Technical Information

81

PW 6xx7

If the programmer selects “user-defined” and programs water inlet valves 1 to 4,

then generally optimal water intake (without additional heating) will not occur. If

the programmer selects only hot-water valves and/or forces a rise above the

target temperature, the control reacts with a cold-water intake via the following

alternative valves:

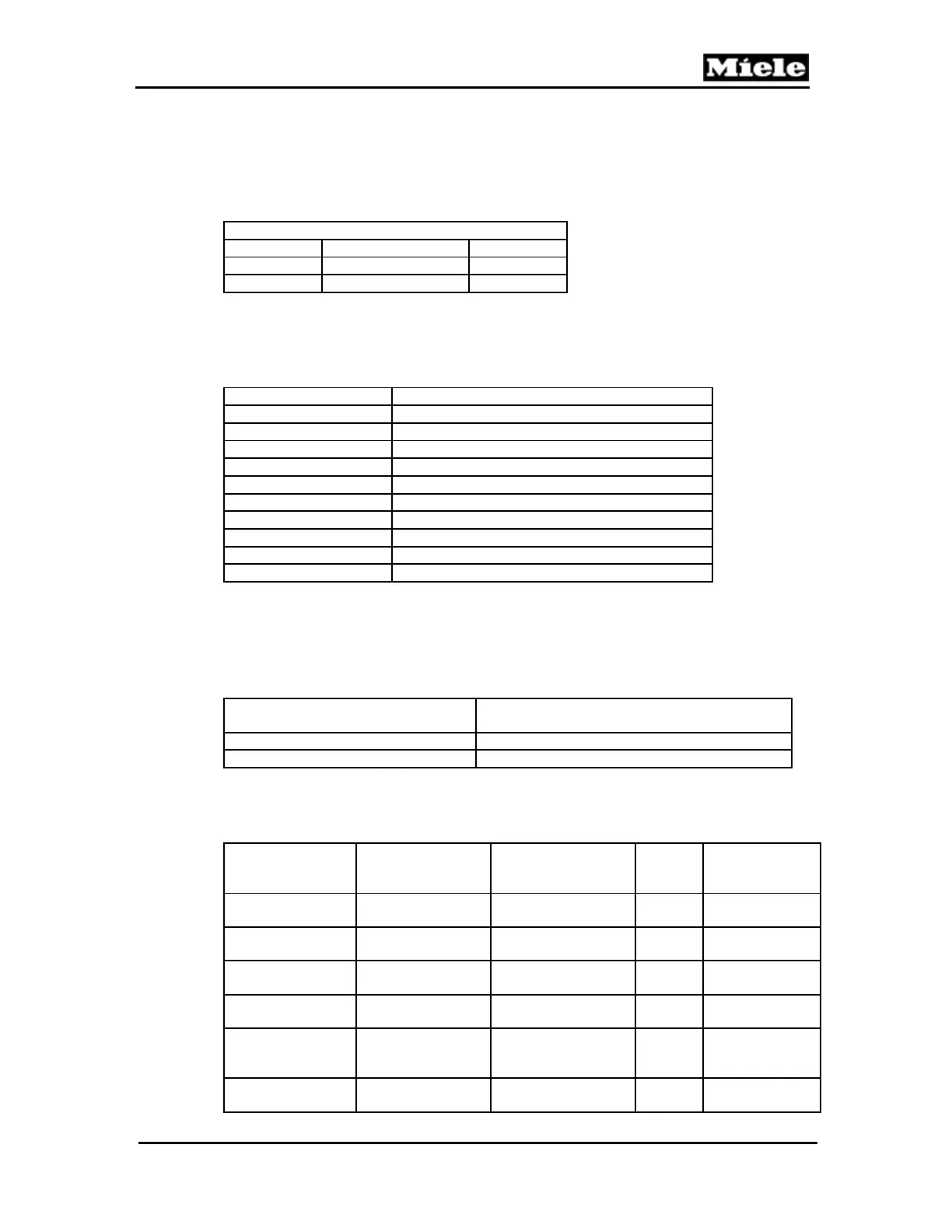

Actual temperature > Target temperature

W1 Substituted with K1

W2 Substituted with K2

WD Substituted with KD

Table 100-29: If the target temperature is exceeded, the control automatically opens

cold-water valves instead of hot-water valves.

If valves are programmed for the water intake that do not exist in the machine,

the control substitutes these for others as shown in the following table:

Programmed valve Substitute valve activated by control

K1 KD

K2 KD

K3 KD

K4 KD

K6 KD

KD K1

KH KD

W1 WD

W2 WD

WD W1

Table 100-30: List of Substitute Valves if Programmed Valve is Not Available

After the target level has been reached, valves K3 and K4 should not be

activated during any additional intake. If the programmer has selected only

these valves, the control will operate substitutes as shown in the following

table:

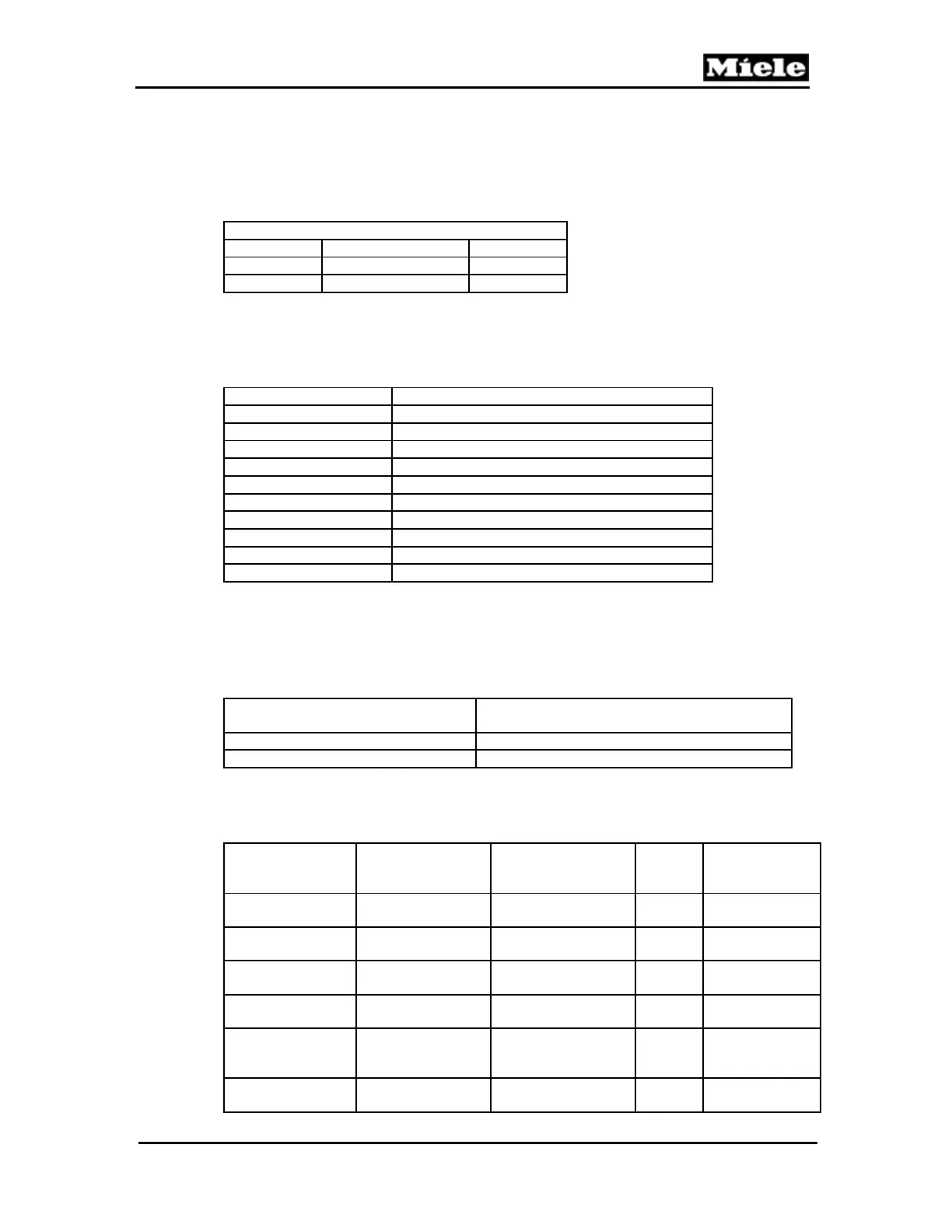

Programmed valve - Water intake 1 Substitute valve activated by control during

additional intake

K3 KD

K4 KD

Table 100-31: List of Substitute Valves for Additional Intake after Target Level

Reached

Inlet valve summary:

Designation on

wiring diagram

Description Detergent

dispenser

compartment

Symbol Designation in

software/

documentation

1Y5 Inlet valve – Cold,

hard water, direct

- - HAW, optional

hard water kit

2Y5 Inlet valve – Cold,

hard water direct

- - HAW, optional

hard water kit

1Y6 Inlet valve – Cold

water pre-wash

1

K1 / KAW1

2Y6 Inlet valve – Cold

water, main wash

2

K2 / KAW2

3Y6 Inlet valve – Cold

water, rinses –

Fabric conditioner

3, at front

K3 / KAW3

1Y9 Inlet valve – Hot

water, pre-wash

1

W1 / WAW1

Loading...

Loading...