4-4

Chapter 4 OVERHAUL INSTRUCTIONS

2. Compression Pressure - Measure

(1) Remove the injection nozzle from the cylinder head

where the compression pressure is to be measured.

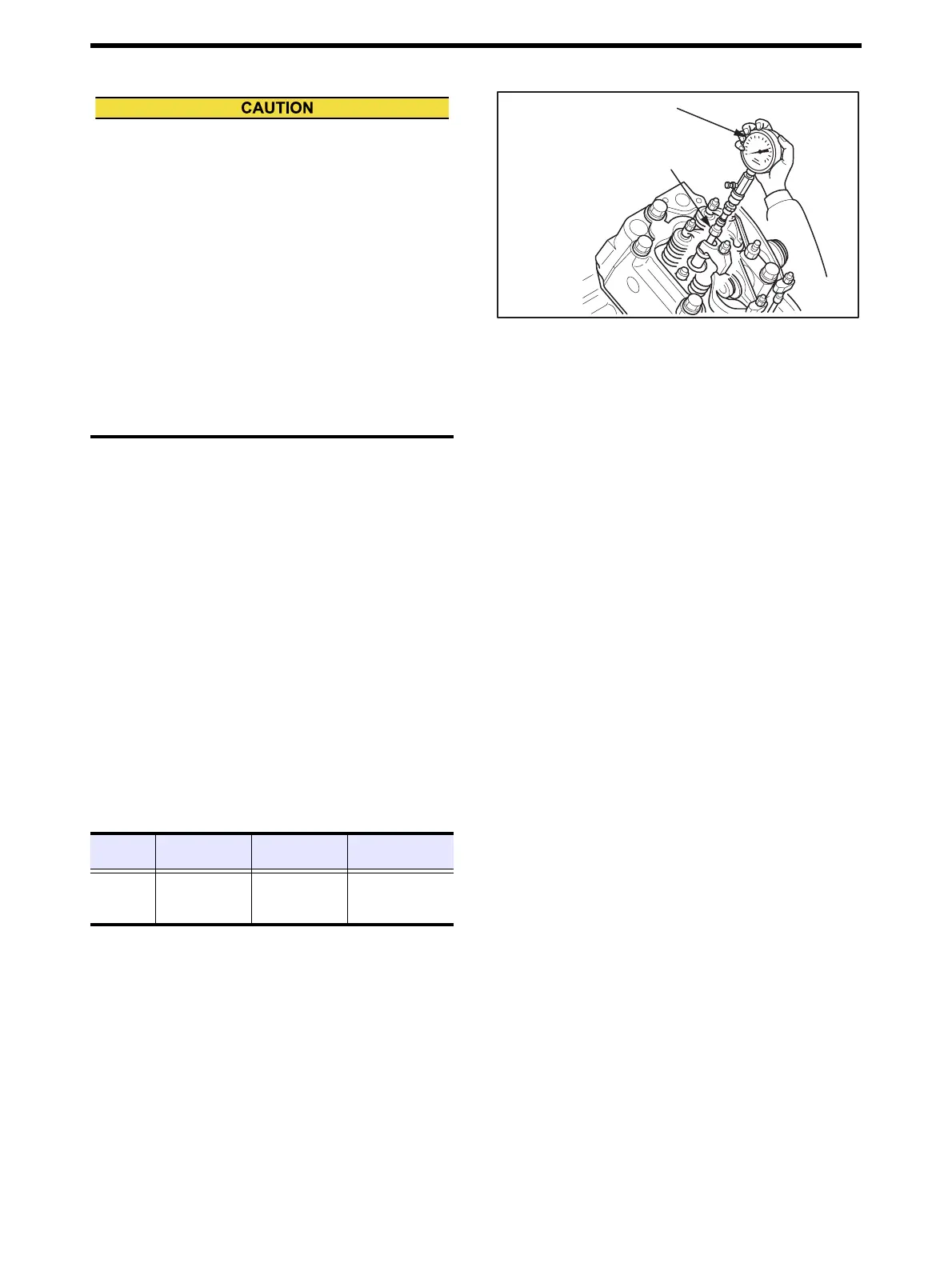

(2) Attach the compression gauge adapter to the fuel injec-

tion nozzle hole and connect the compression gauge.

(3) Place the fuel injection pump rack at the no-injection

position (rack "0" position), and crank the engine with

the starter.

Read the engine speed and compression pressure while

the engine is running at a stable speed.

Note: Ensure the battery being fully charged when cranking

the engine with the starter.

If the battery voltage is low, the proper compression

pressure can not be measured because of a low crank-

ing speed.

(4) If the measured value exceeds the limit, overhaul the

engine.

Compression Pressure - Measure

(a) Be sure to measure the compression pressure of

all cylinders. It is not a clever way to measure

the compression pressure of only two or three

cylinders, and assume the compression pres-

sure of all other cylinders. Cylinders are all inde-

pendent.

(b) Also be sure to check the engine speed when

measuring the compression pressure, as the

compression pressure varies depending on the

engine speed.

(c) It is important to measure the compression pres-

sure at regular intervals, and know the change of

the pressure.

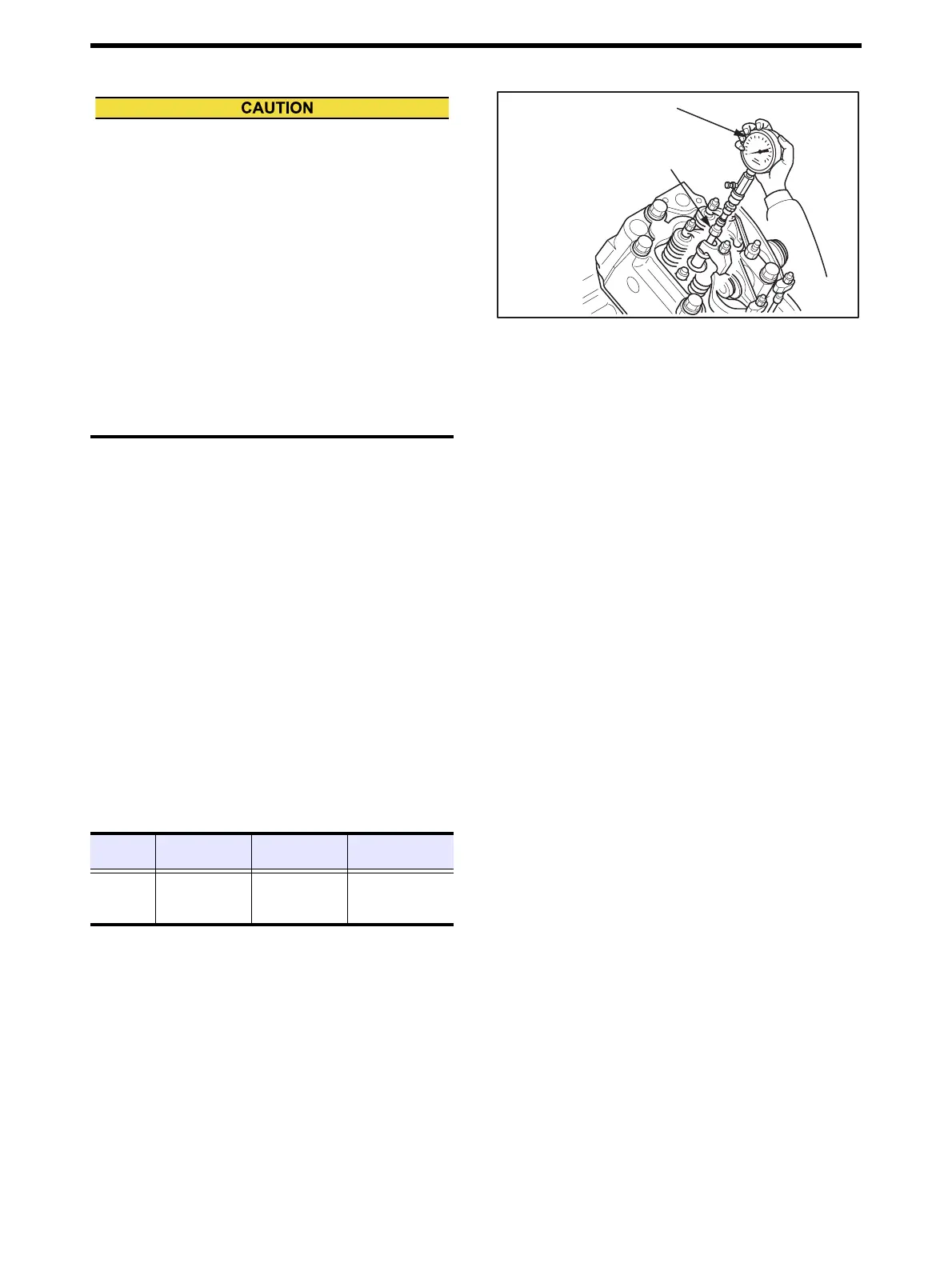

Item Standard value Limit value

Basic

Rotation speed

Compres-

sion pres-

sure

2.35 MPa

{24 kgf/cm

2

} or

more

1.86 MPa

{300 kgf/cm

2

}

[4267 psi]

120 to 200 min

-1

Compression gauge

P/N:33A91-01700

Gauge adapter

P/N:36291-02200

Loading...

Loading...