• Be

sure to stop the engine before checking the

oil level.

1. Park the machine on a flat surface.

2. Check the engine oil before starting the engine or 5

minutes or more after the engine has stopped.

3. To check the oil level, pull out the dipstick, wipe it

clean, replace it, and pull it out again. Check to see

that the oil level lies within the crosshatched area.

If the level is too low, add new oil to the prescribed

level at the oil inlet.

(See LUBRICANTS, FUEL AND COOLANT on

page 106.)

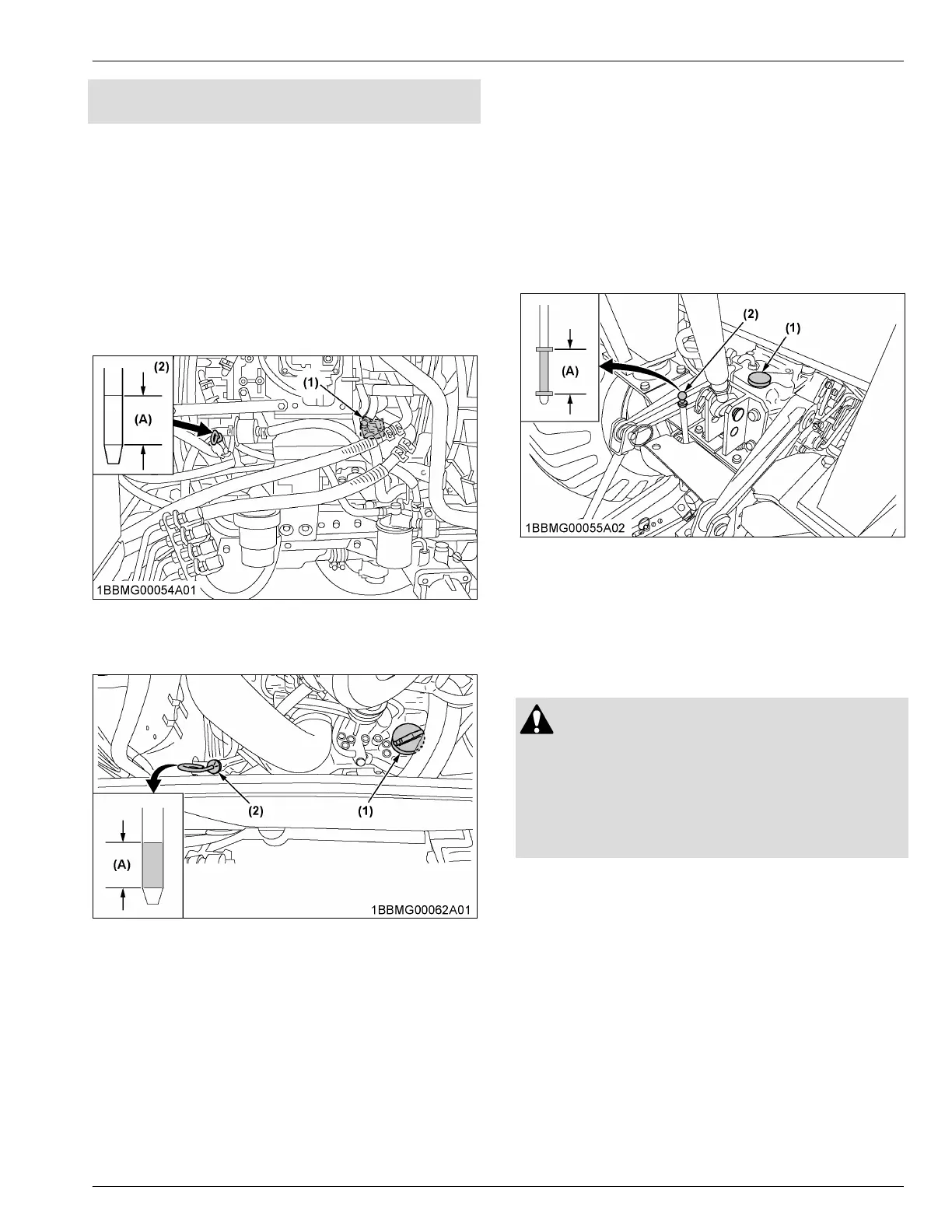

[LX3310]

(1) Oil inlet

(2) Dipstick

(A) Oil level is acceptable within

this range.

[LX2610/LX2610SU]

(1) Oil inlet

(2) Dipstick

(A) Oil level is acceptable within

this range.

IMPORTANT :

• When

using an oil of different manufacturer

or viscosity from the previous one, remove

all of the old oil.

Never mix 2 different types of oil.

• If the oil level is low, do not run the engine.

• In adding engine oil, use a funnel or the like,

which could prevent the oil from getting

splashed on hot spots.

5. Checking transmission fluid level

1. Park

the machine on a flat surface, lower the

implement and shut off the engine.

2. To check the oil level, pull out the dipstick, wipe it

clean, replace it, and pull it out again. Check to see

that the oil level lies within the crosshatched area.

If the level is too low, add new oil to the prescribed

level at the oil inlet.

(See LUBRICANTS, FUEL AND COOLANT on

page 106.)

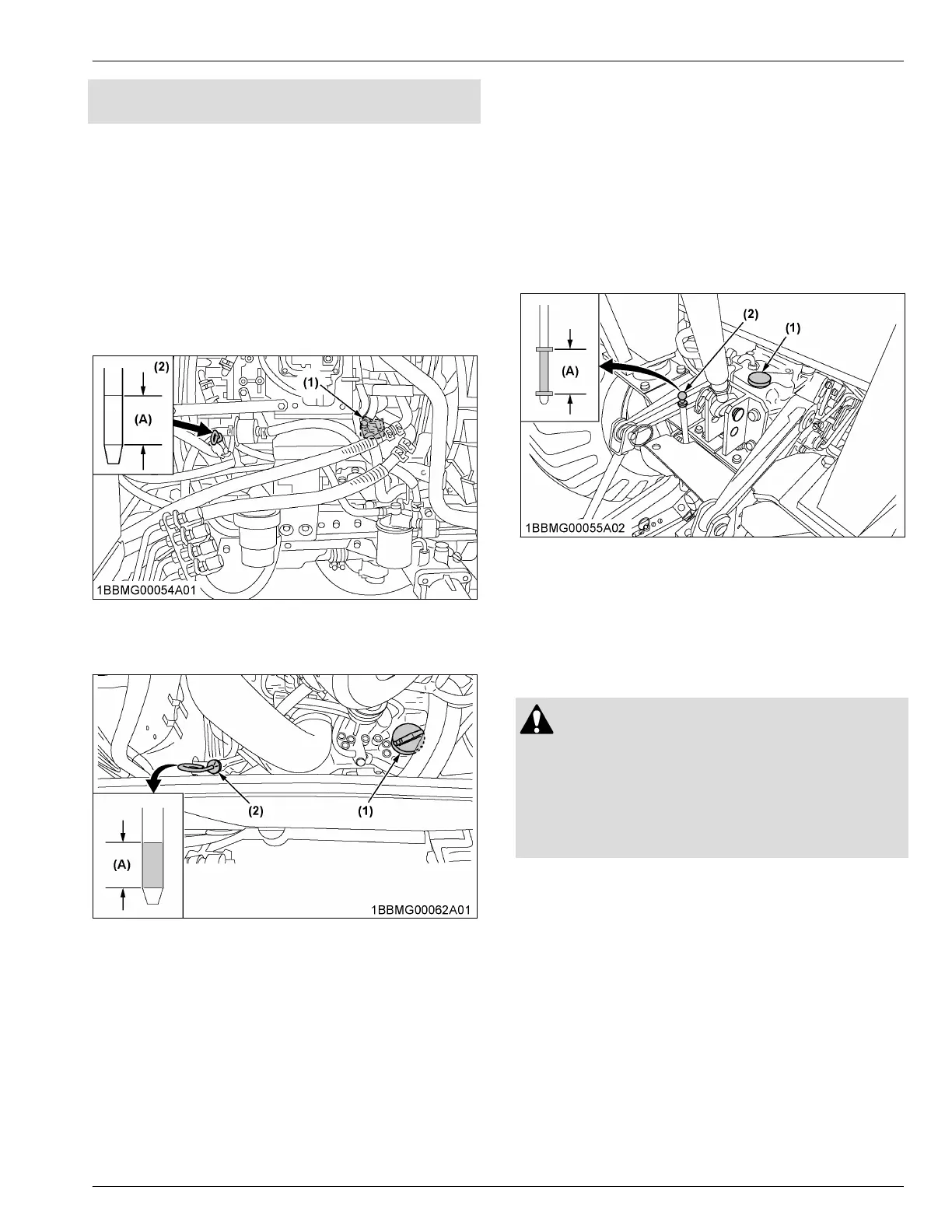

(1) Oil inlet

(2) Dipstick

(A) Oil level is acceptable within

this range.

IMPORTANT :

•

If the oil level is low, do not run the engine.

6. Checking coolant level

WARNING

T

o avoid personal injury or death:

• Do not remove the radiator cap while the

coolant is hot. When cool, slowly rotate the cap

to the first stop and allow sufficient time for

excess pressure to escape before removing the

cap completely.

1. Check

to see that the coolant level is between the

[FULL] and [LOW] marks of the recovery tank.

DAILY CHECK PERIODIC SERVICE

Loading...

Loading...