5-22

Chapter 5 DISASSEMBLY OF BASIC ENGINE

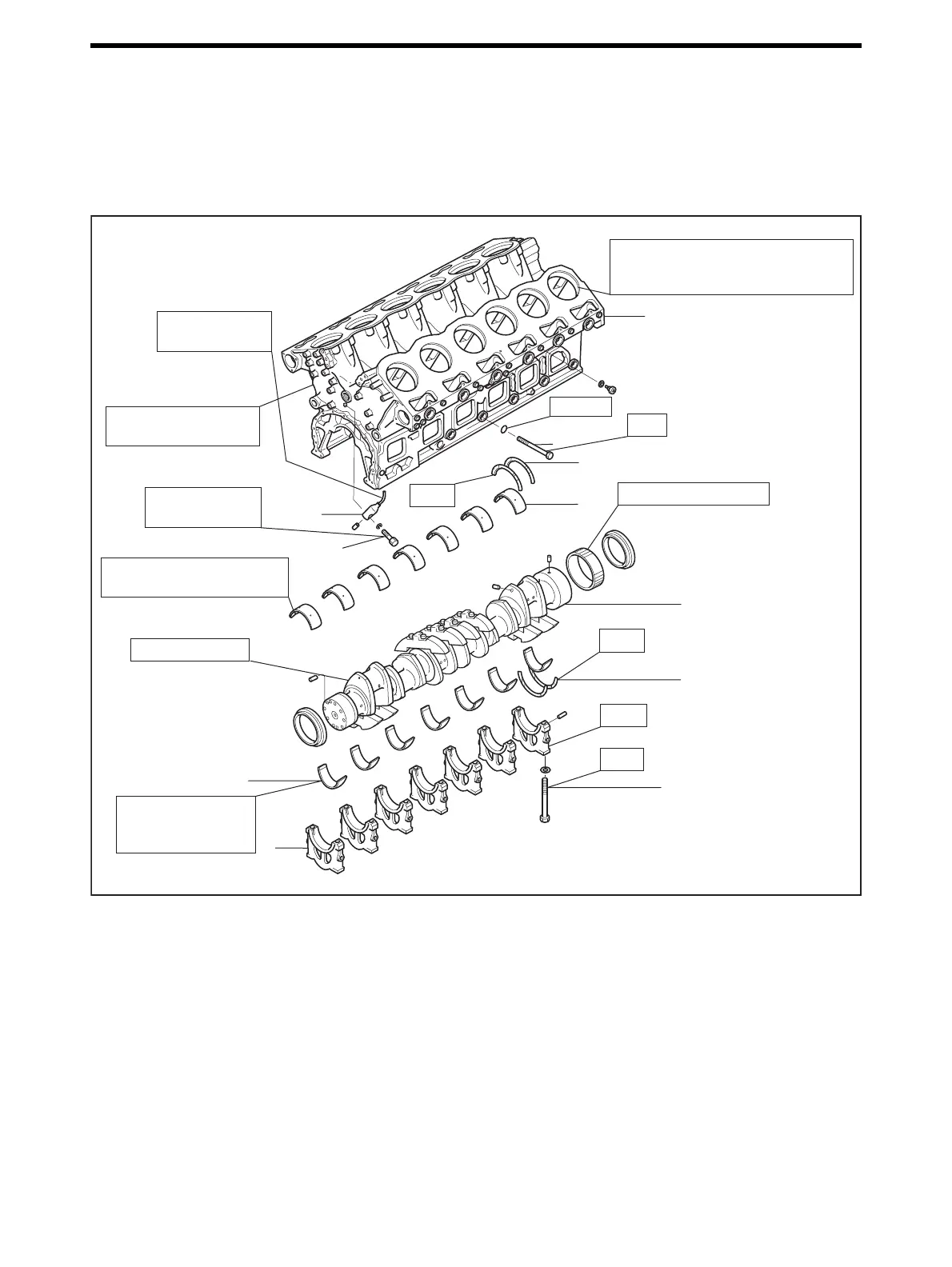

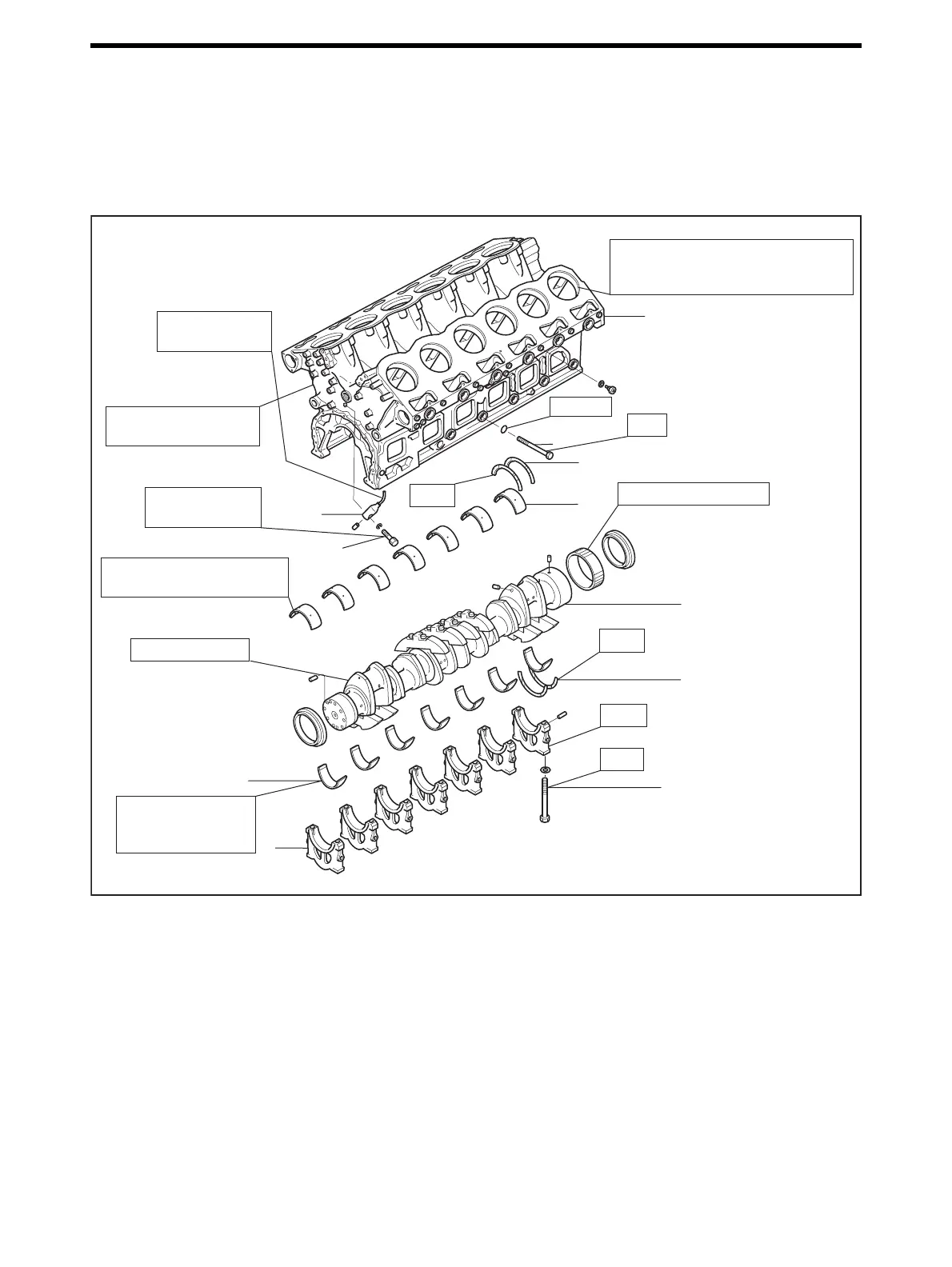

5. Crankcase, Crankshaft and Main Bearing - Disassemble and Inspect

Understanding of the current engine condition before disassembling is very important to know the cause of trouble and do the

efficient work.

Depending on the maintenance work or purpose, it is desirable to inspect some of the following items before proceeding with

any job.

Crankshaft End Play - Measure

Crankcase, Crankshaft and Main Bearing - Disassemble and Inspect

11

10

8

7

6

5

4

3

2

1

9

Scale deposit, flaw,

crack, oil hole clogging

Inner and outer peripheral

face flaw, corrosion, flaking

Wear, flaw, crack

Inner and outer

peripheral face flaw,

corrosion, flaking

Flaw

Peeling, wear, contact

Wear

Valve operation,

oil hole clogging

Local contact, crack on counterbore,

fretting/corrosion on fitting bore of

cylinder liner

Crack

Wear

Replace

Flaw

Oil jet pipe bend,

deformation

Disassembling Sequence

1 Main bearing cap bolt

2 Side bolt

3 Main bearing cap

4 Lower main bearing

5 Lower thrust plate

6 Crankshaft (Approx. 300 kg [661 lb.])

7 Upper main bearing

8 Upper thrust plate

9 Check valve

10 Piston cooling nozzle

11 Crankcase (Approx. 1010 kg [2227 lb.])

Loading...

Loading...