2-90

POWER TRAIN

-

Automatic Transaxle

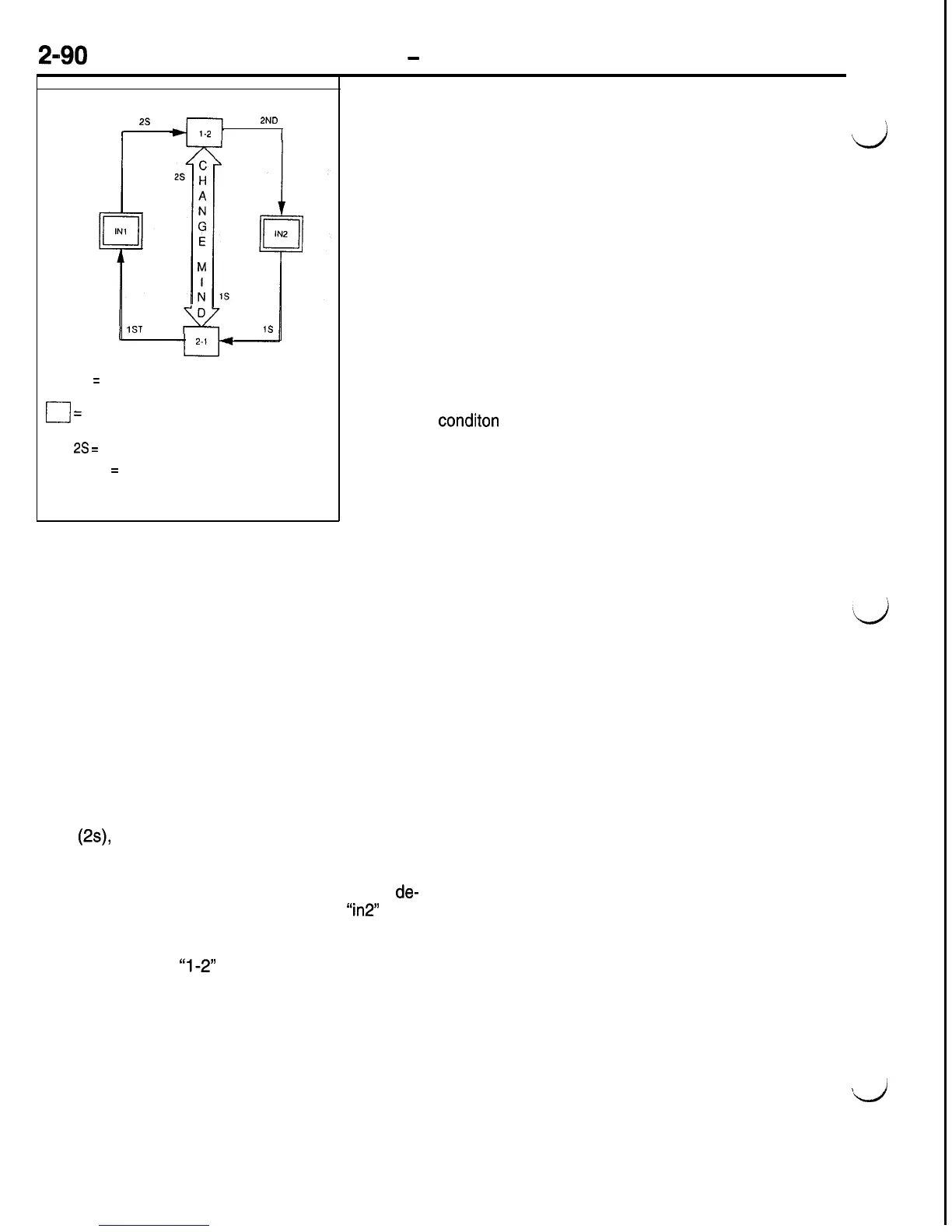

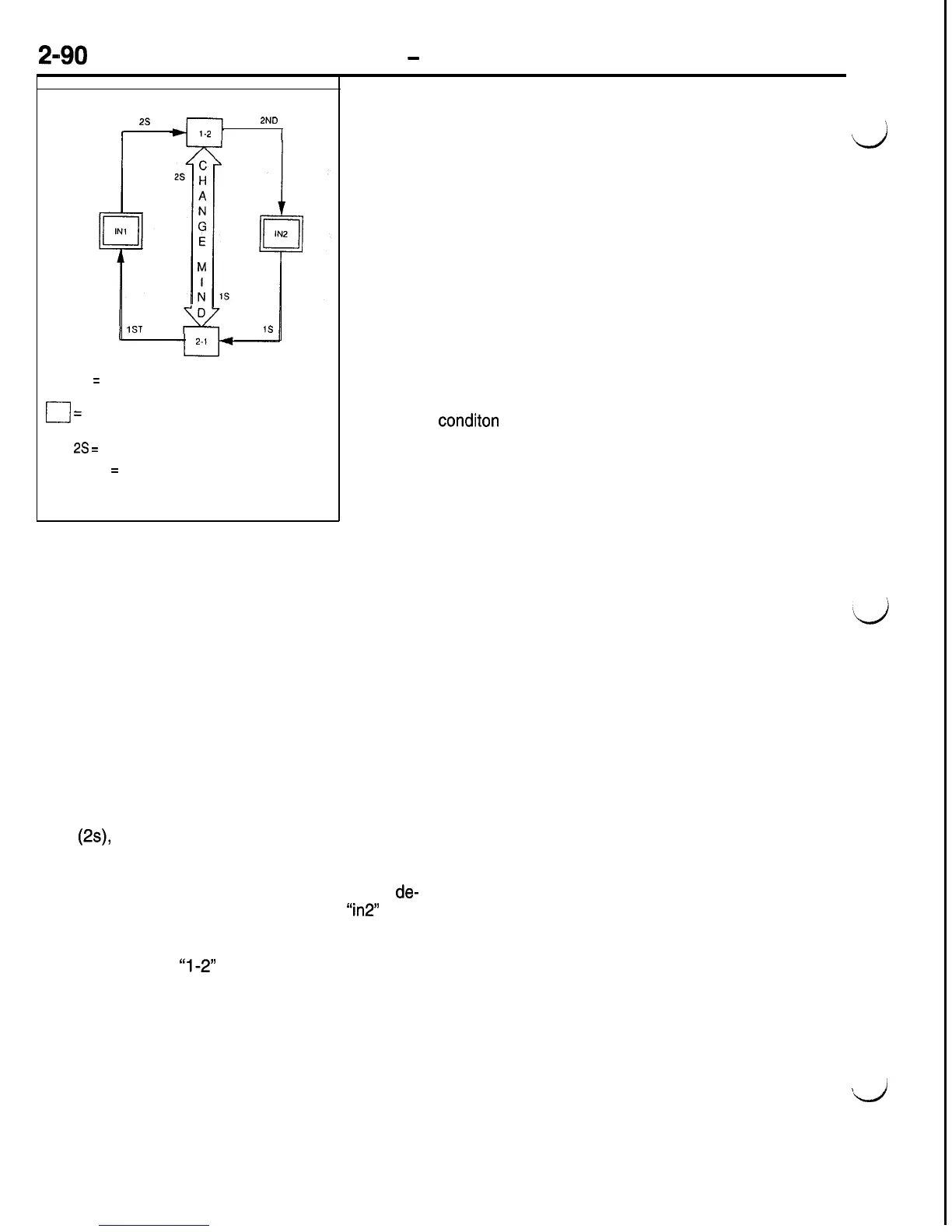

2s

2ND

I

1ST

1s

q

=

In-gear logic

n

=

Shift logic

1 S,

2s

=

Shift schedule output

1 ST, 2ND

=

Speed ratio shift

complete signal

Shift Logic Selection

The purpose of the Shift Logic Selection program is to activate

the appropriate “shift logic” so that the “in-gear logic” condition

d

matches the gear called for by the shift schedule (driver selected

gear, throttle position).

Imagine that the TCM must always be in one of the logic boxes

at any given time. The double line boxes represent the “in-gear

logic” the TCM uses to maintain a certain gear range. The

single line boxes represent the “shift logic” required by the

TCM to execute a desired gear change from one gear to another.

The paths (lines with arrows) between the blocks are labeled

with one or more of the shift schedule output signals (Is, 2s).

These desired gear signals (shift schedule output signals) be-

come the primary input which will cause the correct path to

be taken, from one in-gear box (such as inl) to a shift logic

box (such as l-2).

The output is a change to “shift logic” in order to obtain an

in-gear

conditon

that matches the output of the shift schedule

routine. The TCM knows whether the desired shift has been

completed when a correct speed ratio check of the input and

output speed sensors is present. The speed ratio check is

used to verify that the desired gear has been achieved. For

example, when the correct speed ratio signal for second gear

has been verilied by the TCM by checking the speed ratio

between the input and output speed sensors, it will switch

to the appropriate in-gear logic (in2).

Changes to “In Gear” or “Shift” Logic

If the transaxle is in first gear logic (inl) and the

shift schedule output changes to call for second

gear

(2s),

then “1-2” logic will be activated. This

generally remains in effect until the completion of

the shift is determined by the speed ratio check.

When the speed ratio check confirms that the

de-

gired gear (second) has been obtained,

‘in2”

logic

is activated. There are other possible exits or

changes that may be made to the normal shift sched-

ule logic from the

“1-2”

shift logic example, such

as a change-mind condition.

A “change-mind” shift condition may occur when

a shift that has begun directly from within another

Shift Logic Chart

Another exit or change to the normal shift schedule

logic is the fail shift timer may expire. The TCM

will only allow a certain amount of time to elapse

for the shift logic to complete a shift. If a speed

shift, instead of from an in-gear condition. A “change

mind” condition occurs if a change in the throttle

position signal causes the normal shift schedule

routine to select a different desired gear signal, such

as is, during a 1-2 shift change. These shifts are

accommodated by direct paths between upshift and

downshift logic within the logic selection routine.

“Change mind” shifts are needed to provide the

proper response to changes in driver demand.

Changes in the manual lever (selector lever) position

may also cause a “change-mind” shift depending

on when the lever position changes. A more detailed

shift logic chart is illustrated.

ratio check does not confirm the completion of an

attempted shift within this time limit, the shift logic

’

d

is aborted, and the desired in gear logic is activated.

Loading...

Loading...