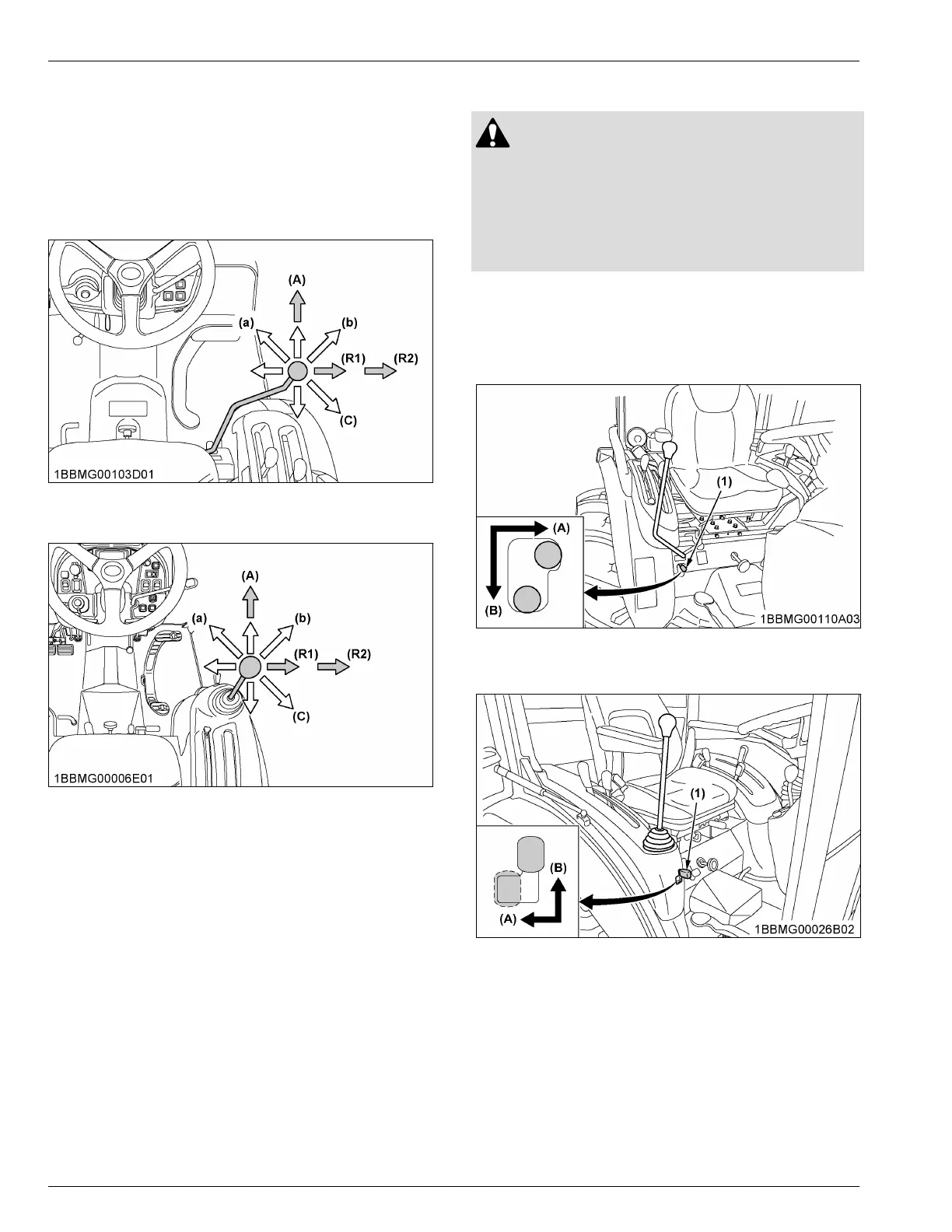

2.3 Loader/remote control valve lever

1. Before

moving the lever, make sure that the

hydraulic hoses for attachments are connected.

2. Move the lever diagonally ((a), (b), (c) shown in the

figure), and the first and second segments can be

controlled simultaneously.

ROPS model

(A) “FLOAT”

CAB model

(A) “FLOAT”

NOTE :

• Move

the lever to the “FLOAT” position, and

it will be held there by the detent

mechanism. To use the valve as a floating

valve with detents, connect the hydraulic

hoses to ports [A] and [B].

• When taking off hydraulic power from port

[D], the flow rate can be adjusted in 2 stages

with the lever.

The flow rate is high at position (R1) and low

at position (R2). Move the lever to position

(R1) or (R2) depending on the attachment in

use.

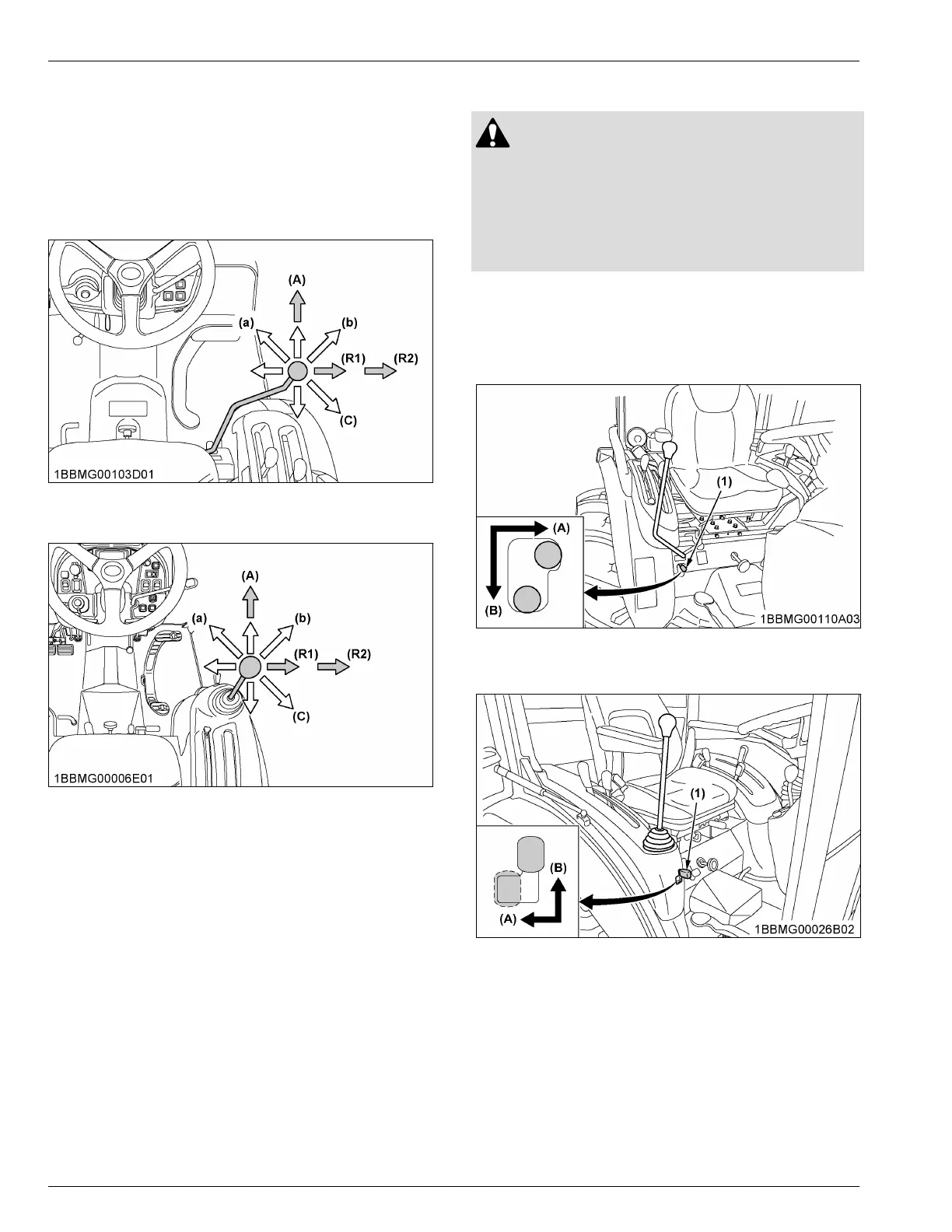

2.4 Valve lock

WARNING

T

o avoid personal injury or death from crushing:

• Do not utilize the valve lock for machine

maintenance or repair.

• The valve lock is to prevent accidental actuation

when implement is not in use or during

transport.

The control valve is equipped with a valve lock feature.

The control valve is locked in the “LOCK” position.

The lock is not intended and will not prevent a leak

down of the implement during the period of storage.

ROPS model

(1) Lock lever (A) “UNLOCK”

(B)

“LOCK”

CAB model

(1) Lock lever (A) “UNLOCK”

(B)

“LOCK”

REMOTE HYDRAULIC

CONTROL SYSTEM (IF

EQUIPPED)

The hydraulic auxiliary control valves can be installed

with up to 2 segments.

HYDRAULIC UNIT AUXILIARY HYDRAULICS

Loading...

Loading...