ENGINE

<NON-TURBO>

-

Mount

1-61

MOUNT

<I

id

,

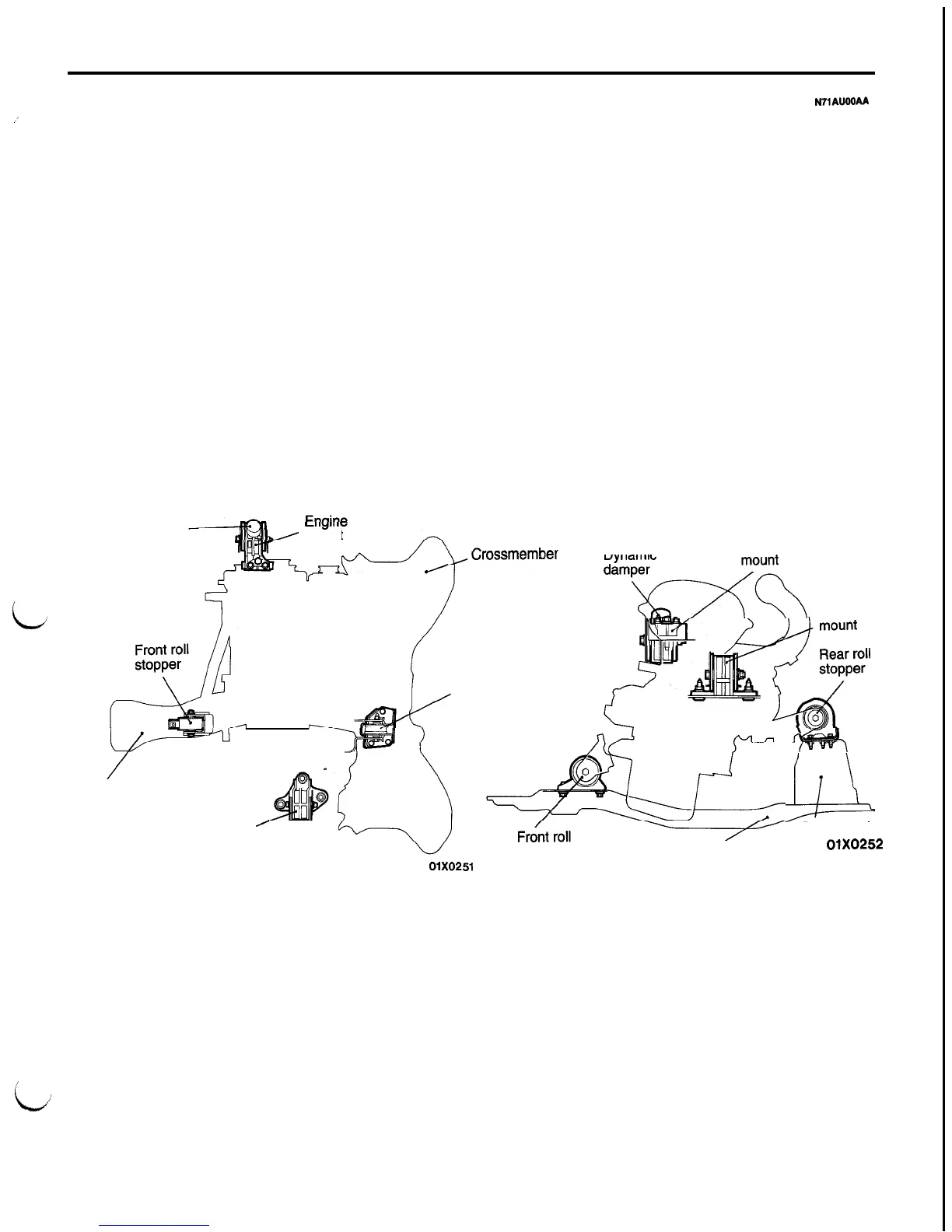

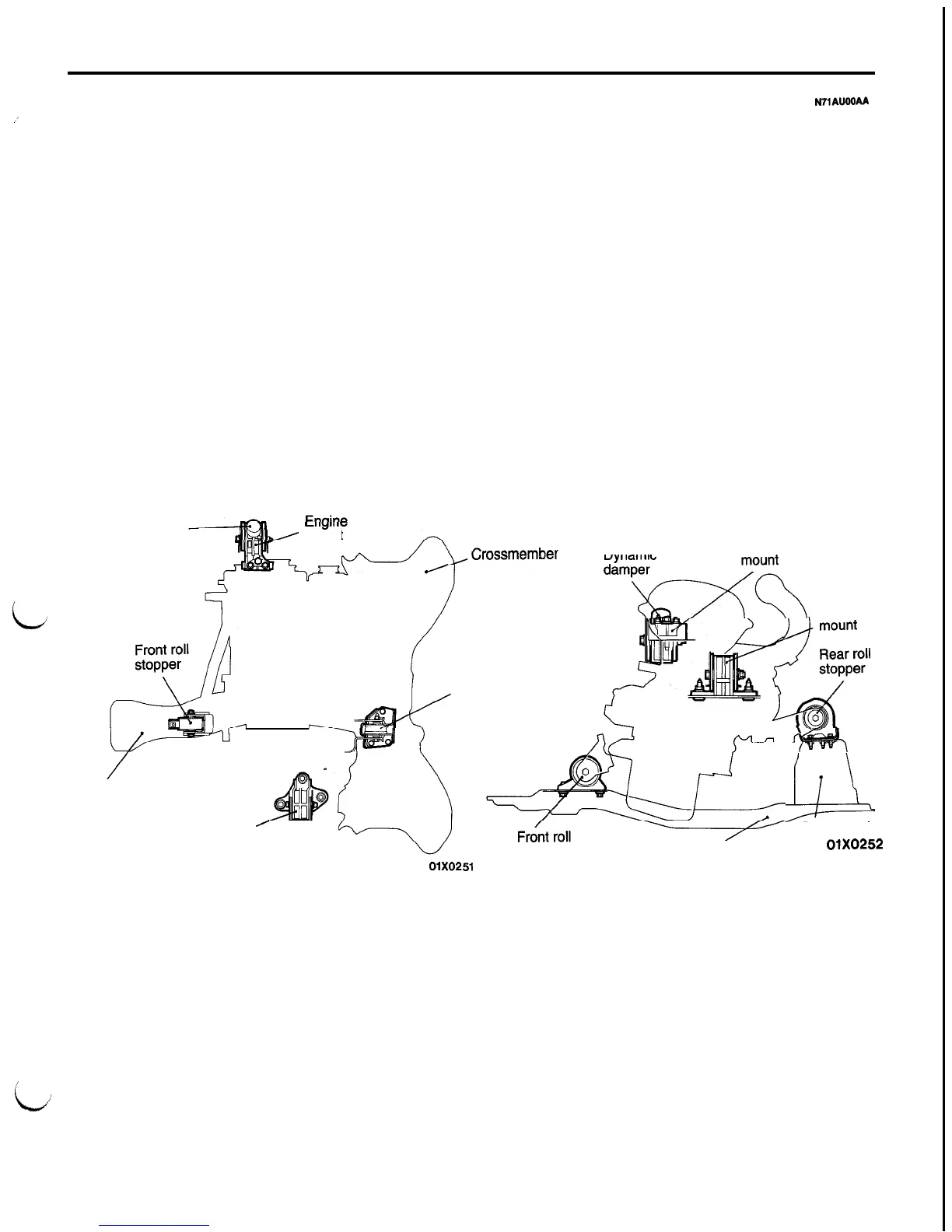

The engine mounts use a principal axis inertia sup-

port system.

This support method on the principal axis inertia

is a structure that supports the top of the engine

FEATURES

l

The mount elements are arranged near the roll

axes of the engine and transaxle so that the

rolling moment can be limited and vibrations

can be reduced during idling.

l

The front and rear roll stopper brackets have

been relocated to the transaxle housing. As

a result, the bracket has been made shorter

and more rigid, which contributes to less vibra-

tion and noise.

l Each insulator with internal hollows has out-

standing vibration absorbing characteristics.

N?‘1AUOOAA

and top of the transaxle to effectively control engine

vibration.

l

Brackets cast from aluminum are used for the

engine mounts and transaxle mounts so as to

reduce booming noise.

l

Conventional arrangement of the engine and

transaxle has been reversed to mount the en-

gine on R.H. side of the vehicle and the transaxle

on the L.H. side, resulting in reversal of the

positions of the respective mounts.

L

Dynamic

damper

LI

,yu

1.z

H

mount

b

wossmemuer

Dynamic

Engine

damp&&

Transaxle

Front

Rear roll

stopper

Centermember

Transaxle

I

mount

01X0251

stopper

Centermember

u

Crossmember

01X0252

i

:

Loading...

Loading...