ENGINE <NON-TURBO>

-

Control System

I-25

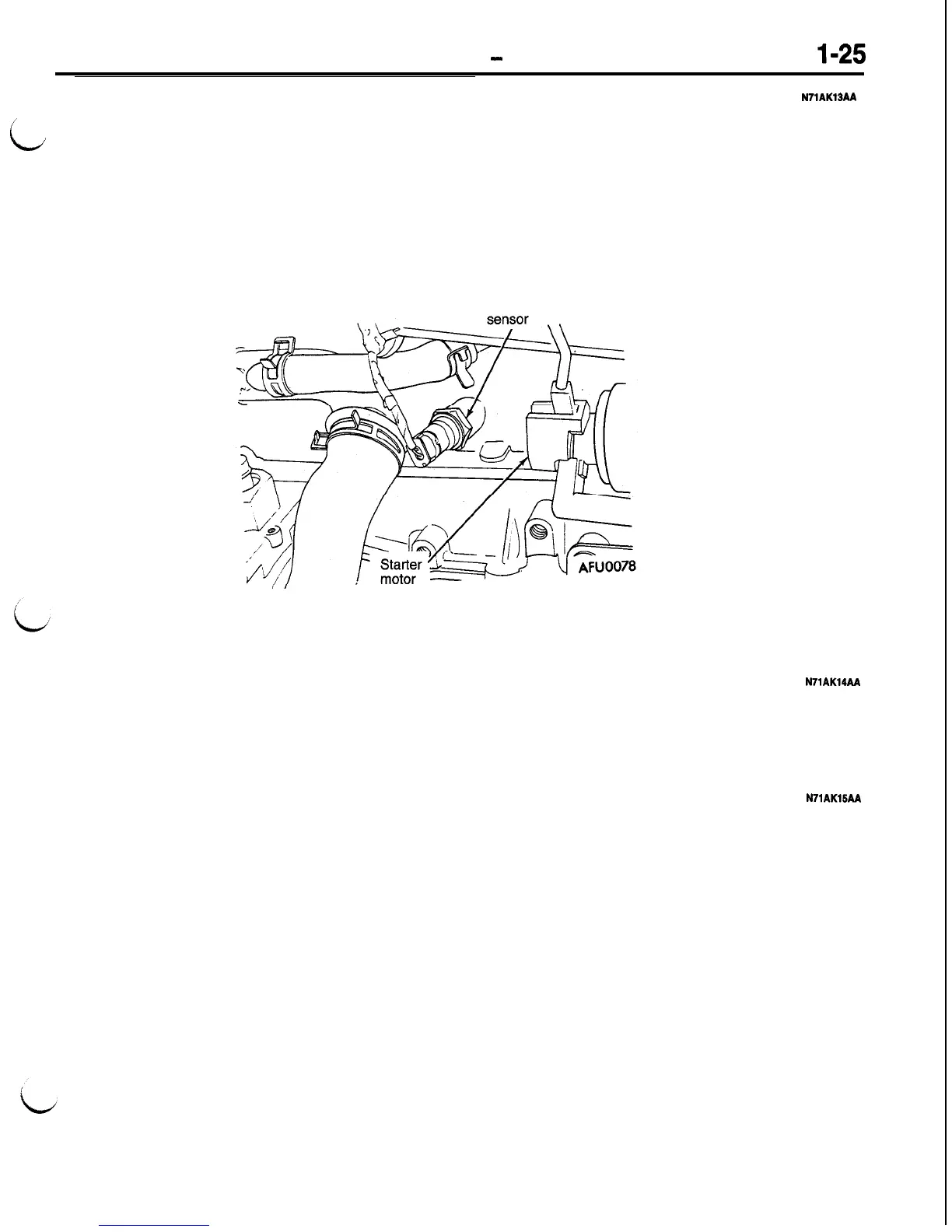

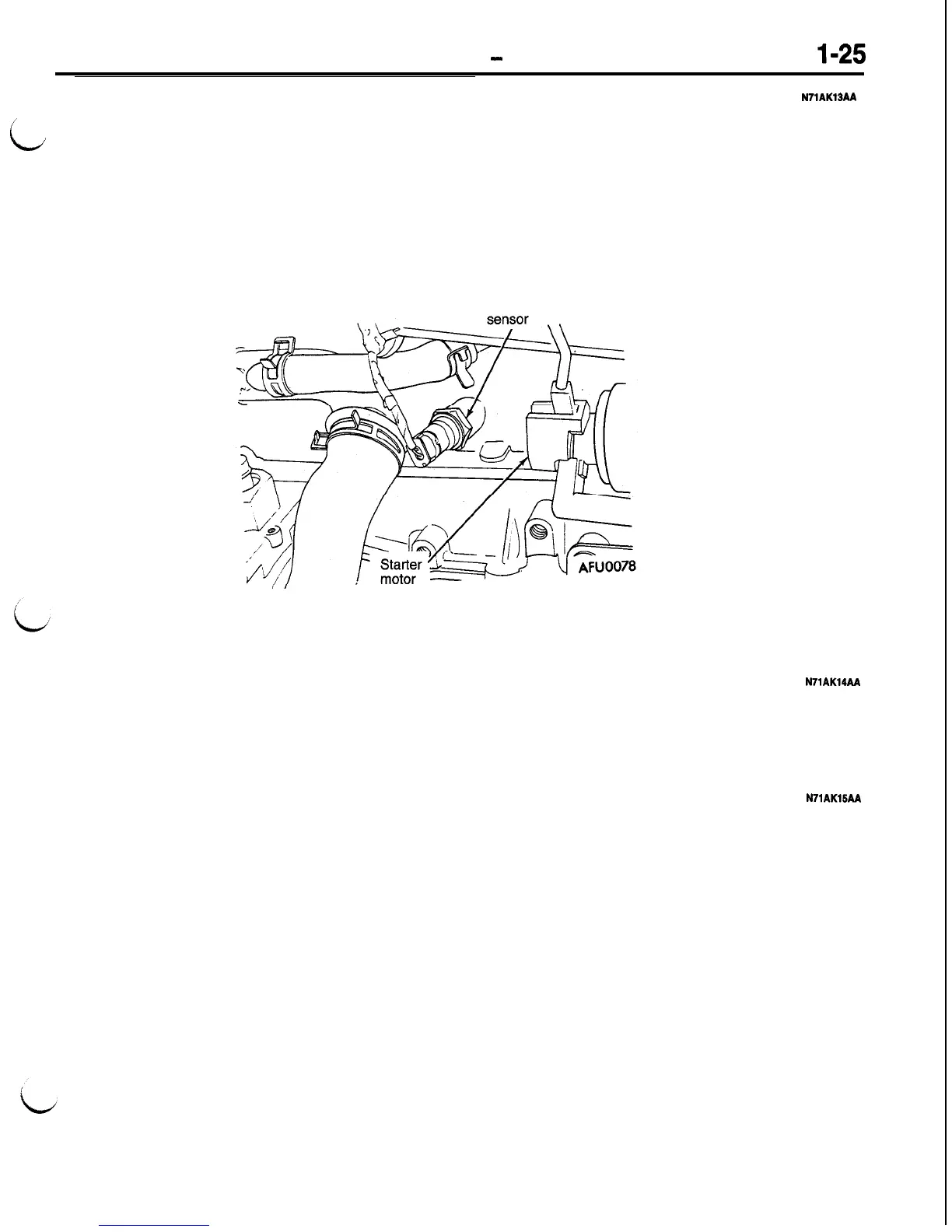

KNOCK SENSOR

N7lAK13AA

The knock sensor threads into the side of the cylinder

Knock sensors contain a piezoelectric material

j

block below the intake manifold. When the knock

which constantly detects engine knock vibration and

sensor detects a knock in one of the cylinders, it

sends an input voltage (signal) to the PCM while

sends an input signal to the PCM. In response,

the engine operates. As the intensity of the engine

the PCM retards ignition timing for all cylinders by

knock increases, the knock sensor output voltage

a scheduled amount.

also increases.

Knock

BRAKE SWITCH

When the brake switch is activated, the power-train

control module (PCM) receives an input indicating

that the brakes are being applied. After receiving

this input the PCM maintains idle speed to scheduled

N71AKl4AA

RPM through control of the idle air control motor.

The brake switch is mounted on the brake pedal

support bracket.

BATTERY VOLTAGE

The power-train control module (PCM) monitors the

battery voltage input to determine fuel injector pulse

width and generator field control. If battery voltage

N71AK15AA

is low the PCM will increase injector pulse width

(period of time that the injector is energized).

Loading...

Loading...