6-24

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

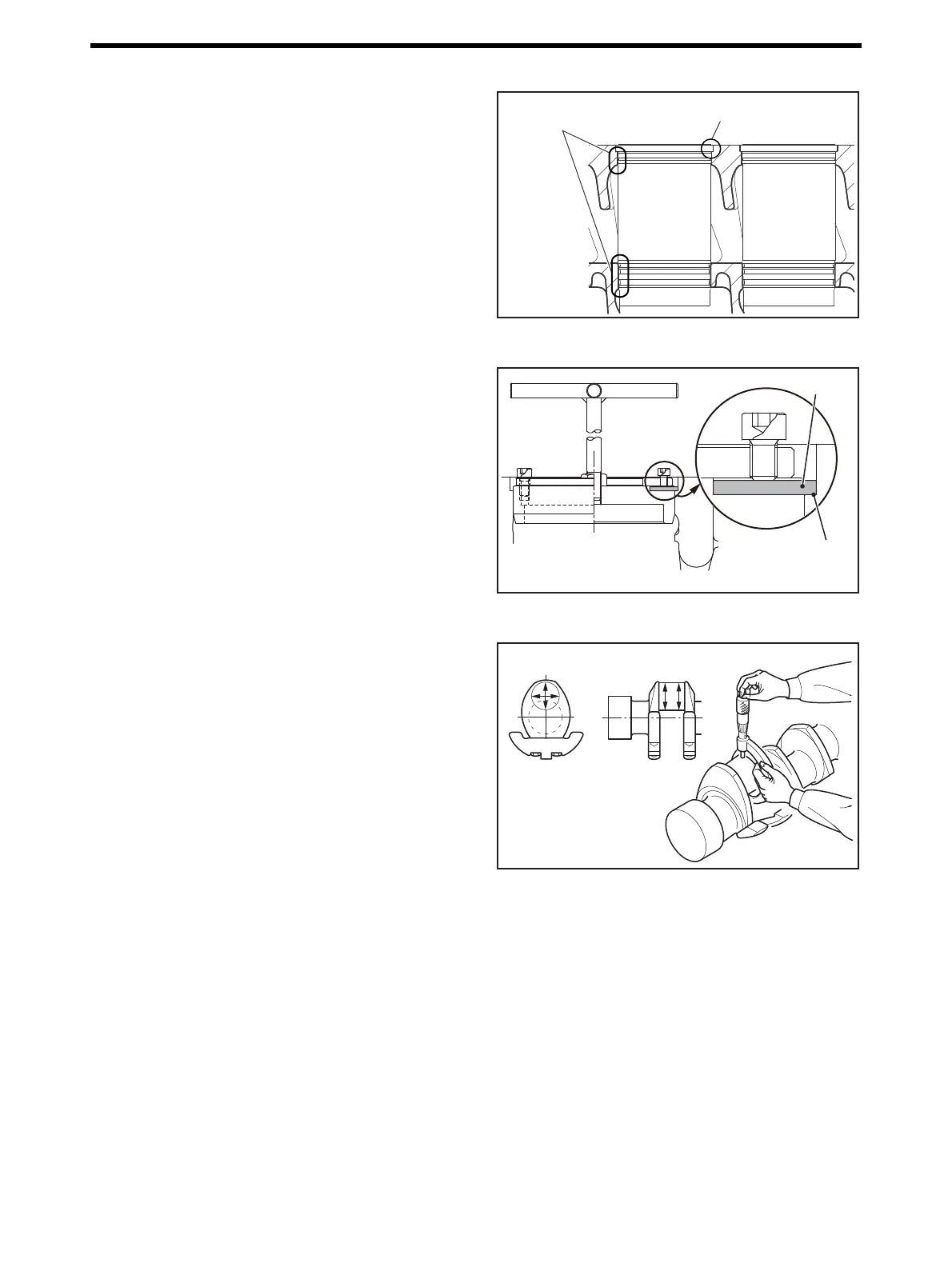

5.3 Cylinder Liner Fitting Bore in Crankcase - Inspect

(1) Inspect the counterbore in crankcase. Check for cracks

in edges, uneven contact between counterbore and bot-

tom face of cylinder liner flange.If any defect is found,

reface the counterbore in crankcase.

(2) Inspect the cylinder liner fitting section in crankcase.

Check for the defects such as fretting and corrosion.

Cylinder Liner Fitting Bore in Crankcase - Inspect

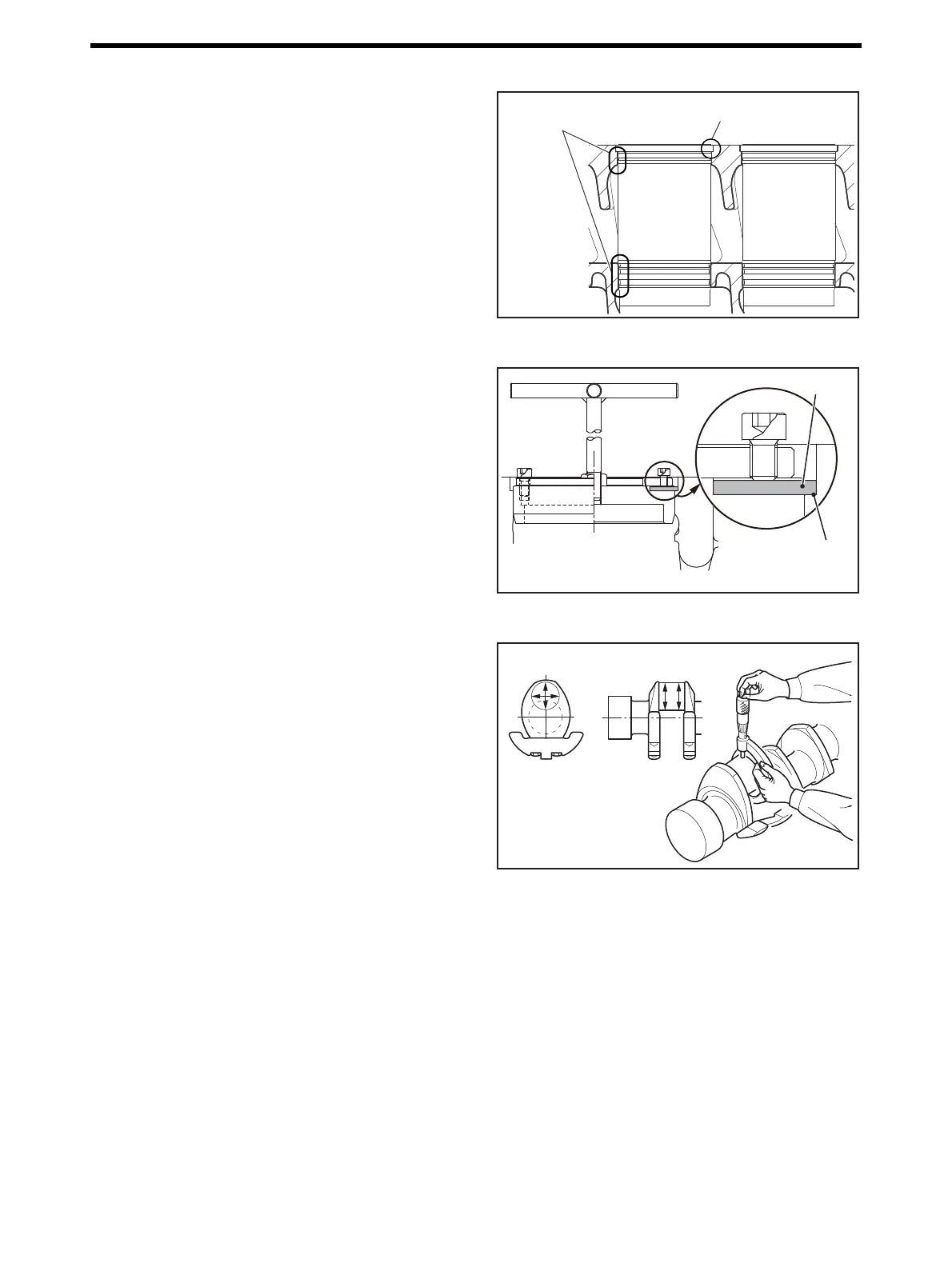

5.4 Counterbore in Crankcase - Repair

If local contact is shown on counterbore in crankcase, grind

and repair.Grind the counterbore with crankcase grinder to

correct the difference in depth at four directions in circum-

ference to be less than 0.05 mm [0.0020 in.]

After the grinding of counterbore in crankcase is completed,

measure the cylinder liner flange protrusion.

Counterbore in Crankcase - Repair

5.5 Crankpin and Journal Outside Diameters - Measure

(1) Measure the outside diameter of crankpins and crank

journals.

If the value exceeds the limit, use the undersize bearing,

and grind the crankshaft to fit the undersize bearing.If

the value exceeds the limit even when the -1.00 mm [-

0.0394 in.] undersize bearing is used, replace the crank-

shaft with a new one.

(2) know the roundness and cylindricity based on measured

values.

Crankpin Outside Diameter - Measure

Fitting bore of cylinder liner

in crankcase

Counterbore in crankcase

Crankcase grinder

P/N:32591-04050

Grinder

Crankcase

counterbore

Measurement

direction

Measurement

point

Loading...

Loading...