SECTION 3 -- FIELD OPERATION

3--132

MOVING A WHEEL ON THE AXLE SHAFT

Block the front wheels and jack up and support the

rear axle.

Adjustment of the track setting is achieved by sliding

the complete wheel/hub assembly on the axle shaft.

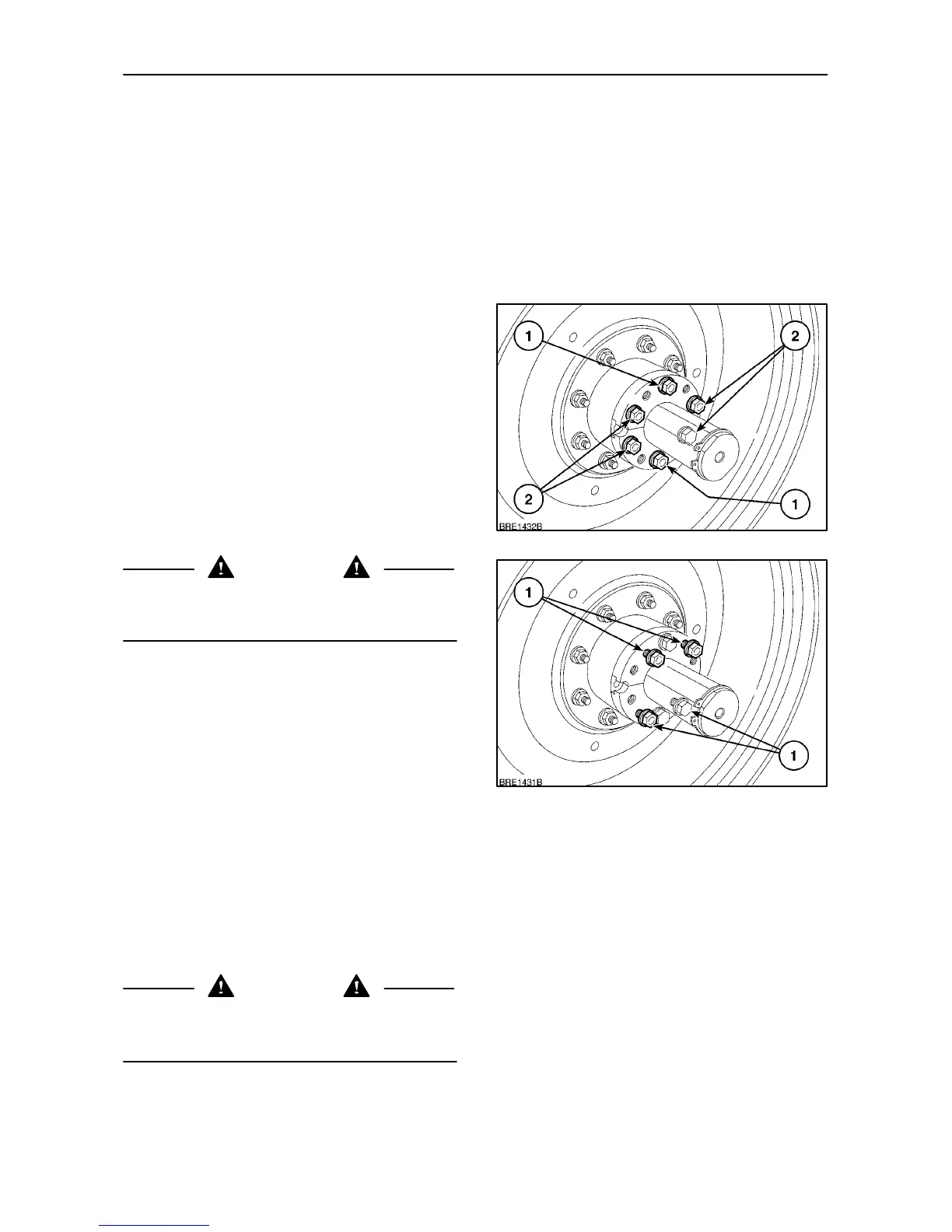

Loosent he t wocent rewedgebolt s( 1) Figur e 227,

approximately 0.5 in. (12 mm). Remove the f our

outer wedge bolt s (2) .

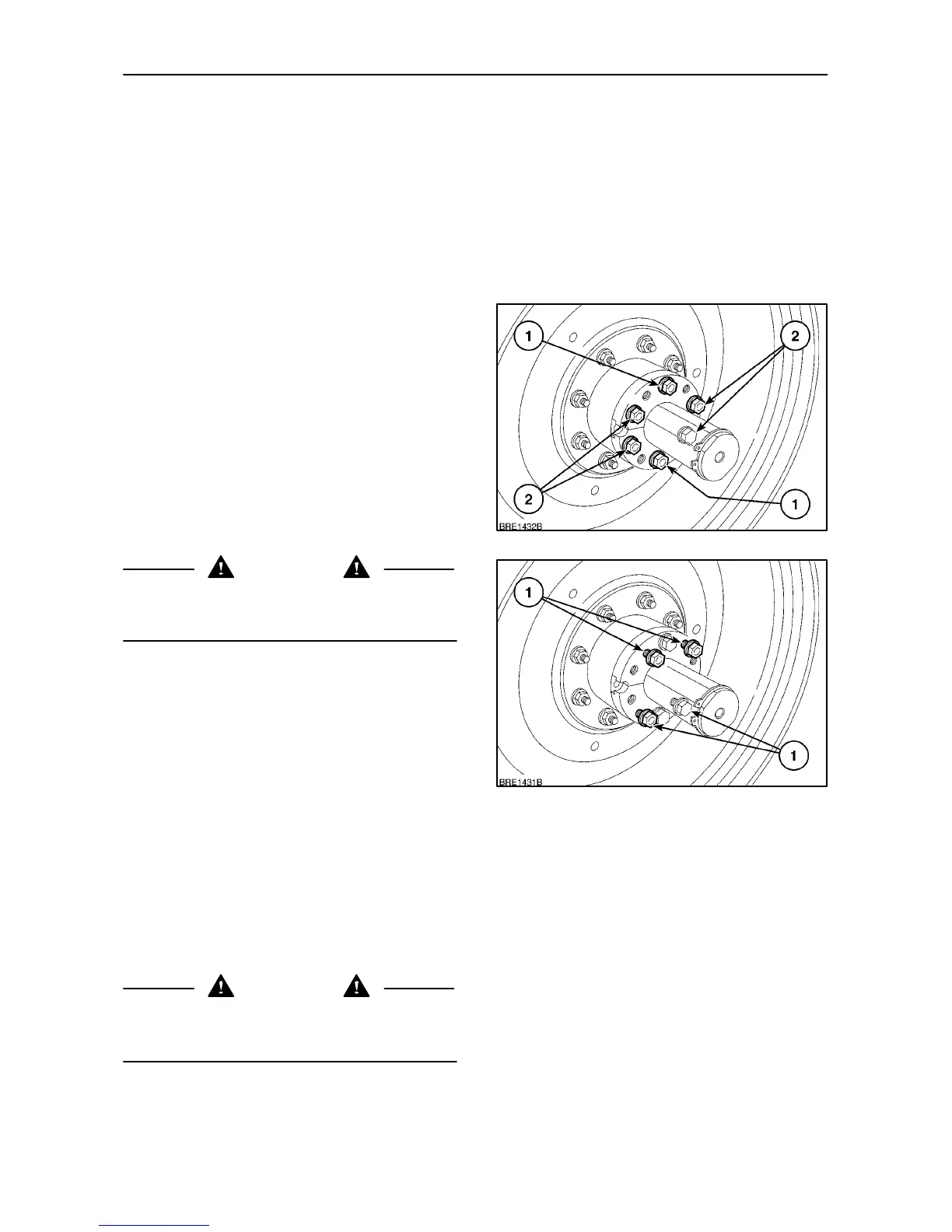

Clean the bolts and threaded holes in the wedges

before lubricating and installing the outer wedge

bolts at (1) Figure 228. These bolts are used as jack

bolts to push against the wedges. T ighten the jack

bolts evenly until the wedges loosen on the axle

shaft. The wheel assembly will now be free to slide

in or out on the axle shaft.

IMPORTANT: Do not use a torque greater than 300

ft.lbs. (407 N⋅m) on the jack bolts. The use of

penetrating oil between the wedge and axle shaft will

be of benefit. If difficulty is experienced, place a shaft

protector over the end of the axle shaft and strike with

a hammer to ‘shock’ the wedge free.

227

WARNING

Take suitable precautions, including the use of safety

glasses, against the possibility of flying metal

particles.

Set the wheel to the desired position on the shaft.

Remove the jack bolts and replace them in the outer

holes (2) Figure 228.

T ighten all six wedge retaining bolts in increments

of 50 ft.-lbs. (68 Nm) until a final torque of 221 ft.-lbs.

(300 Nm ) is achieved.

IMPORTANT: The wedge bolts must be tightened

evenly.

228

Repeat the procedure on the other wheel, making

sure that both rear wheels are the same distance

from the ends of the axle shafts.

NOTE: Check the torque of all six wedge retaining

bolts on each wheel after driving the tractor for 200

yards (200 m), after 1 hour and 10 hours operation

and thereafter at the 50-hour service intervals.

WARNING

Never operate the tractor with a loose wheel rim or

disc. Always tighten nuts to the specified torque and

at the recommended intervals.

Loading...

Loading...