ENGLISH – 7

3.5 PRE-INSTALLATION WORKS

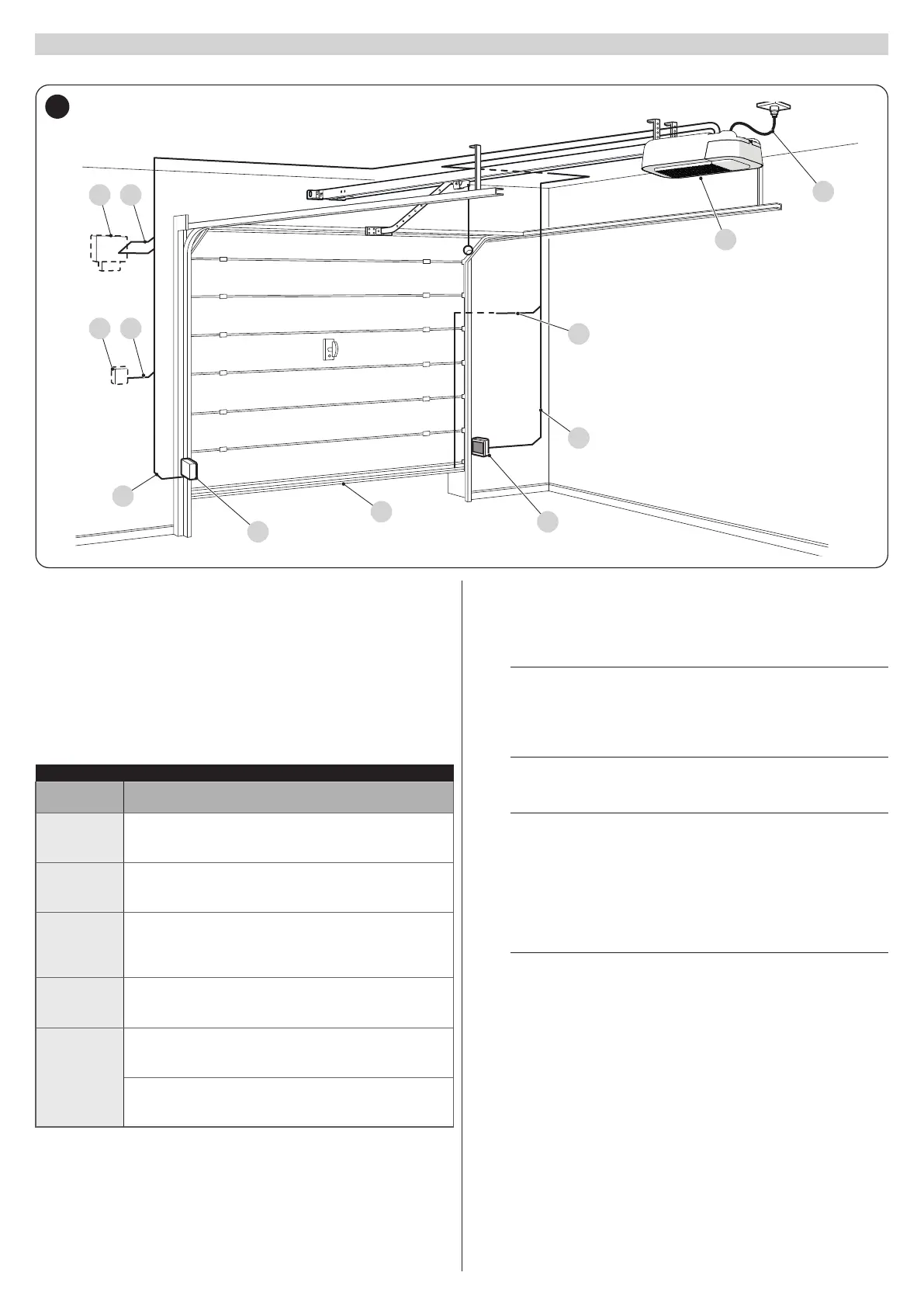

The gure shows an example of an automation system, constructed using Nice components.

A

1

2

B

3

C

4D

5E

B

3

5

A Gearmotor

B Photocells

C Main edge

D Key selector

E Warning light with incorporated antenna

The above-mentioned components are positioned according to a typical

standard layout. Using the layout shown in “Figure 5” for reference, dene

the approximate position in which each component of the system will be

installed.

Table 4

TECHNICAL SPECIFICATIONS OF ELECTRICAL CABLES

Identication

no.

Cable characteristics

1

GEARMOTOR POWER SUPPLY cable

1 cable 3 x 1.5 mm

2

Maximum length 30 m [note 1]

2

MAIN EDGE cable

1 cable 2 x 0.5 mm

2

Maximum length 20 m

3

PHOTOCELL cable

2 x 0.7 mm

2

BlueBus

4 x 0.5 mm

2

standard

Maximum length 30 m

4

KEY SELECTOR cable

2 cables 2 x 0.5 mm

2

[note 2]

Maximum length 50 m

5

WARNING LIGHT cable

1 cable 2 x 0.5 mm

2

Maximum length 20 m

ANTENNA cable

1 x RG58-type shielded cable

Maximum length 10 m; recommended < 5 m

Note 1 If the power supply cable is longer than 30 m, a cable with larger

cross-sectional area (3 x 2.5 mm

2

) must be used and a safety

earthing system must be installed near the automation.

Note 2 These two cables can be replaced by a single 4 x 0.5 mm

2

cable.

a

Before proceeding with the installation, prepare the re-

quired electrical cables by referring to “Figure 5” and to

that stated in the “TECHNICAL SPECIFICATIONS” chap-

ter (page 59).

a

The cables used must be suited to the type of environ-

ment of the installation site.

a

When laying the pipes for routing the electrical cables,

take into account that any water deposits in the junction

boxes may cause the connection pipes to form conden-

sate inside the control unit, thus damaging the electronic

circuits.

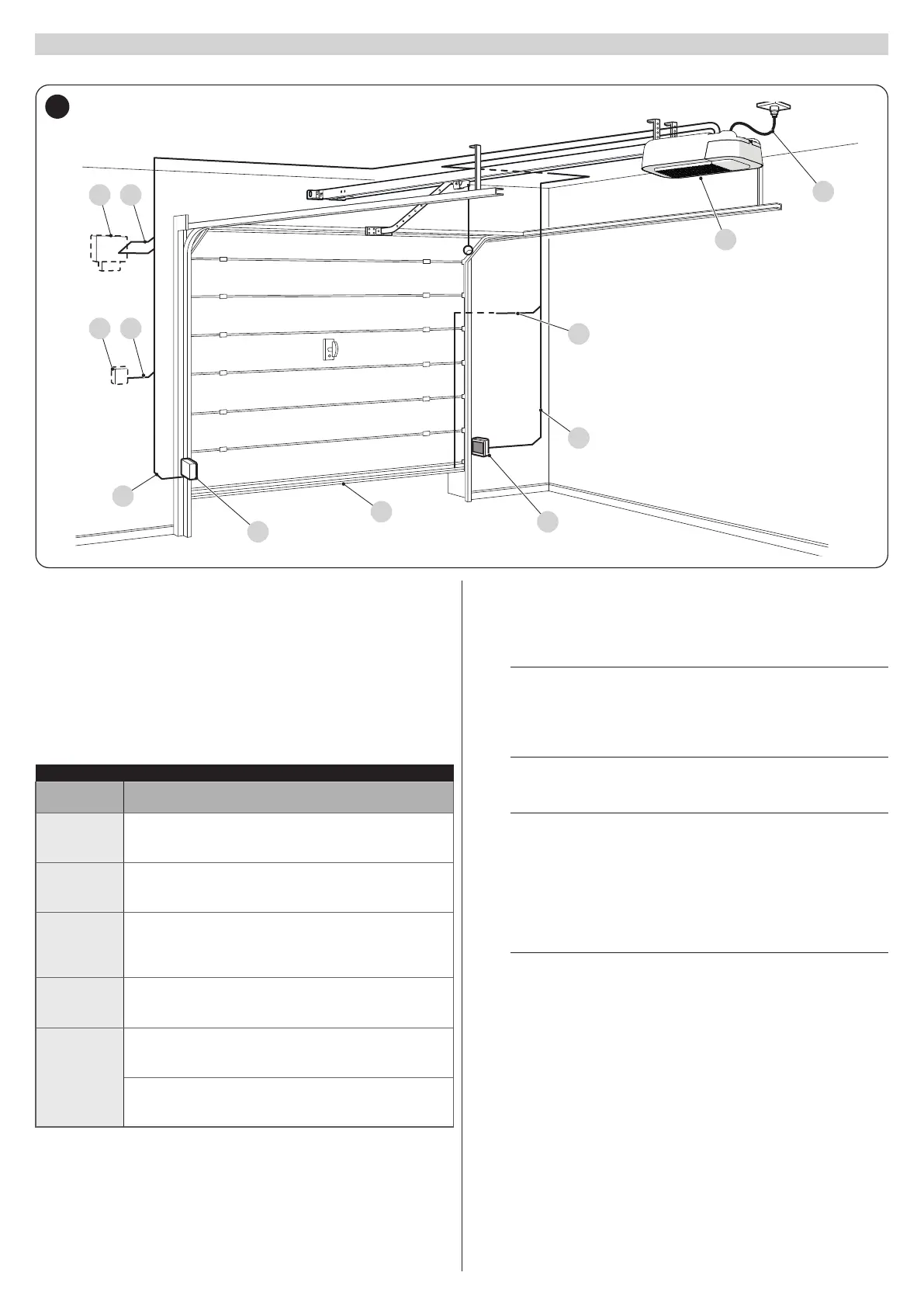

“Figure 6” shows typical installations for a protruding and non-protruding

overhead door.

m

For installation on protruding and non-protruding doors,

accessory SPA5 is required.

Loading...

Loading...