11-15

Chapter 11 INLET AND EXHAUST SYSTEMS

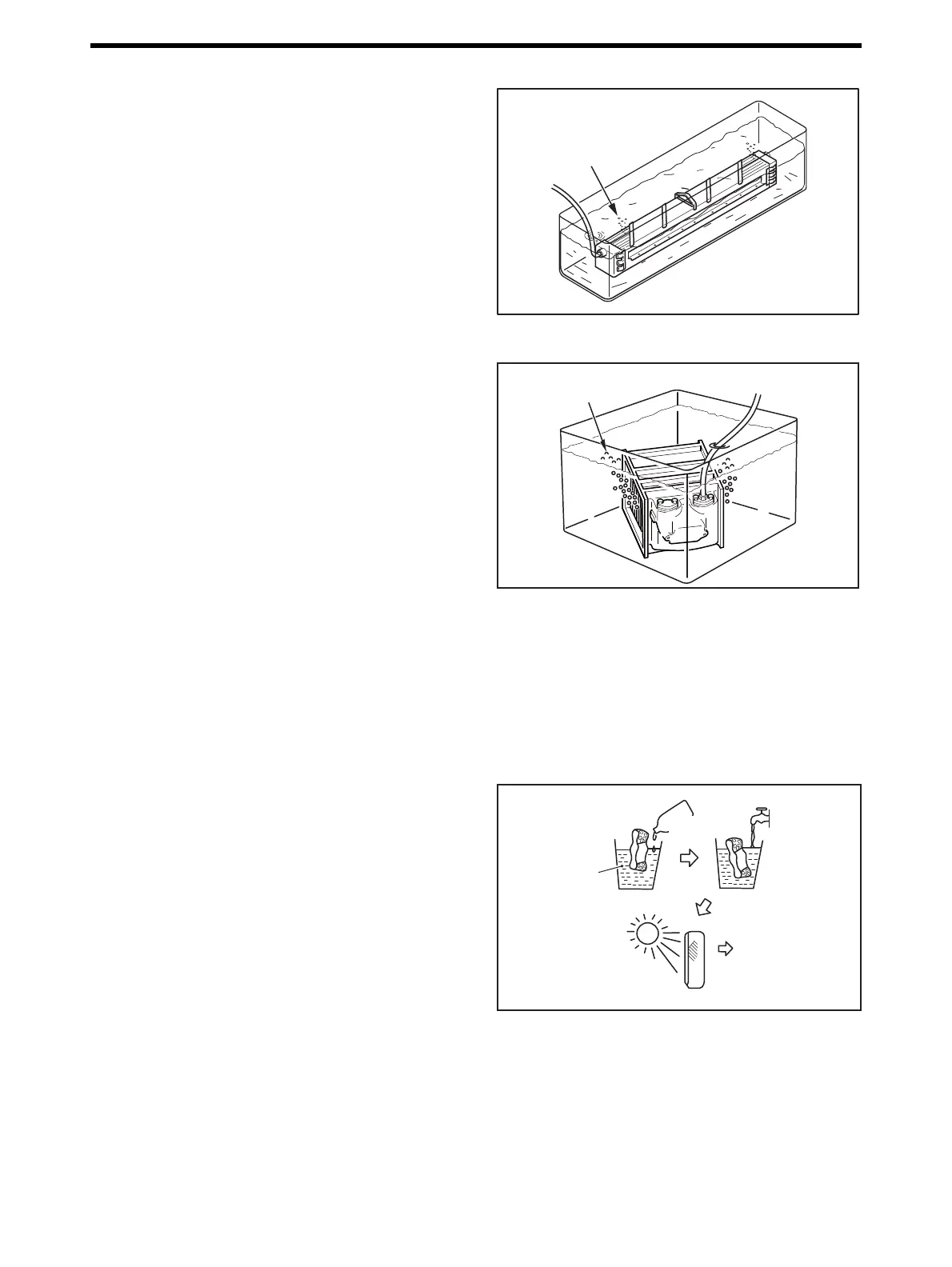

2.1.3 Air cooler - Inspect for Leakage

Immerse the air cooler in water. In this condition, blow

compressed air (at a pressure of 0.39 MPa {4 kgf/cm

2

} [57

psi]) to the coolant passage to check for air leakage.

PTA, PTA2, PTAW, PTK, MPTA spec

Air cooler - Check for Leakage

MTK and MPTK Spec Air cooler - Check for Leakage

2.1.4 Air cooler - Assemble

To assemble, follow the disassembly sequence in reverse.

Seal the clearance between the PTA, PTA2, PTAW, PTK,

and MPTA spec air cooler element and plate with KE45-W

(Shin-Etsu Chemical Co., ltd.) or equivalent silicone seal-

ant.

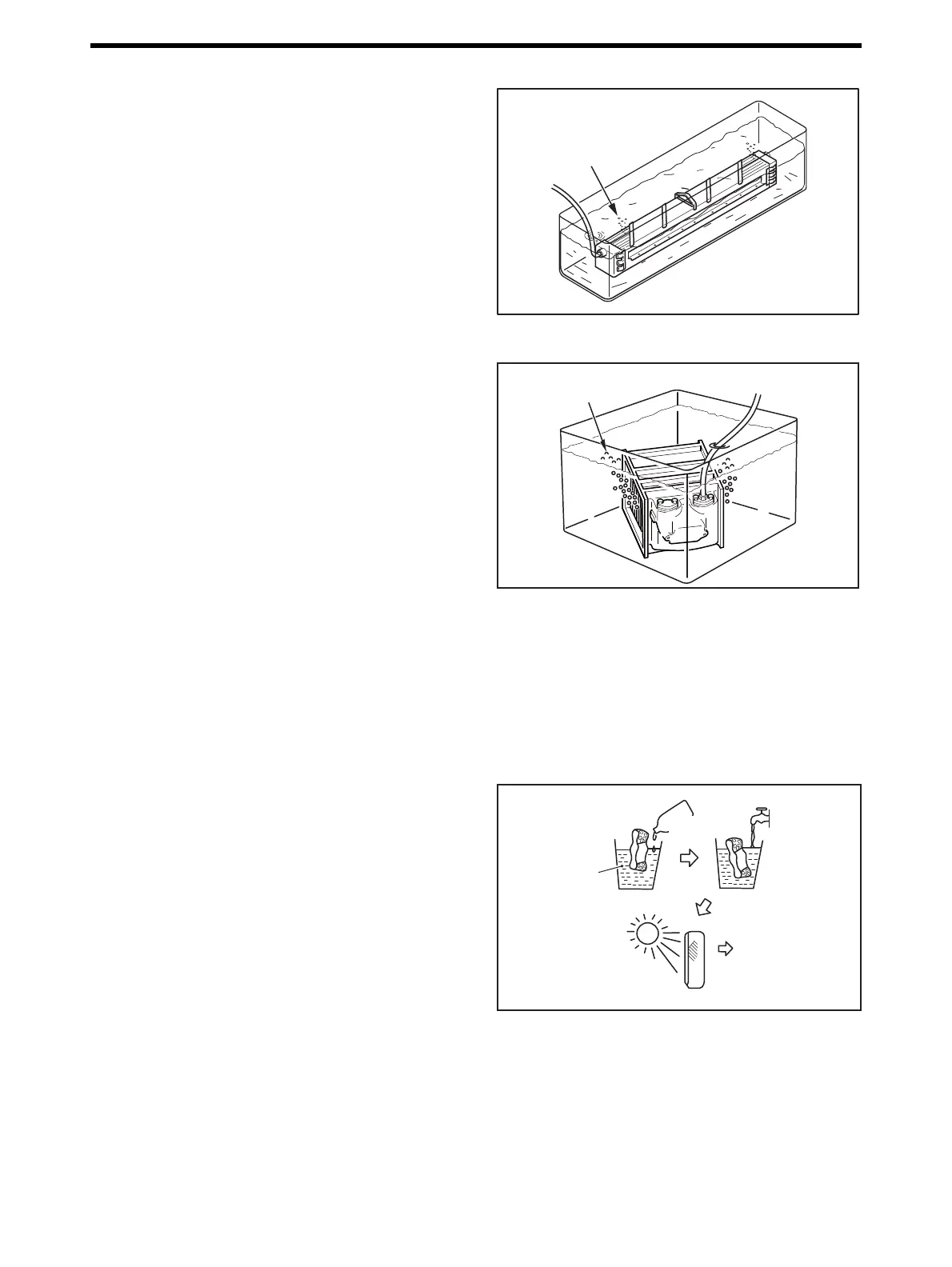

2.2 Pre-cleaner - Clean

(1) Remove the pre-cleaner from the silencer, and hand-

wash the pre-cleaner using neutral detergent.

(2) Rinse with fresh water.

(3) Dry it thoroughly, and install it to the silencer.

Note: If the pre-cleaner is damaged or torn, replace it with a

new one.

Pre-cleaner - Clean

Air leakage

Air leakage

(Wash)

(Rinse)

Water

Install

(Dry)

Mild

detergent

Loading...

Loading...