7-33

Chapter 7 ASSEMBLY OF BASIC ENGINE

5.13 Valve Clearance - Check and Adjust

Adjust the valve clearance when the engine is cold.

Note:(a) The inlet valves are on the left side and exhaust

valves are on the right when the cylinder head is

viewed from camshaft side.

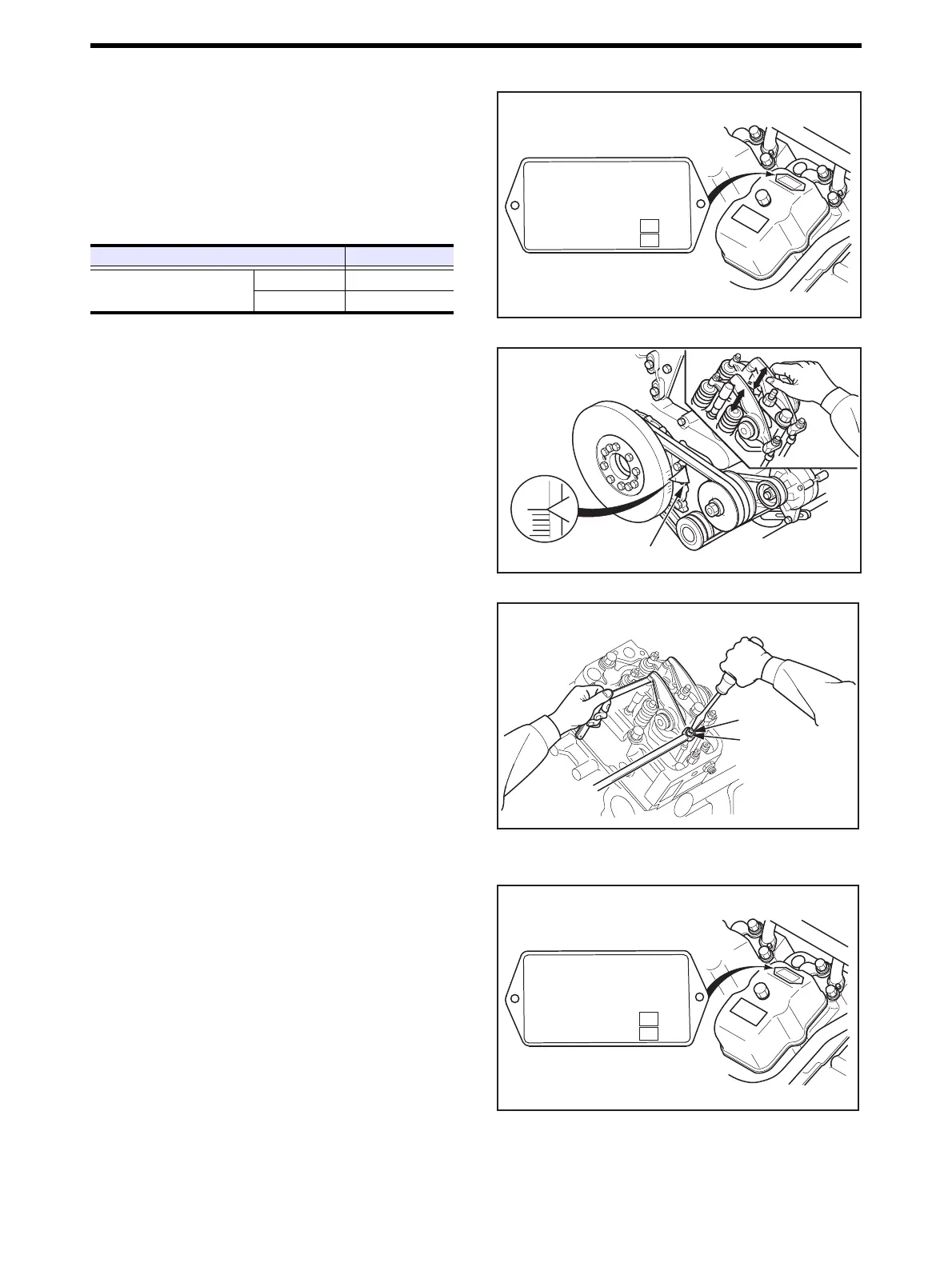

(b) The valve clearance standard values are shown on

the caution plate on the No. 1 cylinder rocker cover.

(1) Adjust the valve clearance in the firing order at TDC of

compression stroke by turning crankshaft in the normal

direction.

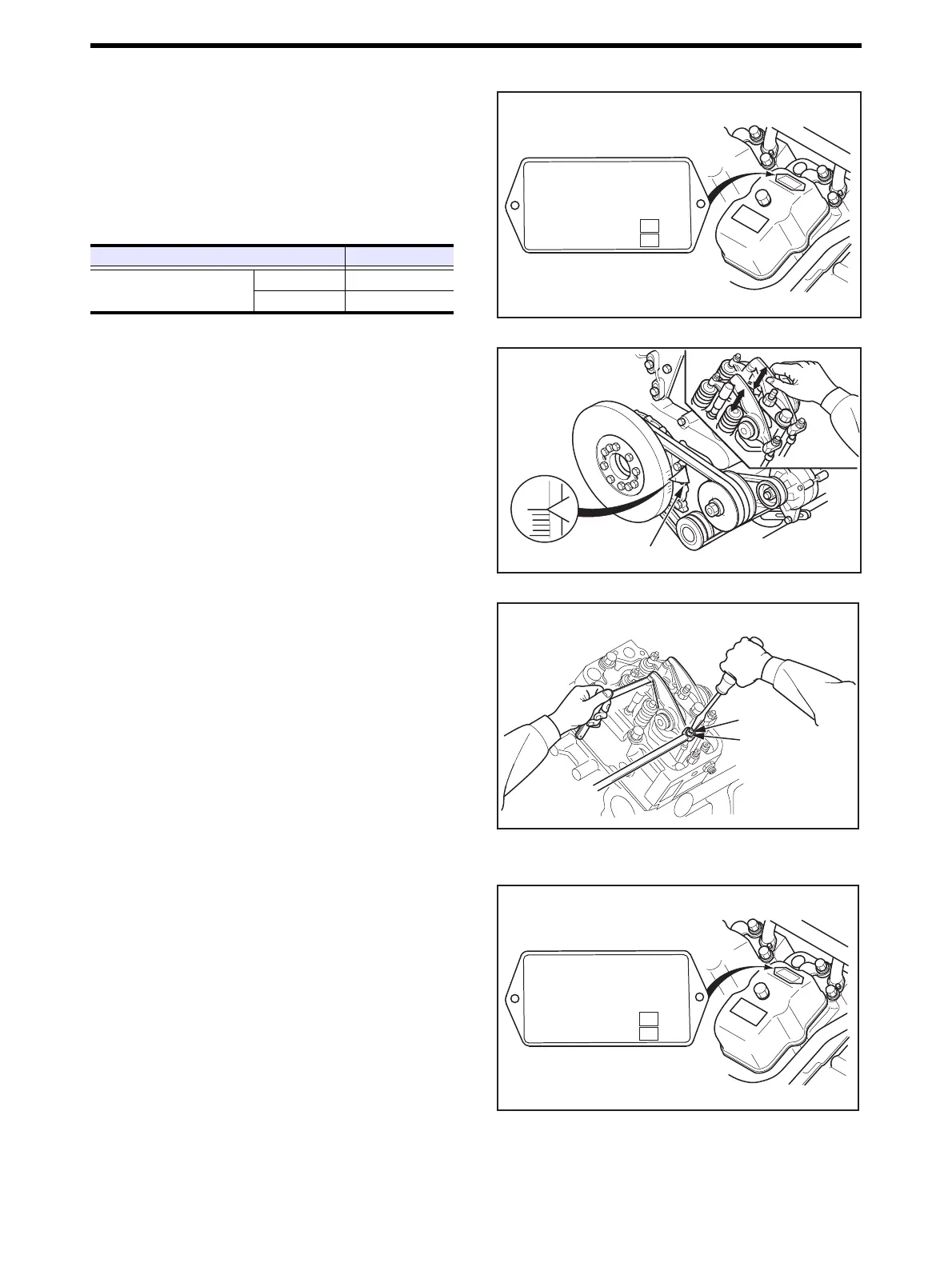

(2) On each cylinder, the piston is at the top dead center on

compression stroke, when corresponding cylinder num-

ber stamped on damper is aligned with pointer, and

inlet valves and exhaust valves are not pushed with

push rod.

(3) Insert a thickness gauge between rocker arm and bridge

cap to measure the clearance. Tighten or loosen the

screw to adjust the clearance where the movement of

thickness gauge becomes slightly restricted.

(4) After the adjustment tighten the lock nut firmly to the

specified torque. Then, check the clearance again.

Valve Clearance Label - Location

No. 1 Cylinder Compression Top Dead Center - Check

Valve Clearance - Adjust

5.14 Fuel Injection Timing - Check and Adjust

5.14.1 Specified Value of Fuel Injection Timing - Check

The fuel injection timing varies depending on the engine

output, speed and specifications. Be sure to check the plate

on the No. 1 rocker cover for the fuel injection timing.

Specified Value of Fuel Injection Timing - Check

Item Standard value

Valve clearance

Inlet 0.4 mm [0.016 in.]

Exhaust 0.5 mm [0.019 in.]

8#.8'%.'#4#0%'%1.&

+0.'6

(+4+0) 14&'4

(7'.+0,'%6+106+/+0)

':*#756

OO

OO

$6&%

q

%1041&4#0-

・

Pointer

Cylinder firing order:

1-12-5-8-3-10-6-7-2-11-4-9

Screw

Lock nut

64 ± 6.4 N·m

{6.5 ± 0.65 kgf·m}

[47 ± 4.7 lbf·ft]

8#.8'%.'#4#0%'%1.&

+0.'6

(+4+0) 14&'4

(7'.+0,'%6+106+/+0)

':*#756

OO

OO

$6&%

q

%1041&4#0-

Loading...

Loading...