ENGINE <NON-TURBO>

-

Control Svstem

Operation

Once it reaches its operating temperature of

572”

to

662”F,

the sensor generates a voltage inversely

proportional to the amount of oxygen in the exhaust.

This information is used by the PCM to calculate

the fuel injector pulse width necessary to provide

the critical 14.7 to 1 air/fuel ratio (stoichiometric).

A properly operating sensor must not only be able

to generate an output voltage across its operating

range of 0 to 1 volt as it is exposed to different

02

levels, it also must be able to detect these

changes quickly. To detect a shift in the air/fuel

mixture (lean or rich) the output voltage must change

beyond a threshold value. A malfunctioning sensor

could have difficulty changing beyond the threshold

value.

While there are existing tests that determine if an

02

sensor is shorted to voltage, contains an open

circuit, or does not function at all, prior to OBD

II, it was impossible to identify sluggish or marginal

sensors.

A slow response rate or reduced voltage output

are all signs of an improperly operating oxygen sen-

sor. This could mean longer instances of combustion

of less than optimum air/fuel mixtures. This can

significantly increase emissions.

The

02

sensor must have a voltage output of greater

than

.67

volt in order to pass the test. It must also

switch more times over a 120 second period than

a given threshold (to demonstrate quick response)

or produce a given number of steep slope switches

(demonstrating dynamic range and quick response)

over the same time period. Data is not stored unless

idle time exceeds 10 seconds.

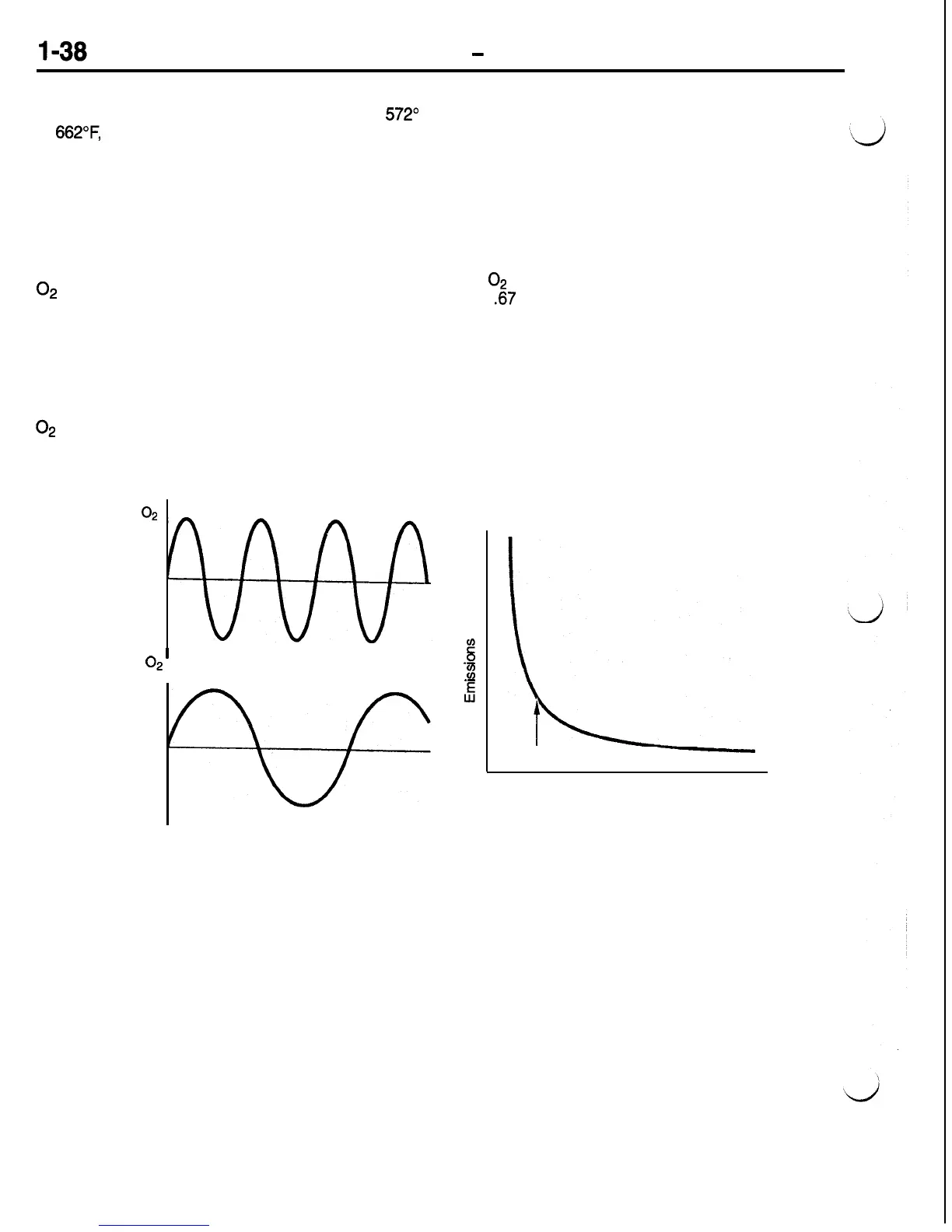

Front

02

High switching

frequency

fast response

Front

O2

’

I

Low switching

frequency

slow response

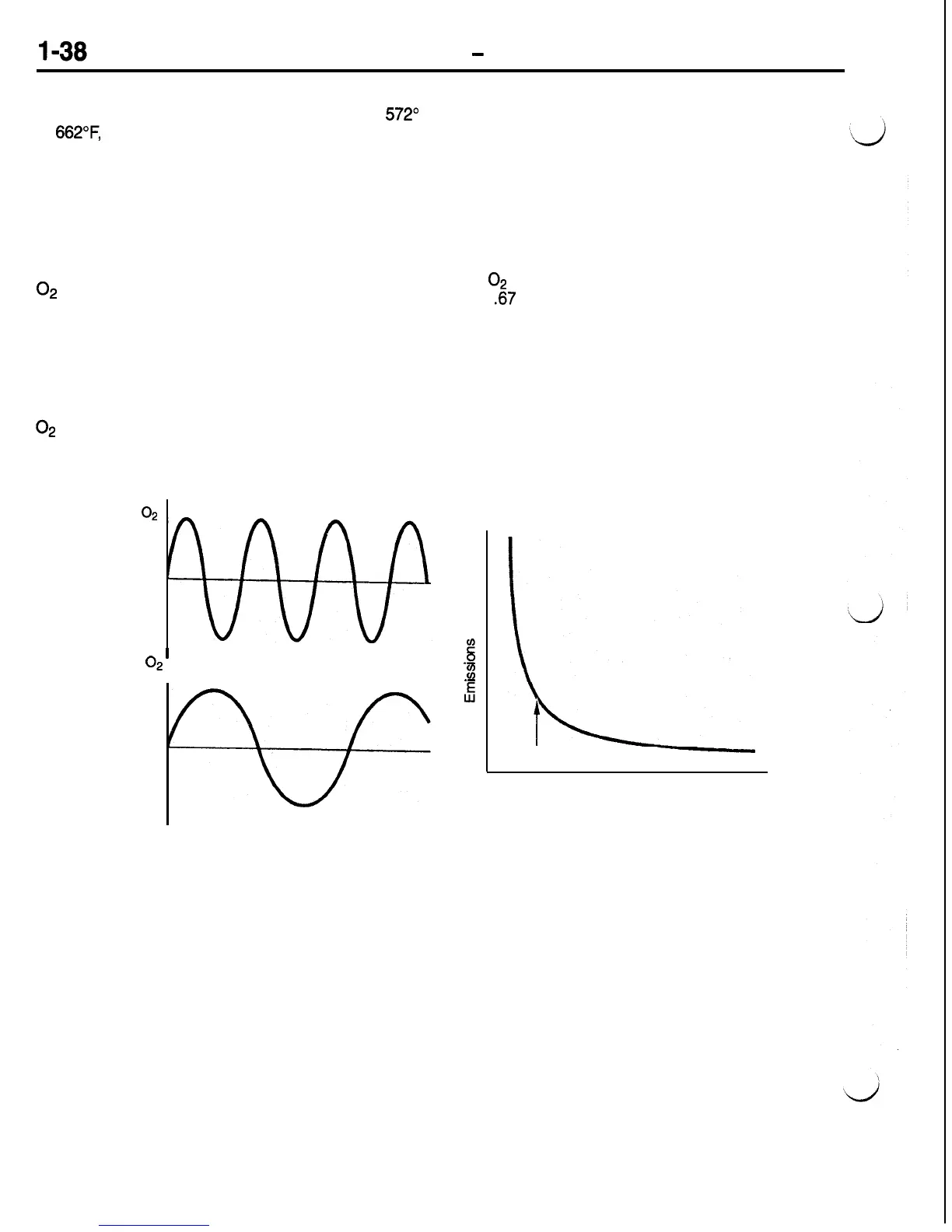

E

.Q

2

.-

WE

Trigger 1.5 x STD

Switching frequency

AFUOO88

Loading...

Loading...