13-3

Chapter 13 ADJUSTMENT AND OPERATION

Chapter 13 ADJUSTMENT AND OPERATION

1. Engine - Adjust

1.1 Valve Bridge and Adjusting Screw - Check

Check the adjustment of valve bridge and adjusting screw.If

it is not adjusted, adjust it to the standard value.

For the adjusting procedure, refer to "Valve Bridge and

Adjusting Screw - Adjust" of "ASSEMBLY OF BASIC

ENGINE."

1.2 Valve Clearance - Check

Check the valve clearance.

If it is not adjusted, adjust it to the standard value.

For the adjusting procedures, refer to "Valve Clearance -

Inspect and Adjust" of "ASSEMBLY OF BASIC

ENGINE. "

1.3 Fuel Injection Timing - Check

Check the fuel injection timing.

If it is not adjusted, adjust the timing to the specified value.

For the adjusting procedures, refer to "Fuel Injection Timing

- Check and Adjust" of "ASSEMBLY OF BASIC

ENGINE. "

1.4 Fuel System - Bleed Air

To bleed air from fuel system, start air bleeding at the place

nearest to fuel tank, from fuel filter to injection pump, while

feeding fuel with priming pump.

Priming Pump - Operate

1.4.1 Fuel Filter (Wire Mesh Element Spec) - Bleed

air

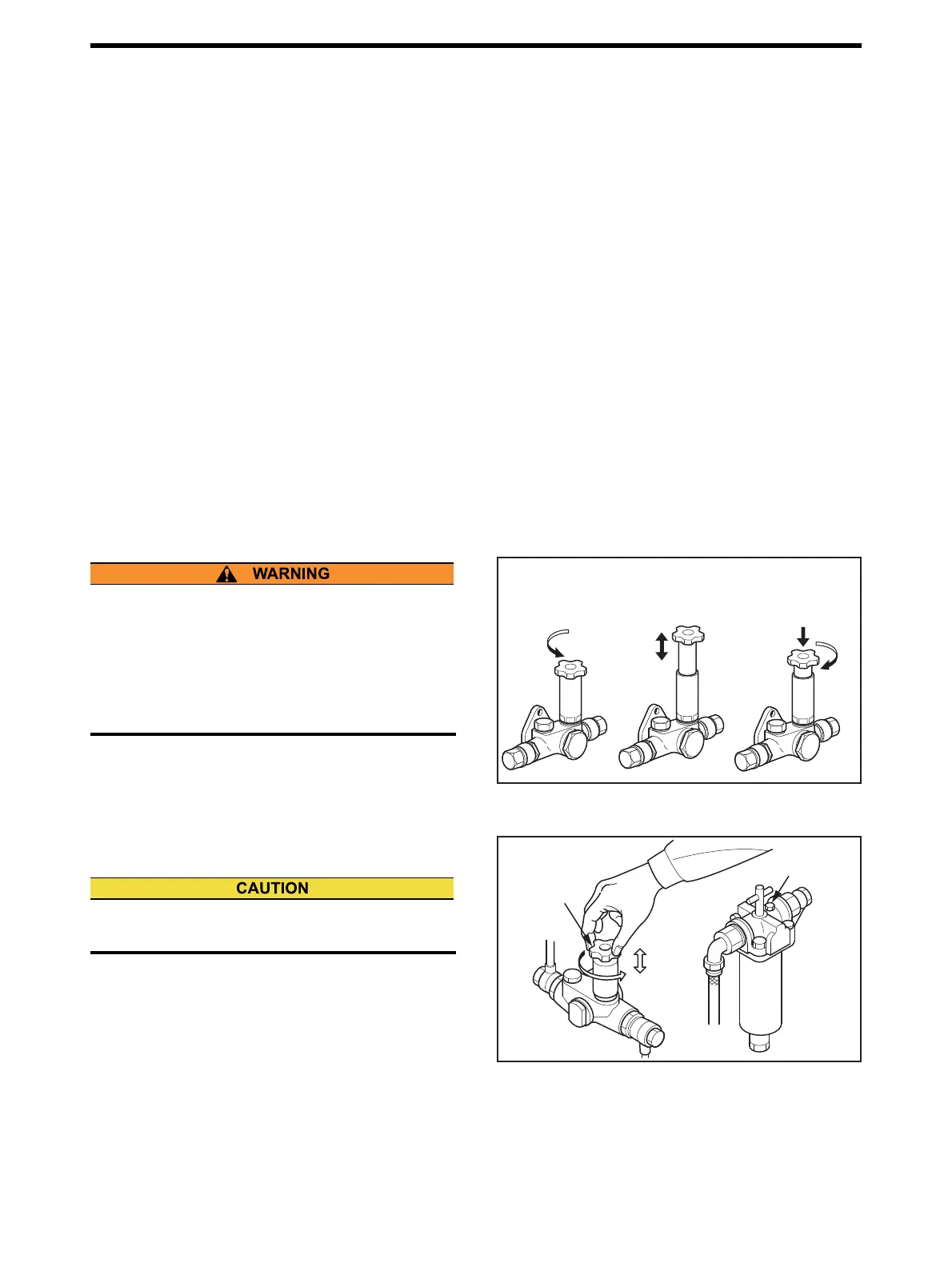

(1) Loosen the air vent plug of fuel filter by approx 1.5

turns.

(2) Feed fuel by moving the priming pump up and down.

(3) When fuel flowing from vent holes no longer contains

air bubbles, tighten the air vent plugs to the specified

torque.

Fuel Filter (Wire Mesh Element Spec) - Bleed air

(a) Thoroughly wipe off fuel spilled out of air vent plug

to prevent a fire.

(b) After air bleeding, ensure the lock of priming pump

cap.If locking is insufficient, it could cause damage

to the priming pump and result in fuel leak and a

fire.

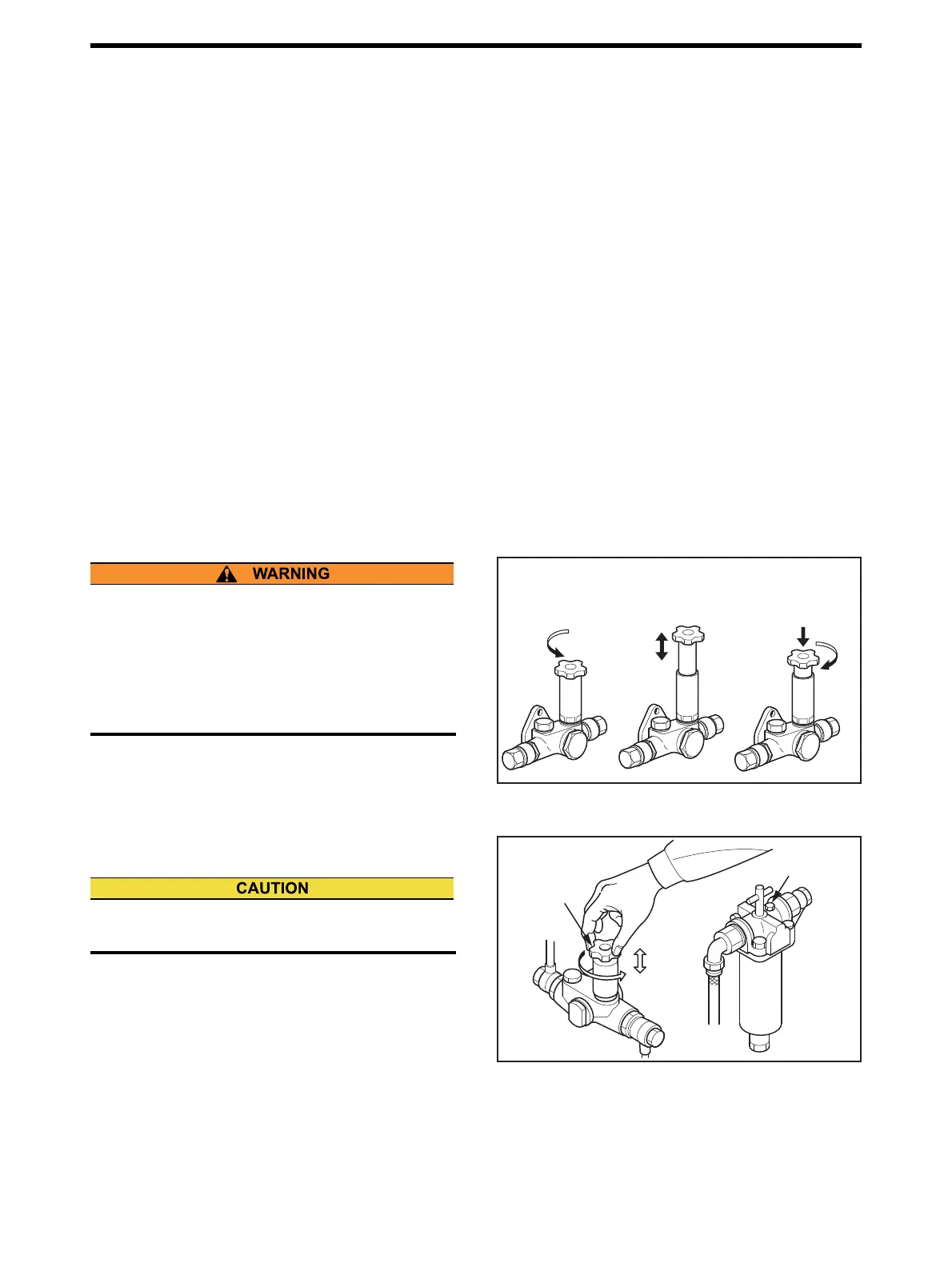

[Unlock] [Prime] [Lock]

Turn counterclockwise

Move cap

up and down

Turn clockwise

while pressing

If the air vent plugs, threads of bracket or sealing

washers are damaged, replace them with new ones.

Air vent plug

Priming pump

cap

Loading...

Loading...