10-19

Chapter 10 COOLING SYSTEM

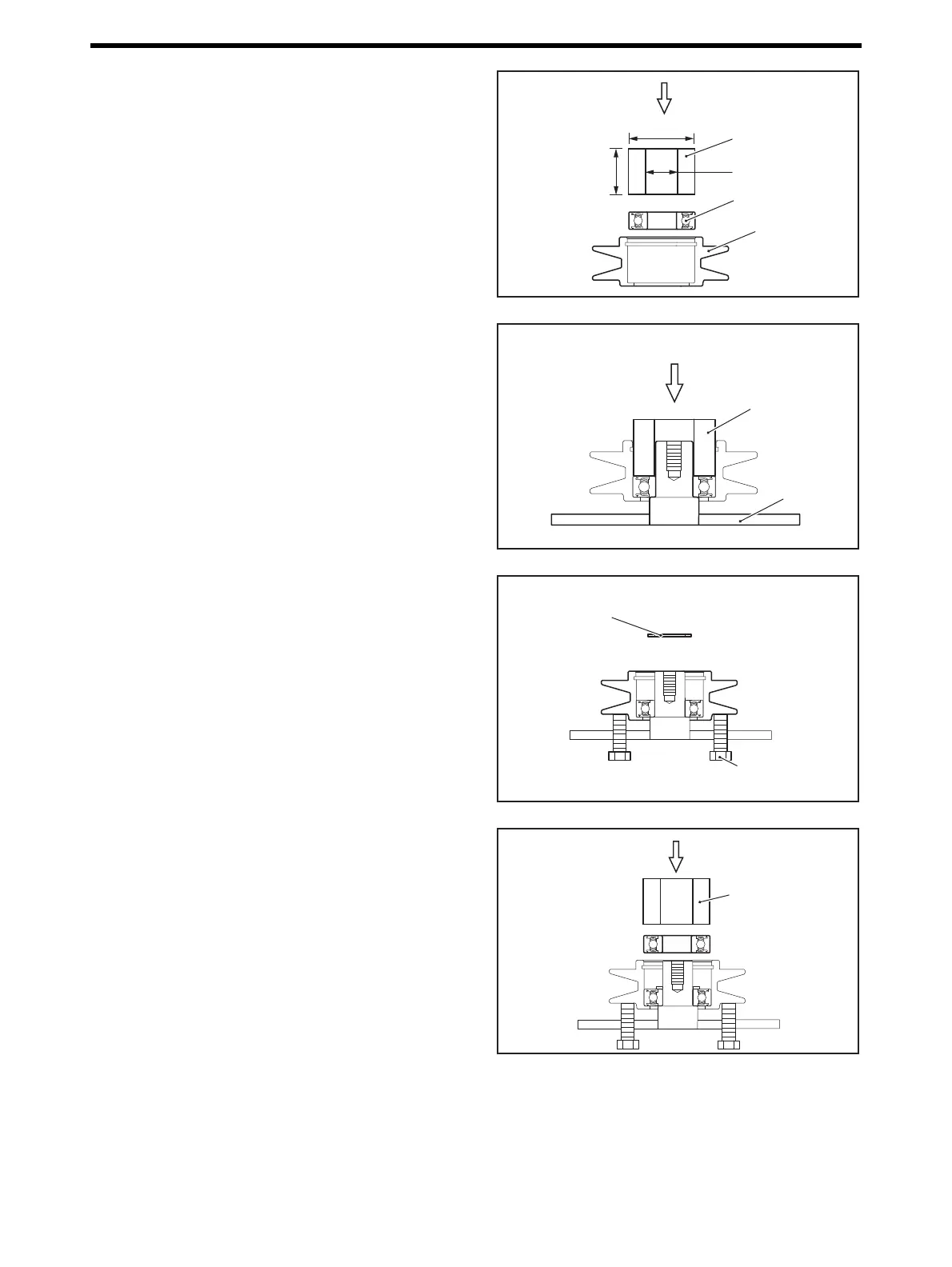

2.2.2 Tension pulley - Assemble

(1) Apply engine oil to the fitting faces of bearing and ten-

sion pulley.

(2) Fabricate a special press-fitting jig. Fit the bearing in

the tension pulley using the jig and a hand-press.

Note: The bearing is a grease-filled type. Do not wash the

bearing.

Inner ball bearing - Insert

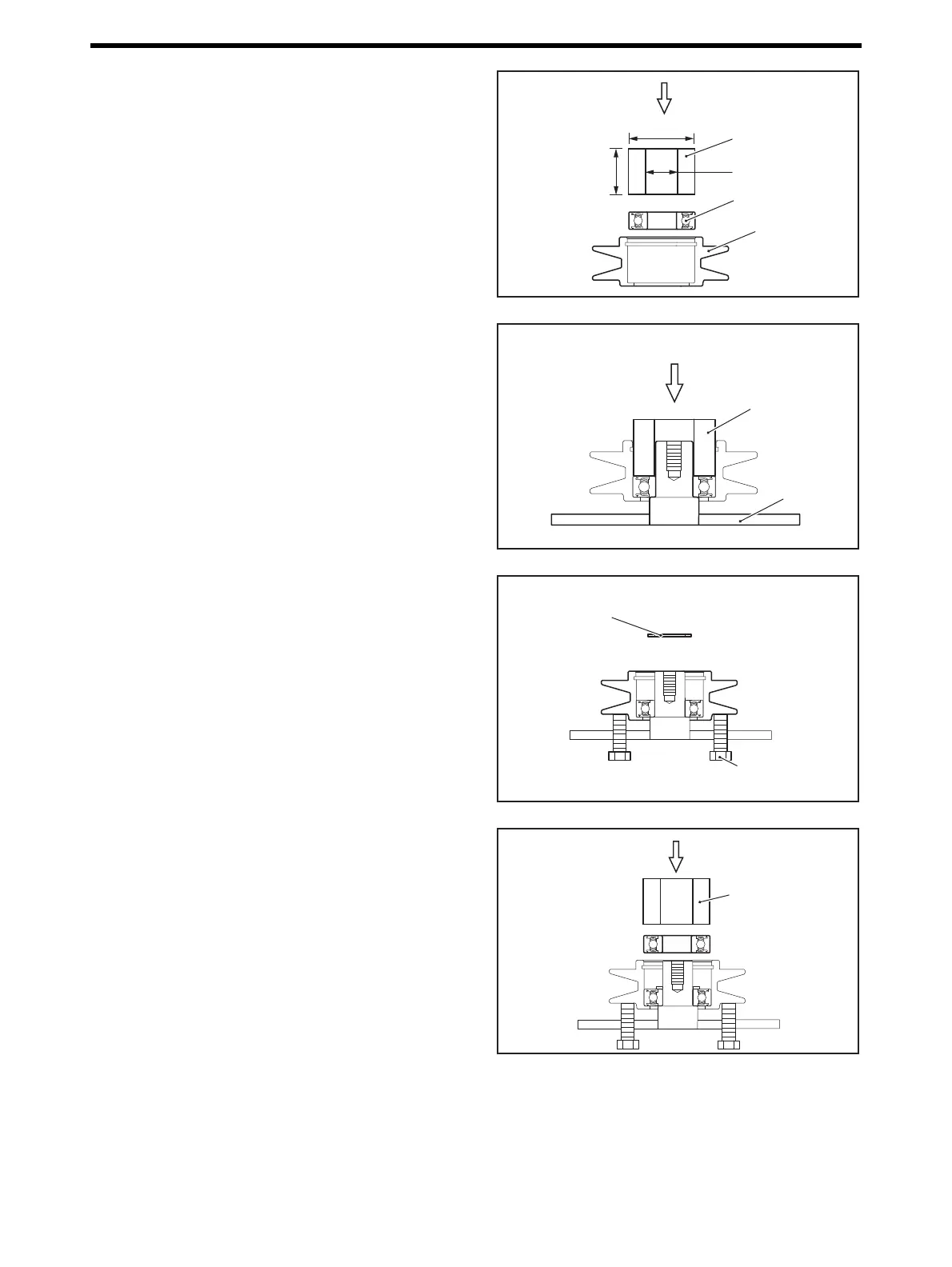

(3) Fit the inner ball bearing onto the bracket using a hand-

press.

Tension pulley - Insert

(4) Install the inside spacer.

(5) Screw two bolts into the extracting bolt holes in the

bracket from the inside to hold the tension pulley

lightly.

Spacer and Bolt - Install

(6) Fit the outer ball bearing into the tension pulley using

the special jig and a hand-press.

Outer ball bearing - Insert

Special jig

Bearing

ø 52 [2.05]

34

[1.34]

ø 20

[0.8]

Unit: mm [in.]

Tension pulley

Special jig

Bracket

Spacer

Bolt

M12×1.25 (2 pcs.)

Umit: mm [in.]

Special jig

Loading...

Loading...