3 Specifications

3 - 62

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

3-5 Cable and Connector Specifications

The specifications of the cables that connect the Servo Drive with a Servomotor are shown below. The

information on the connectors is also provided.

Select an appropriate cable for the Servomotor.

If the cable is used in a moving environment, use a global flexible cable.

Regarding the bending life of a global flexible cable, a wire rod with a durability of more than 20 million

times of use at or above the minimum bending radius is used under the conditions below.

Precautions for Correct UsePrecautions for Correct Use

• Because the life expectancy data on resistance to bending is intended for reference only, use

the cable with a sufficient margin.

• The durability of more than 20 million times of use refers to the number of times which the core

conductor provides electrical continuity without causing cracks and scratches that can have

functional impact on the sheath, which does not cover the disconnection of shielded wire.

• Malfunction or grounding fault due to dielectric breakdown may occur if cables are used at a

radius smaller than the minimum bending radius.

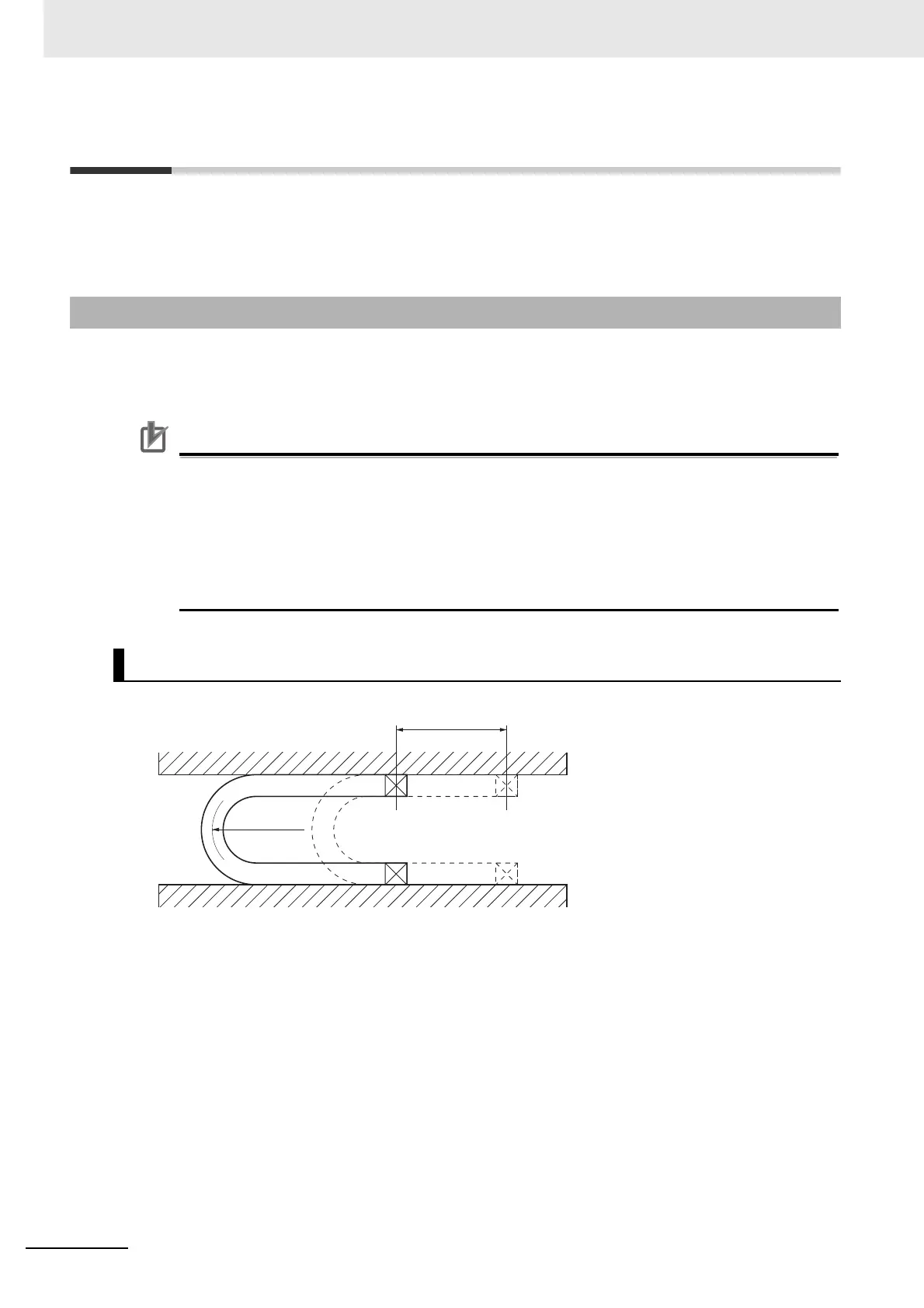

3-5-1 Resistance to Bending of Global Flexible Cable

Moving Bend Test

Stroke

750 mm

Bending

radius (R)

30 times/min