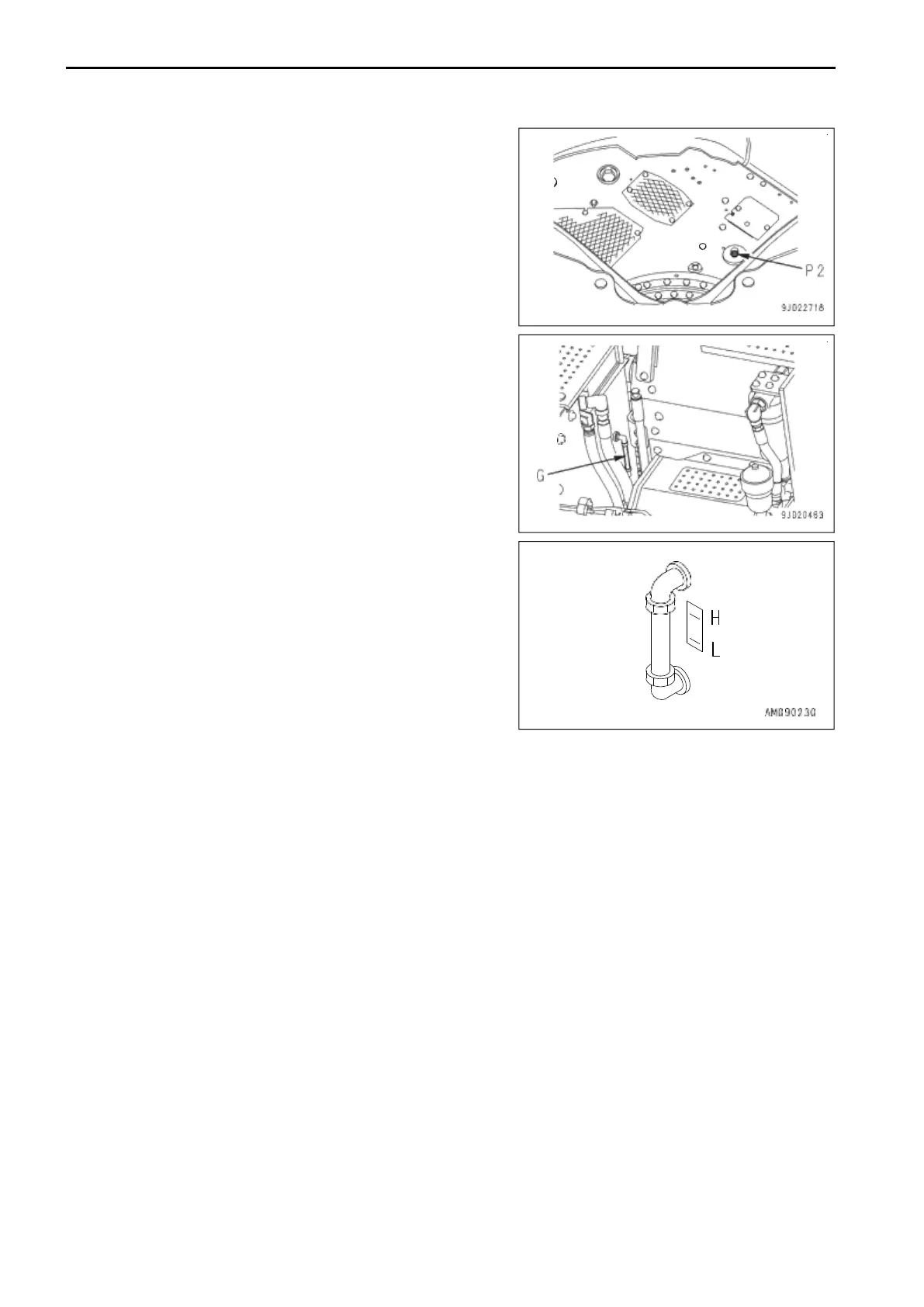

Add the refill capacity of oil through oil filler port (F).

15.

Check that the oil level is between H and L lines on sight

gauge (G).

For applicable oils, see “METHOD FOR USING FUEL,

COOLANT AND LUBRICANTS ACCORDING TO AMBI-

ENT TEMPERATURE (7-6)”.

For the check of oil level and the installation procedure of

the oil filler cap, see “METHOD FOR CHECKING OIL LEV-

EL IN HYDRAULIC TANK, ADDING OIL (3-132)”.

16.

Bleed air from the hydraulic circuit.

For the air bleeding procedure of hydraulic circuit, see

“METHOD FOR BLEEDING AIR FROM HYDRAULIC CIR-

CUIT (4-37)”.

17.

Install the hydraulic tank top cover (2).

EVERY 8000 HOURS MAINTENANCE

Maintenance for every 100, 250, 500, 1000, 2000 and 4000 hours service should be performed at the same

time.

METHOD FOR REPLACING ENGINE HIGH-PRESSURE PIPING CLAMP

Special techniques and tools are required for this work.

Ask your Komatsu distributor for replacement of the engine high-pressure piping.

METHOD FOR REPLACING FUEL SPRAY PREVENTION CAP

Ask your Komatsu distributor for replacement of the fuel spray prevention caps.

EVERY 9000 HOURS MAINTENANCE

Maintenance for every 100, 250, 500, 1000 and 4500 hours service should be performed at the same time.

METHOD FOR REPLACING DEF HOSE

Ask your Komatsu distributor for replacement of the DEF hose.

END OF SERVICE LIFE

• For safe dismantling of the machine at the end of service life, please contact your Komatsu distributor.

Loading...

Loading...