1.

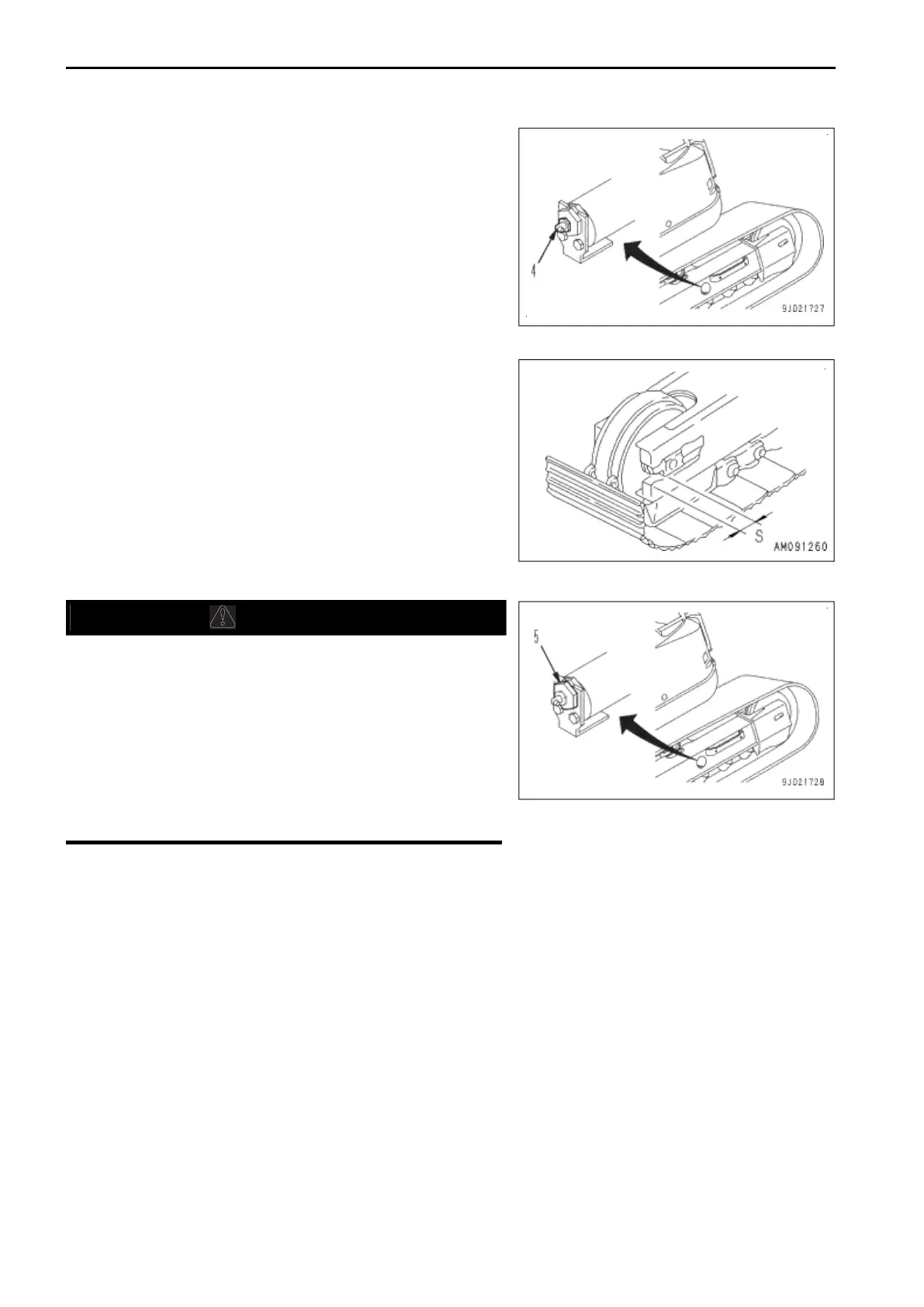

Pump in grease through grease fitting (4) by using a

grease pump.

2.

To check if the tension is correct, run the engine at low

idle, move the machine slowly forward (by an amount

equal to the length of track on ground), then stop the ma-

chine.

3.

Check the track tension again, and if the tension is not correct, adjust it again.

Continue to pump in grease until S becomes 0 mm. If the

tension is still loose, the pins and bushings are excessively

worn, so they must be either turned 180° or replaced.

Ask your Komatsu distributor for repair.

METHOD FOR DECREASING TRACK TENSION

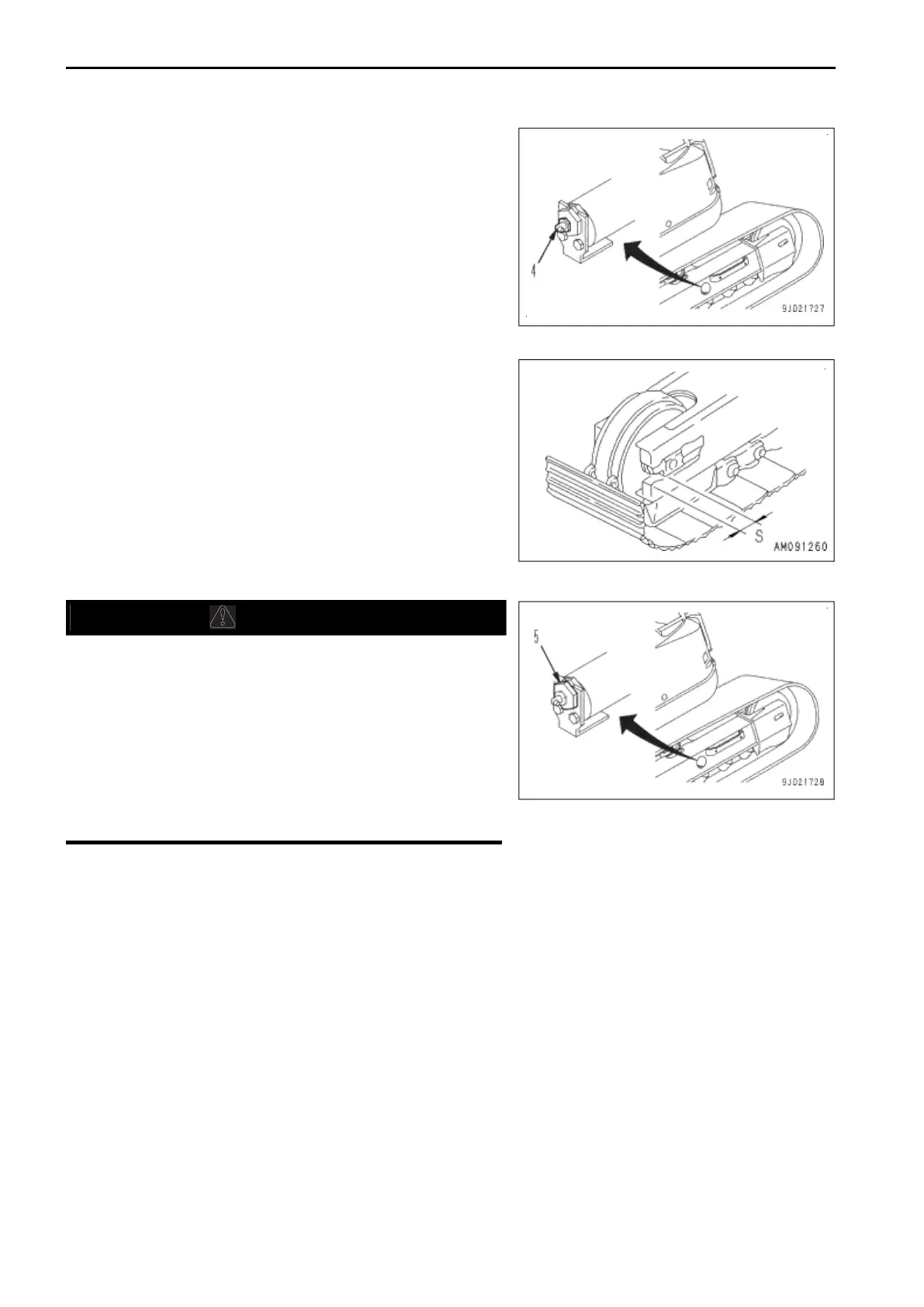

• Never loosen plug (5) more than 1 turn.

If plug (1) is loosened more than 5 turn, there is a dan-

ger of plug (1) flying out under the high internal pres-

sure of the grease.

Never loosen any part other than plug (5). Never put

your face in the mounting direction of plug (5).

• It is extremely dangerous to release the grease by any

method other than the procedure shown here.

If track tension is not relieved by this procedure, con-

tact your Komatsu distributor for repairs.

1.

Loosen plug (5) gradually to release the grease.

When loosening plug (5), turn it a maximum of 1 turn.

2.

If the grease does not come out smoothly, move the machine forward and backward a short distance.

3.

Tighten plug (5).

4.

To check if the tension is correct, run the engine at low idle, move the machine slowly forward (by an

amount equal to the length of track on ground), then stop the machine.

5.

Check the track tension again, and if the tension is not correct, adjust it again.

METHOD FOR CHECKING ROAD LINER

(Road liner specification)

If the road liners are in the following condition, they must be replaced. Ask your Komatsu distributor for replace-

ment.

Loading...

Loading...