MAINTENANCE SCHEDULE TABLE

METHOD FOR REPLACING DEF TANK BREATHER ELEMENT ................................................................... 4-62

METHOD FOR CHECKING FAN BELT TENSION AND REPLACING FAN BELT ........................................ 4-63

EVERY 2000 HOURS MAINTENANCE........................................................................................................................ 4-63

METHOD FOR CLEANING HYDRAULIC TANK STRAINER ............................................................................ 4-64

METHOD FOR CHECKING AND RELEASING NITROGEN GAS CHARGE PRESSURE IN ACCUMULA-

TOR (FOR CONTROL CIRCUIT) ...................................................................................................................... 4-65

METHOD FOR CHECKING ALTERNATOR AND STARTING MOTOR .......................................................... 4-68

METHOD FOR CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE............................................ 4-68

METHOD FOR REPLACING KCCV FILTER ELEMENT ................................................................................... 4-68

METHOD FOR REPLACING DEF FILTER .......................................................................................................... 4-71

EVERY 4000 HOURS MAINTENANCE........................................................................................................................ 4-73

REPLACE DEFINED LIFE PARTS ....................................................................................................................... 4-73

METHOD FOR CHECKING WATER PUMP ........................................................................................................ 4-74

METHOD FOR REPLACING ACCUMULATOR (FOR CONTROL CIRCUIT) ................................................. 4-74

METHOD FOR CHECKING FOR LOOSENESS OF ENGINE HIGH-PRESSURE PIPING CLAMP, HARD-

ENING OF RUBBER ........................................................................................................................................... 4-75

METHOD FOR CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER .

............................................................................................................................................................ 4-75

EVERY 4500 HOURS MAINTENANCE........................................................................................................................ 4-76

REPLACE KCCV HOSE ......................................................................................................................................... 4-76

METHOD FOR CLEANING DEF TANK ................................................................................................................ 4-76

EVERY 5000 HOURS MAINTENANCE........................................................................................................................ 4-76

METHOD FOR CHANGING OIL IN HYDRAULIC TANK ................................................................................... 4-76

EVERY 8000 HOURS MAINTENANCE........................................................................................................................ 4-78

METHOD FOR REPLACING ENGINE HIGH-PRESSURE PIPING CLAMP .................................................. 4-78

METHOD FOR REPLACING FUEL SPRAY PREVENTION CAP .................................................................... 4-78

EVERY 9000 HOURS MAINTENANCE........................................................................................................................ 4-78

METHOD FOR REPLACING DEF HOSE ............................................................................................................ 4-78

END OF SERVICE LIFE ......................................................................................................................................... 4-78

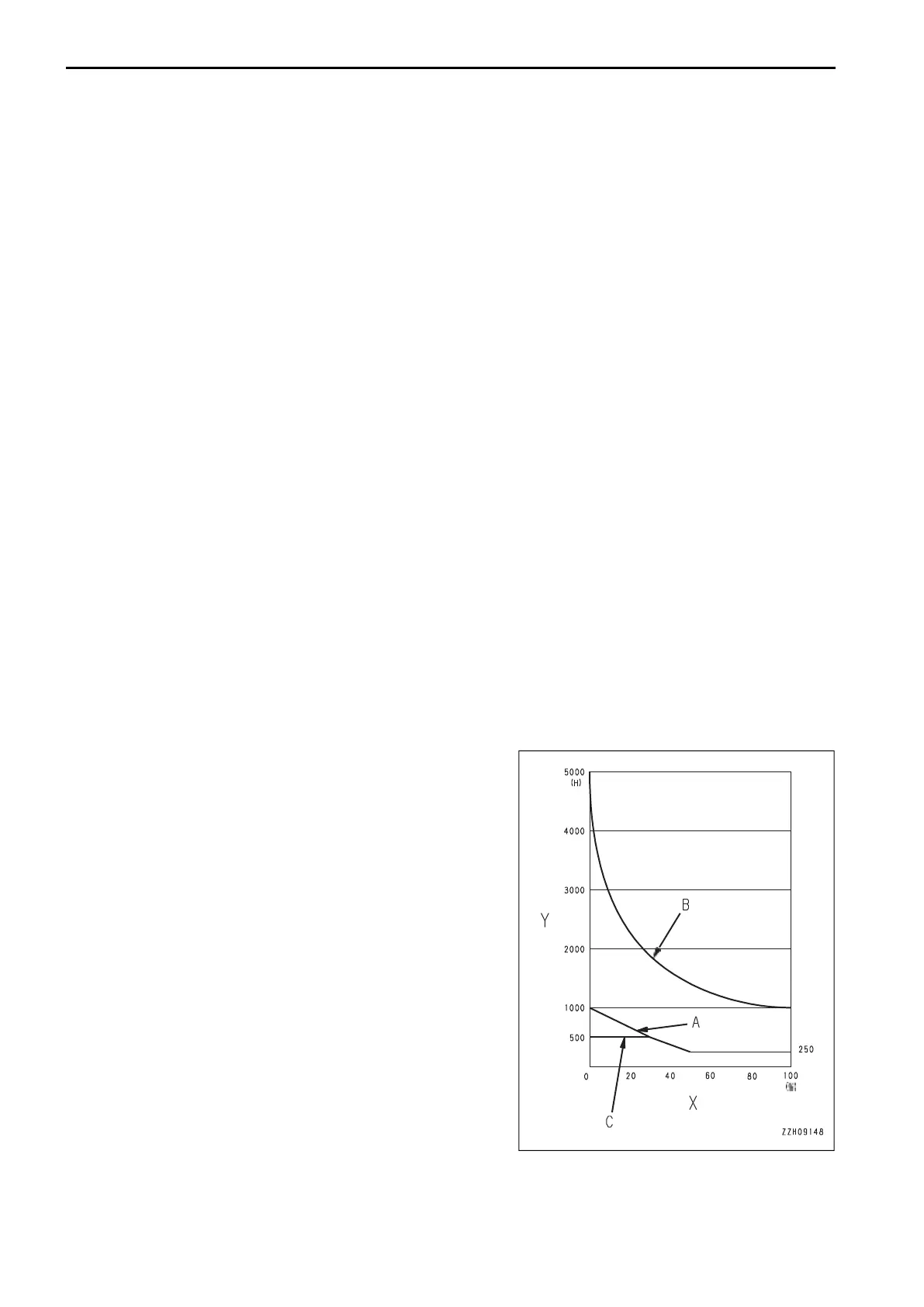

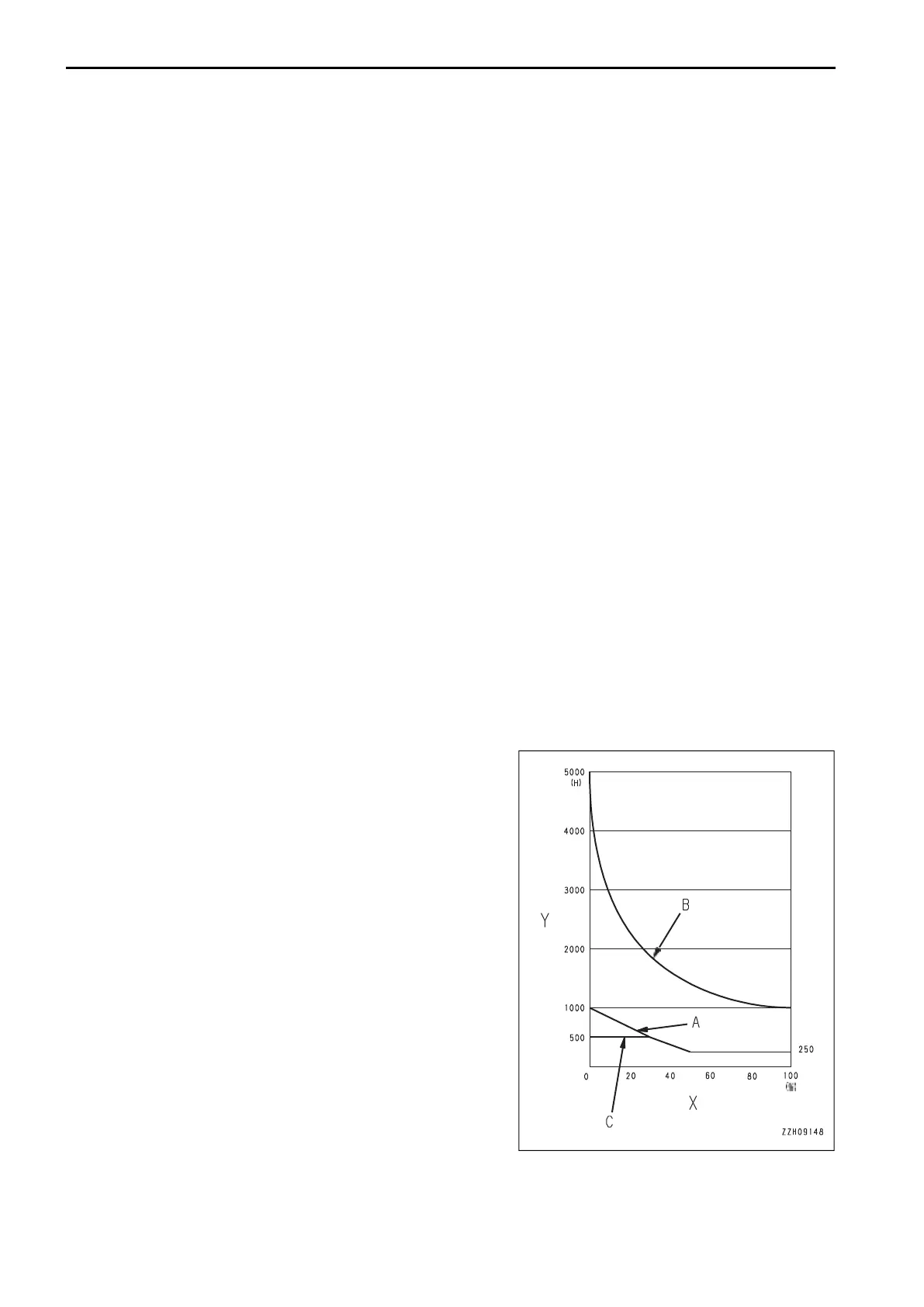

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

For machine equipped with a hydraulic breaker, the hydraulic oil deteriorates faster than for normal bucket dig-

ging operations, so set the maintenance intervals as follows.

Replace hydraulic filter element

On a new machine, replace the element after the first 100 to

150 hours, then perform further replacement of the element ac-

cording to the table.

Change oil in hydraulic tank

Change the oil according to the table.

Replace additional filter element for breaker (if equip-

ped)

Use a guideline of 250 hours for use of the breaker (operating

ratio of the breaker: 50% or more), and replace the element ac-

cording to the table.

X: Breaker operating ratio (%)

Y: Replacement interval (H)

(A):Element of hydraulic tank

(B):Hydraulic oil

(C) :Element of additional filter

REMARK

Breaker operating ratio 100% means that only the breaker is

used

Breaker operating ratio 0% means that the breaker is not used

Loading...

Loading...