2-58

POWER TRAIN

-

Automatic Transaxle

Underdrive

clutch

Underdrive

solenoide

(de-energized)

2-4/Law-reverse

solenoid

(energized)

Orifice located

in piston

Reverse

-

1

. .

Torque converter

apply pressure

~-~/LOW

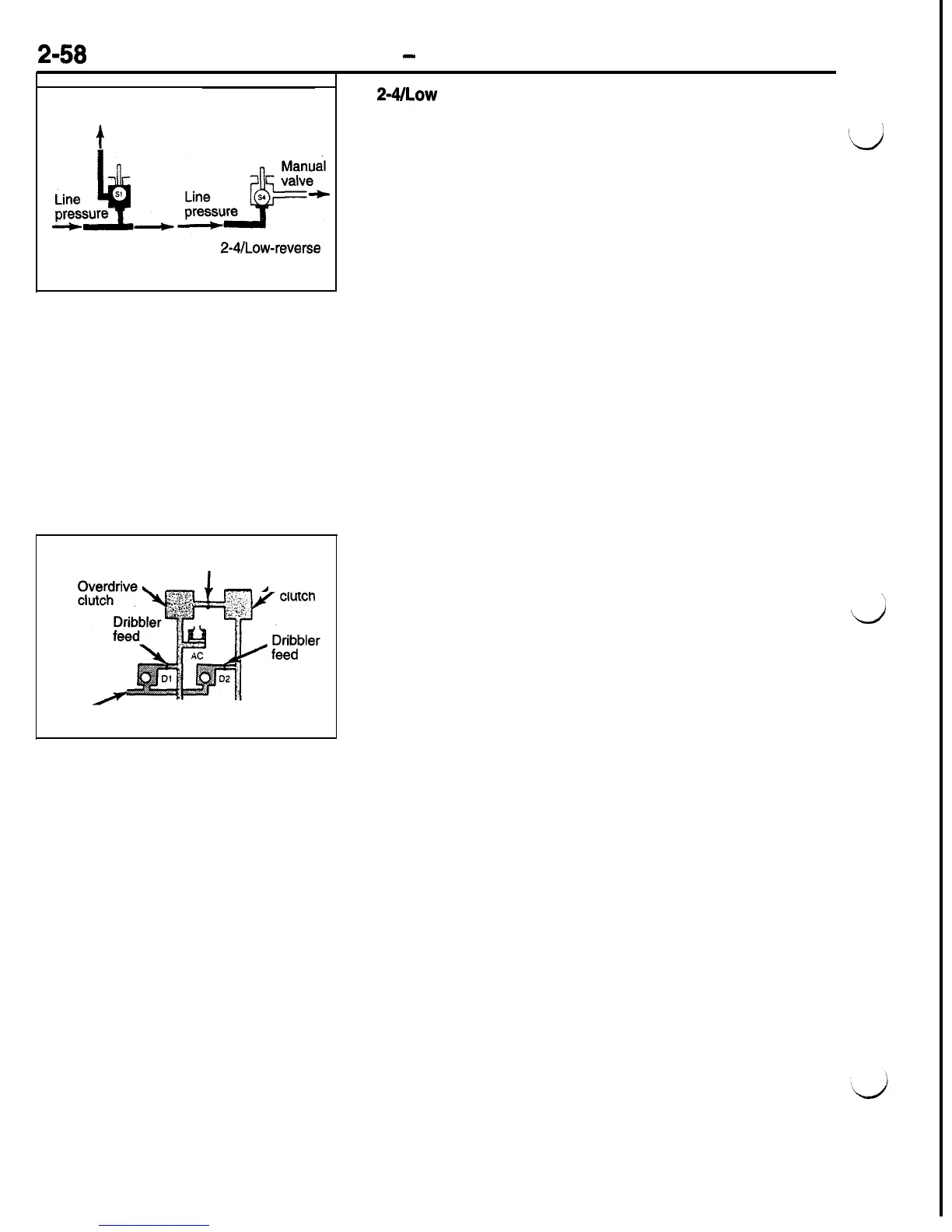

Reverse and Underdrive Solenoids

When these two solenoids are not energized by the TCM,

their check balls prevent venting of a clutch. In this position

‘d

the check balls allow line pressure to reach the desired clutch.

These solenoids allow oil pressure to the clutch when de-ener-

gized and are referred to as normally applied valves. When

the solenoids are energized, the plunger forces the check ball

down and prevents line pressure from reaching the clutch.

At the same time, pressure is vented from the clutch.

Similar to the normally vented valves, these normally applied

valves are also cycled to modulate clutch pressure to any

value between line pressure and zero.

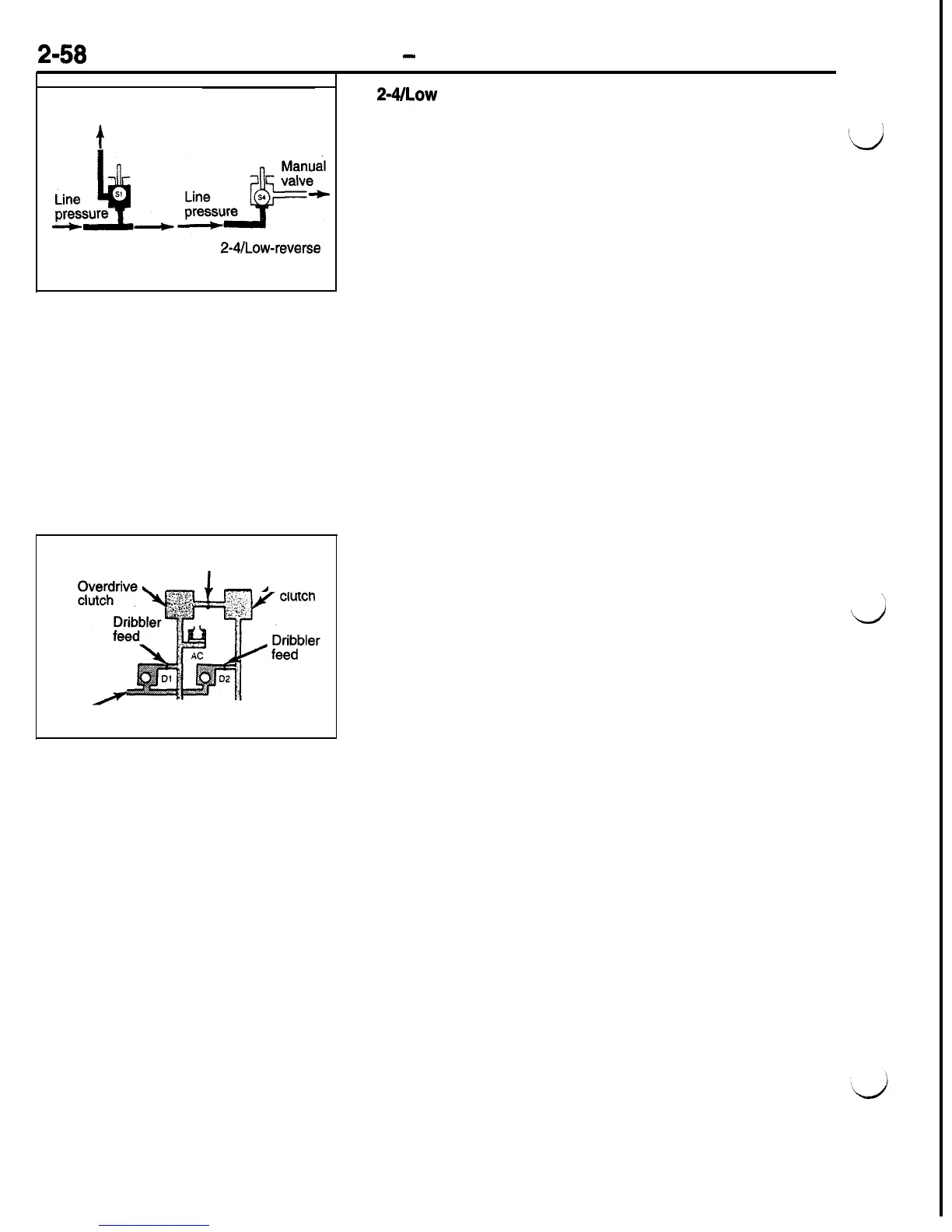

Dribbler Circuits

Two dribbler circuits feed low flow rate oil (residual pressure)

from the torque converter to the overdrive and reverse clutches

at all times. The low flow rate oil provided by the dribbler circuits

keeps both clutches full of oil. These clutches share a common

d

piston. If there is a difference in the amount of oil on either

side of the piston, the piston would tend to move toward the

clutch with less oil and cause that clutch to drag. If oil is only

on one side of the piston, and the retainer is spinning at high

speed, the spinning action will force oil to the outer diameter

of the retainer and cause the piston to move. The oil pressure

build-up caused by spinning is called centrifugal pressure.

Another feature added to avoid this situation is a small orifice

in the overdrive/reverse piston that helps equalize pressure

on both sides of the piston. The dribbler circuits only involve

low flow rates, which do not have any significant effect when

the clutches receive full line pressure.

Loading...

Loading...