7-9

Chapter 7 ASSEMBLY OF BASIC ENGINE

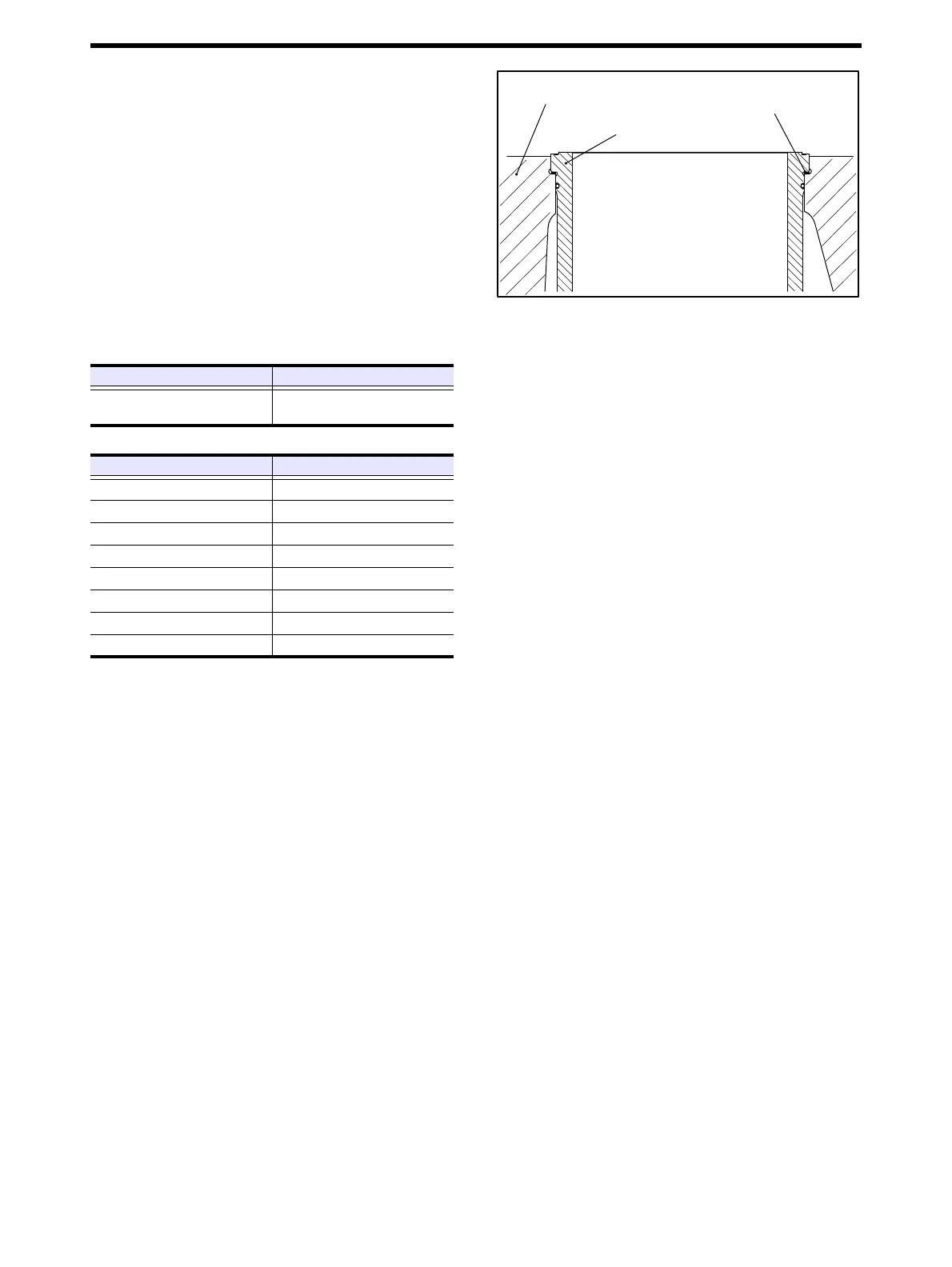

(5) Calculate the cylinder liner flange protrusion by sub-

tracting the depth of counterbore in crankcase from the

thickness of the cylinder liner flange.

If the value exceeds the limit, insert a shim under the

cylinder liner flange.Select a shim which makes the

cylinder liner flange protrusion the largest within the

tolerance of the standard.

Note:(a) Shims are available in thicknesses of 0.05, 0.10,

0.15, 0.20, 0.25, 0.30, 0.35, 0.40 mm [0.0020,

0.0039, 0.0059, 0.0079, 0.0098, 0.0118, 0.0138,

and 0.0157 in.].

(b) Do not double the shims.

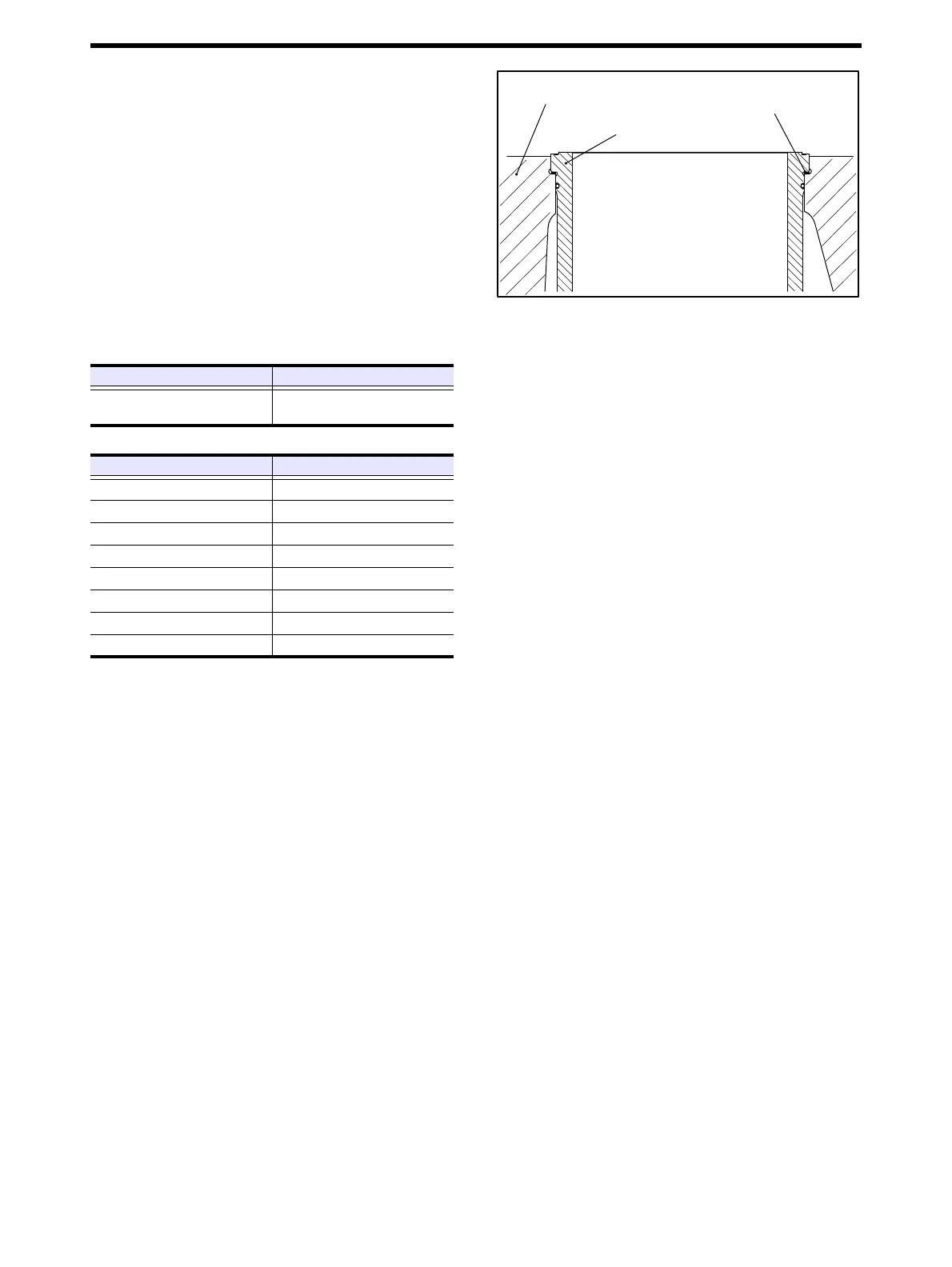

Shim - Insert

Item Standard value

Cylinder liner flange

protrusion

0.10 to 0.19 mm

[0.0039 to 0.0075 in.]

Shim thickness Part No.

0.05 mm [0.0020 in.] 35A07-17500

0.10 mm [0.0039 in.] 35A07-17100

0.15 mm [0.0059 in.] 35A07-17600

0.20 mm [0.0079 in.] 35A07-17200

0.25 mm [0.0098 in.] 35A07-17700

0.30 mm [0.0118 in.] 35A07-17300

0.35 mm [0.0138 in.] 35A07-17800

0.40 mm [0.0157 in.] 35A07-17400

Shim

Crankcase

Cylinder liner

Loading...

Loading...