5.

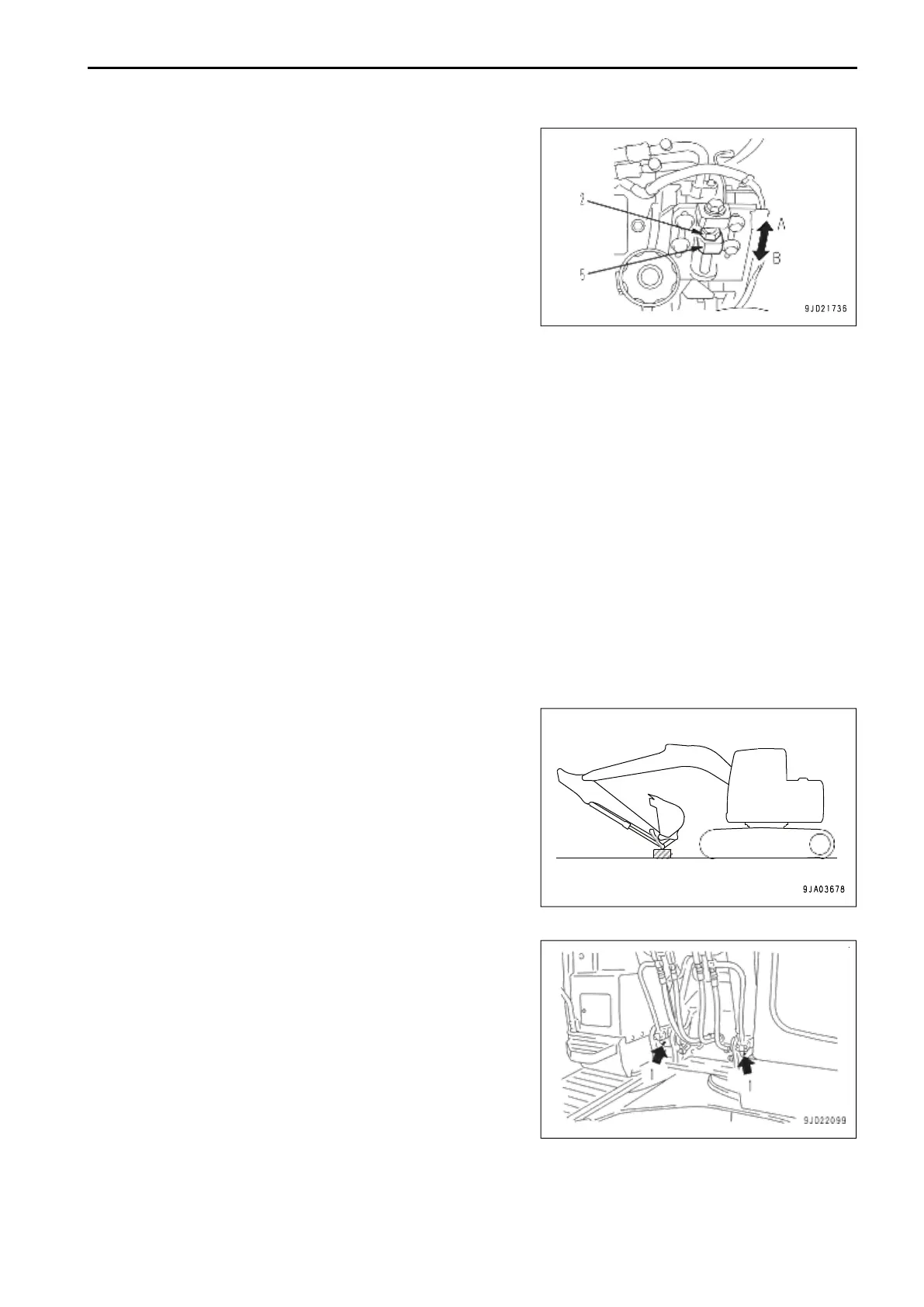

After adjusting the belt tension properly, tighten the nut (2)

until it touches the boss (5) and tighten it further in direc-

tion B so that it does not become loose.

Tightening torque: 108 to 132 Nm

6.

Tighten the bolts (1) (4 pieces) to fix them.

Tightening torque: 58.8 to 73.5 Nm

7.

After fixing, check again that the belt tension is proper.

Adjust it again if the tension is not within the proper range.

8.

Check each pulley for damage, wear of the V-groove, and

the wear of the V-belt. In particular, be sure to check that

the V-belt is not touching the bottom of the V-groove.

9.

Replace the belt with a new one if the belt is stretched and has no allowance for adjustment, or has slipping

sound or squeak because of cuts or cracks of the belt.

NOTICE

• When the new V-belt is installed, readjust it after operating for 1 hour.

EVERY 500 HOURS MAINTENANCE

Maintenance for every 100 and 250 hours should be performed at the same time.

METHOD FOR LUBRICATING

NOTICE

• If any unusual noise is generated from any greasing point, perform greasing regardless of the

greasing interval.

• Perform greasing every 10 hours for the first 50 hours of operation on a new machine.

• After the machine is subjected to digging work in the water, be sure to grease the wet pins.

Prepare a grease pump.

1.

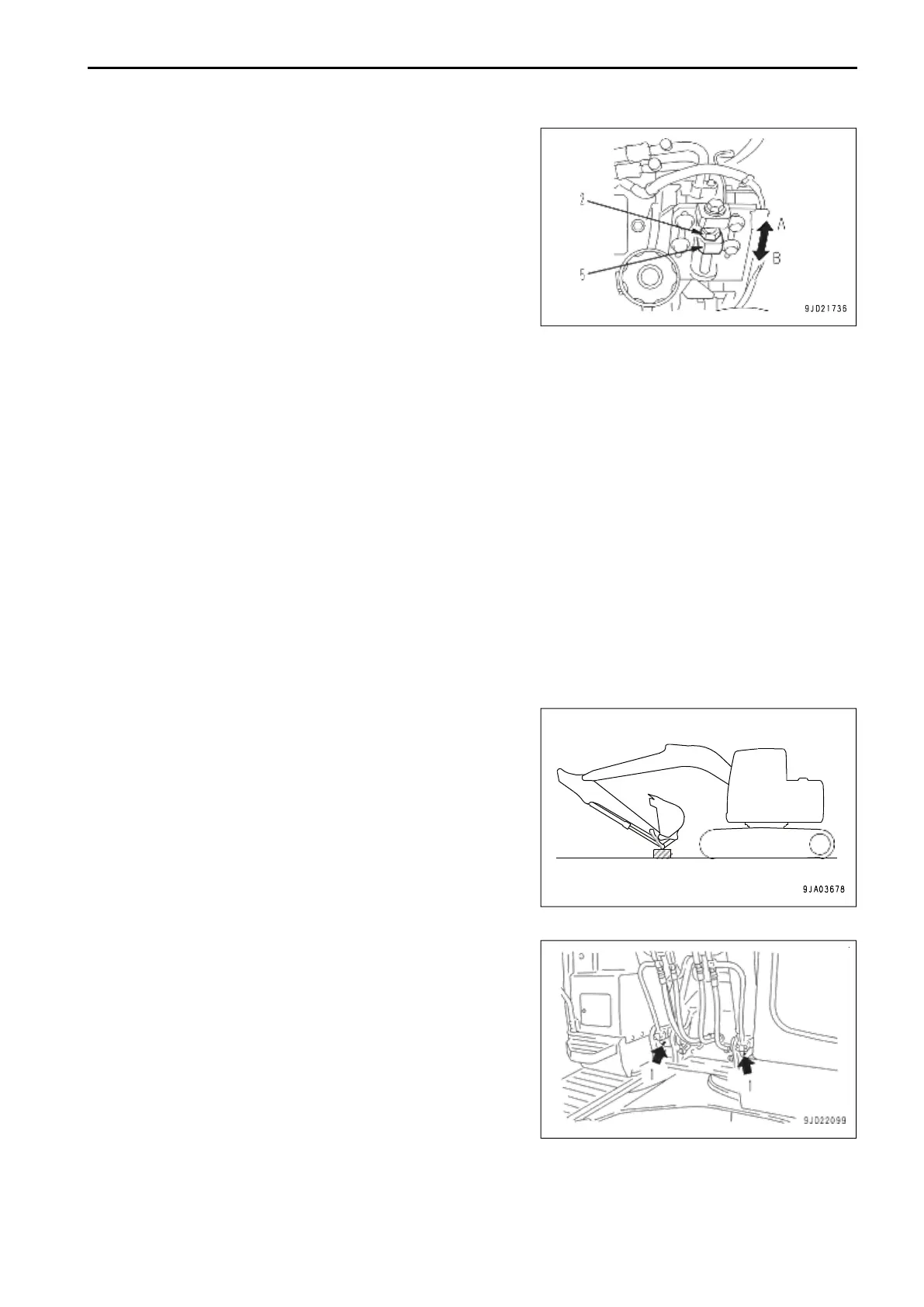

Set the machine to the greasing posture shown on the fig-

ure, lower the work equipment to the ground,and stop the

engine.

2.

By using a grease pump, pump in grease through the grease fitting shown by arrow.

(1) Boom cylinder foot pin (2 places)

Loading...

Loading...