10-24

Chapter 10 COOLING SYSTEM

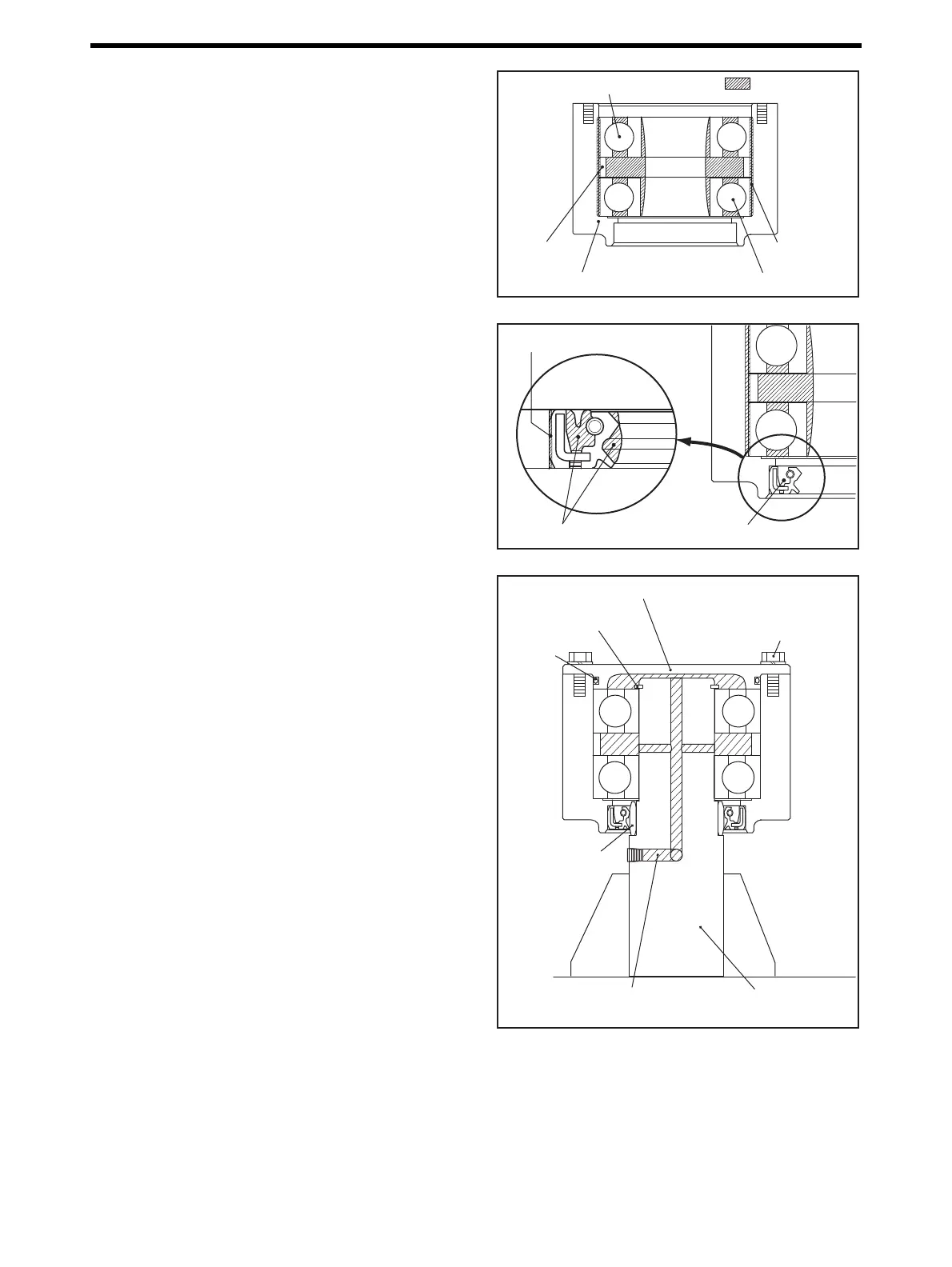

2.4.2 Tension pulley - Assemble

(1) Before pressing-fit the tension pulley, apply grease to

both ball of ball bearing and ball-cage.

(2) Apply grease to the inside tension pulley, and press-fit

the lower ball bearing.

(3) Install the plain washer, and press-fit the upper ball

bearing.

Note: Load the outer ring when pressing-fit the ball bearing.

Ball Bearing - Press-fit

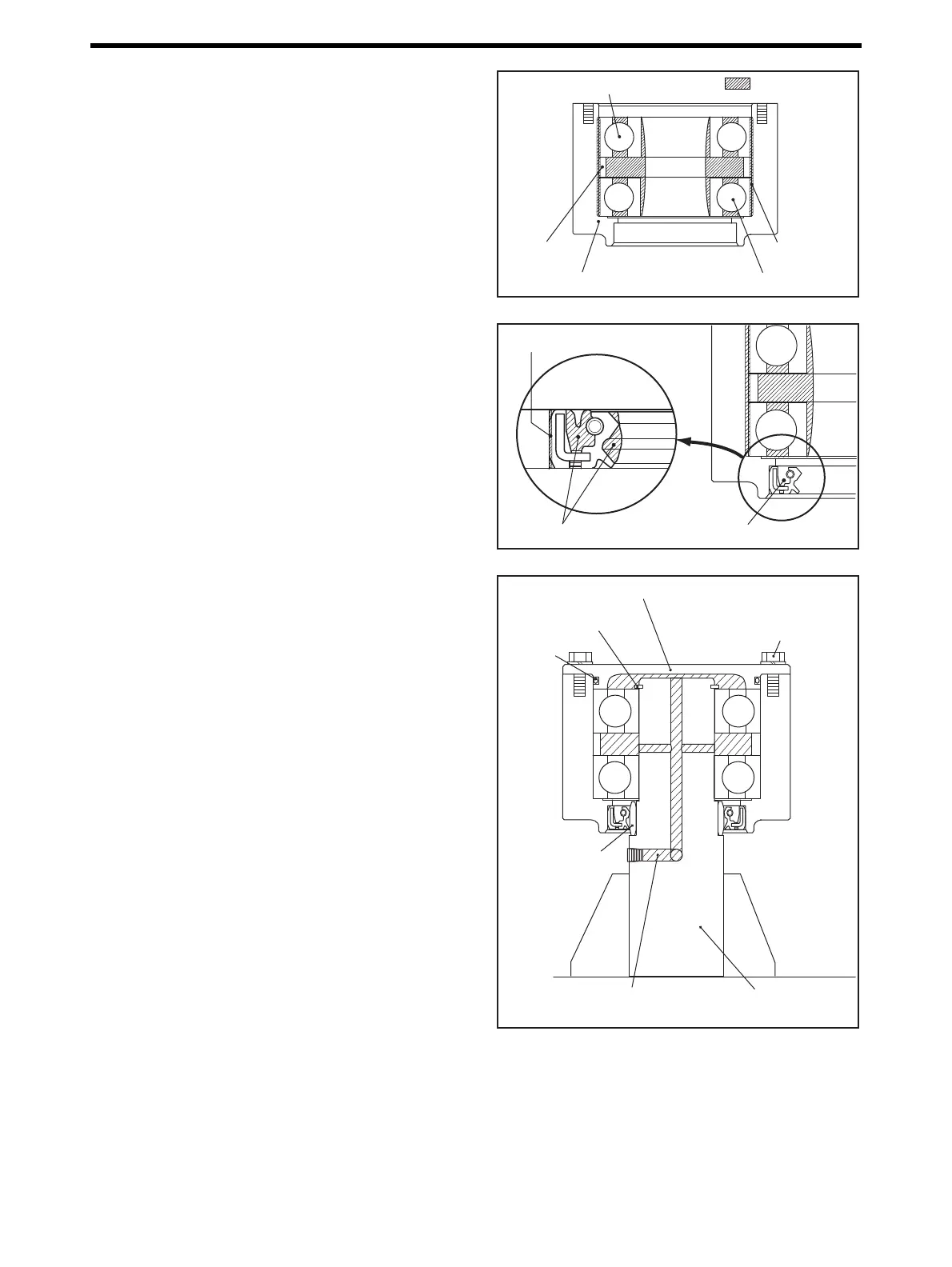

(4) Apply sealant (ThreeBond 1215) to the inside surface

of the oil seal installation part of tension pulley.

(5) Apply grease to the oil seal lip and dust seal lip, and

press-fit the oil seal to the tension pulley.

Oil Seal - Install

(6) Press-fit the oil seal sleeve to the tension shaft.

(7) Press-fit the tension pulley that installed the ball bear-

ing and oil seal to the tension shaft.

(8) Fix the tension shaft and ball bearing with snap ring.

Note: Check that the clearance to the shaft after installing the

snap ring.

(9) Install the bearing cover that mounted O-ring, and

tighten the bolt to specified torque.

(10)Remove the taper plug, and fill the specified grease to

the oil hole of tension shaft.

Tension pulley - Insert

Apply grease

Tension pulley

Ball bearing

Ball bearing

Pulley inner

face

Tension

spacer

Oil seal

Fill grease

Apply sealant

30 ± 3.0 N·m

{3.0 ± 0.3 kgf·m}

[22.1 ± 2.21 lbf·ft]

P/N:37594-01600

Inject grease 50 cm

3

Snap ring

O-ring

Bearing cover

Oil seal sleeve

Tension shaft

Loading...

Loading...