7-10

Chapter 7 ASSEMBLY OF BASIC ENGINE

2.3 Cylinder Liner - Install

(1) Install the O-rings to the cylinder liner.

(2) Insert the shim to the cylinder which needs the adjust-

ment of cylinder liner flange protrusion.

(3) Apply engine oil to the O-ring fitting bore in Crankcase

and cylinder liner O-ring sliding surfaces.

Cylinder Liner O-Rings - Install

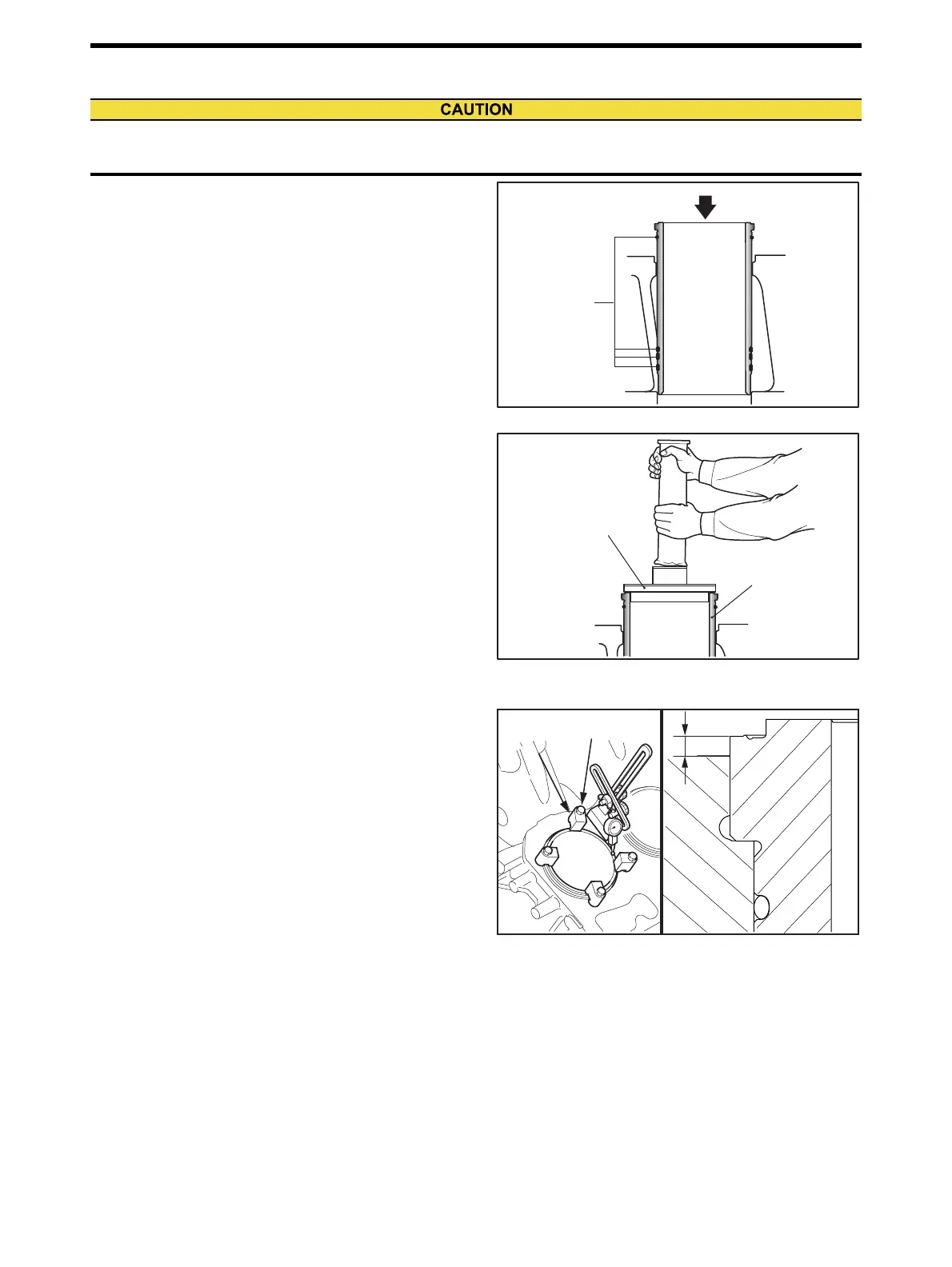

(4) Slowly insert the cylinder liner into the bore in the

crankcase.With a correct cylinder liner installer, lightly

tap the cylinder liner until its flange contacts snugly on

the seating surface of the crankcase.Then, lightly tap

the liner several times to verify the stable seating.

Note: To verify the correct O-rings installation, measure the

roundness of inside diameter of the cylinder liner (es-

pecially O-ring installing position.)

Cylinder Liner - Install

2.4 Cylinder Liner Flange Protrusion - Measure (When Cylinder Liner Installed)

(1) Remove dust and dirt from the crankcase top face and

the cylinder liner top end face to measure.

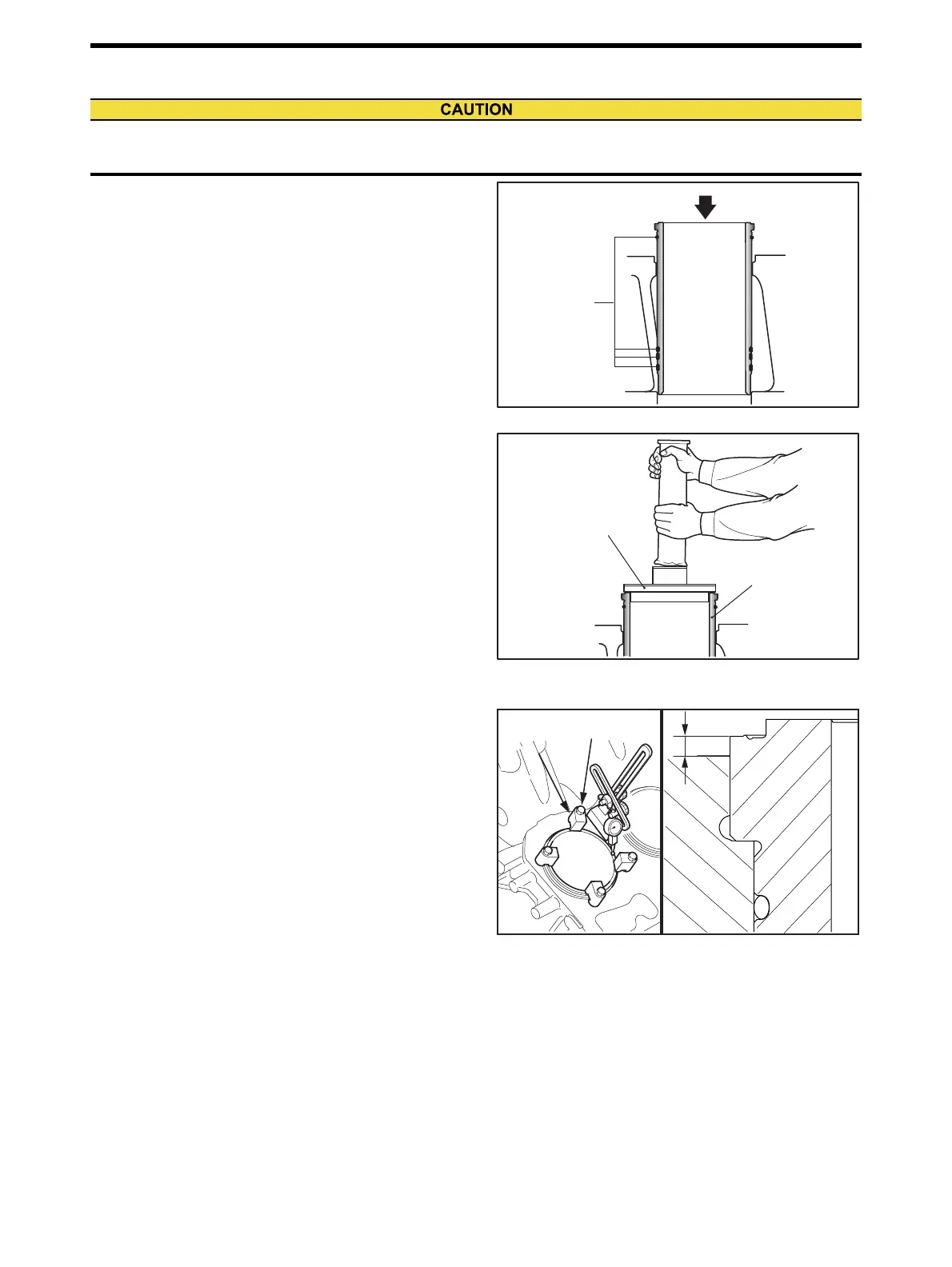

(2) Place the liner pusher on equally spaced 4 positions of

the cylinder liner upper rim and tighten the pusher bolts

evenly to make a close contact of the cylinder liner and

the crankcase.

(3) Apply a dial gauge probe to the top face of the crank-

case, and the dial gauge to zero.

(4) Slide the probe to measure the flange protrusion at four

places on the top of the cylinder liner, and calculate the

mean value.

(5) If the mean value of the protrusion is smaller than the

standard, insert a shim under the cylinder liner flange.

For shim and standard value, refer to "Cylinder Liner

Flange Protrusion - Calculate (When Cylinder Liner

Not Installed)" of "ASSEMBLY OF BASIC ENGINE."

Cylinder Liner Flange Protrusion - Measure

Apply engine oil to the O-ring sliding surfaces to prevent O-rings from twisting.

Do not apply engine oil to the O-ring grooves on cylinder liner.

Application of

engine oil

Cylinder liner

Installer

P/N:32591-01800

Bolt

Cylinder liner flange

protrusion

Liner pusher

Cylinder liner flange

protrusion

Liner pusher

Loading...

Loading...