5-8

Chapter 5 DISASSEMBLY OF BASIC ENGINE

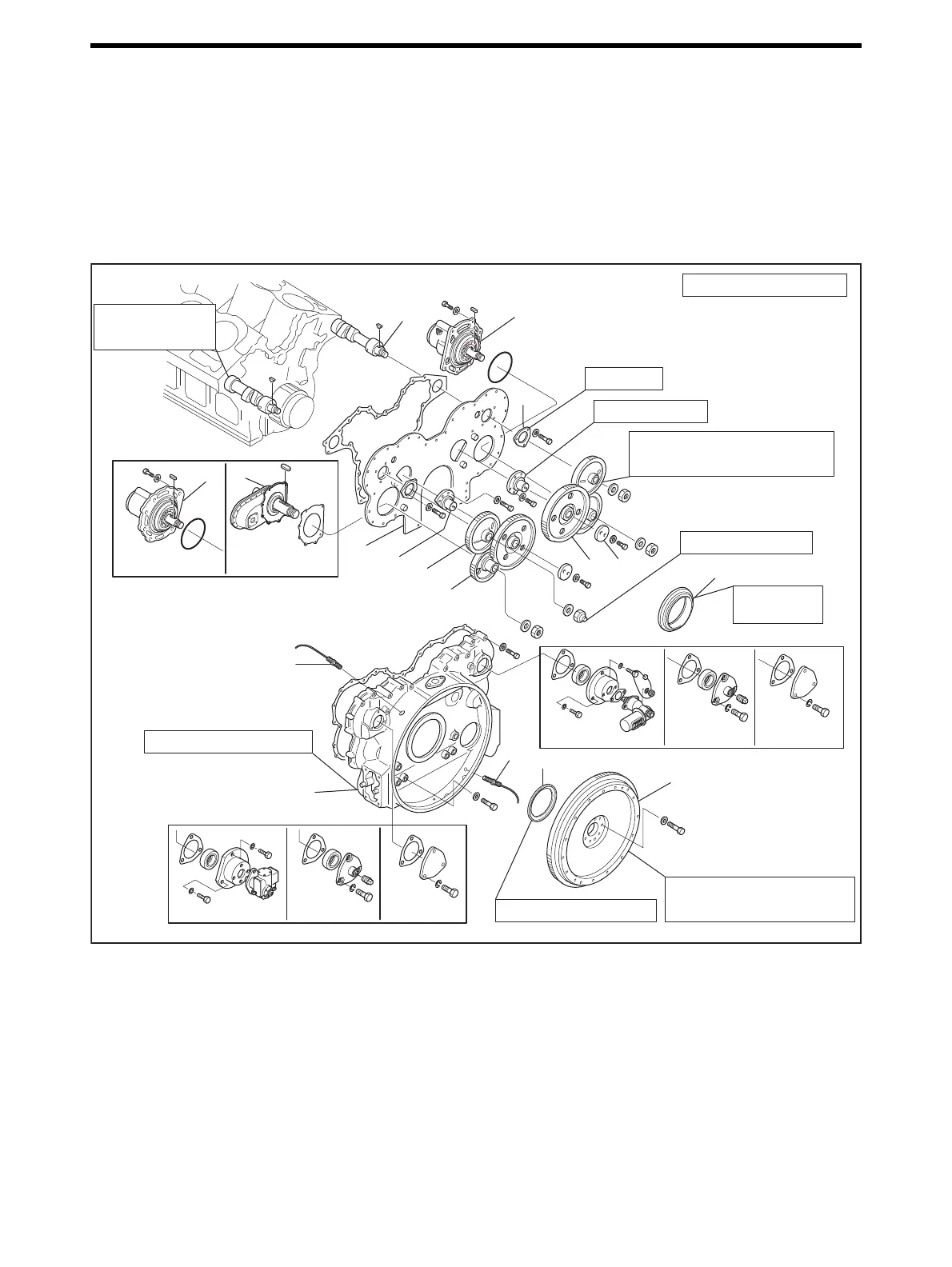

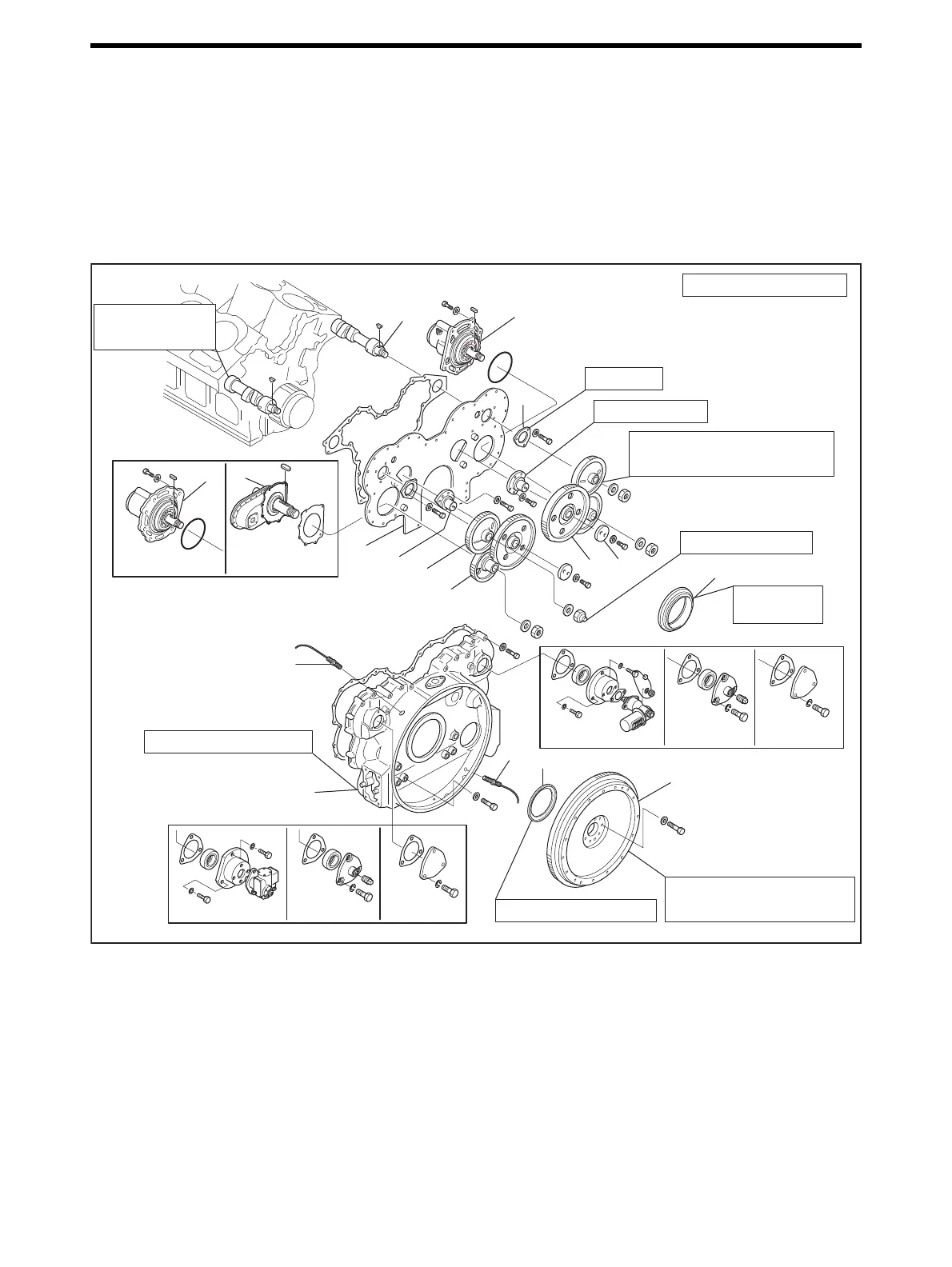

2. Rear Mechanism - Disassemble and Inspect

Understanding of the current engine condition before disassembling is very important to know the cause of trouble and do the

efficient work.

Depending on the maintenance work or purpose, it is desirable to inspect some of the following items before proceeding with

any job.

Flywheel Face and Radial Runout - Measure

Timing Gear Backlash - Measure

Idler Gear and Camshaft End Play - Measure

Rear Mechanism - Disassemble and Inspect

Replace: Gasket, O-ring

Flaw, wear

Oil hole clogging

Flaking, wear,

key way deformation and wear

Groove crack, wear

Crack, dowel hole defect

Crack, dowel hole defect,

flaw on gear, abnormal wear

Flaw, wear,

key groove defect

Wear, flaw,

deterioration

Electronic

governor spec

Oil pressure

governor spec

Hour meter spec

Tachometer spec

Non-

attachment spec

Non-

attachment spec

Non-

attachment spec

Non-

attachment spec

Wear, flaw, deterioration

13

14

11

12

5

3

8

9

9

9

10

2

1

1

4

6

7

Disassembling Sequence

1 Pick up (electronic governor spec)

2 Flywheel (Approx. 83 kg [183 lb])

3 Timing gear case (Approx. 43 kg [95 lb])

4 Oil seal

5 Oil seal slinger

6 Thrust plate

7 Idler gear

8 Fuel injection pump gear

9 Accessory drive (electronic governor spec)

Governor drive (Oil pressure governor spec)

(Refer to the chapter "FUEL SYSTEM" for disassembly, in-

spection and assembly.)

10 Camshaft gear

11 Thrust plate

12 Camshaft (Approx. 25 kg [55 lb.])

13 Idler shaft

14 Rear plate (Approx. 21 kg [46 lb])

Loading...

Loading...