FUSING

G104 6-58 SM

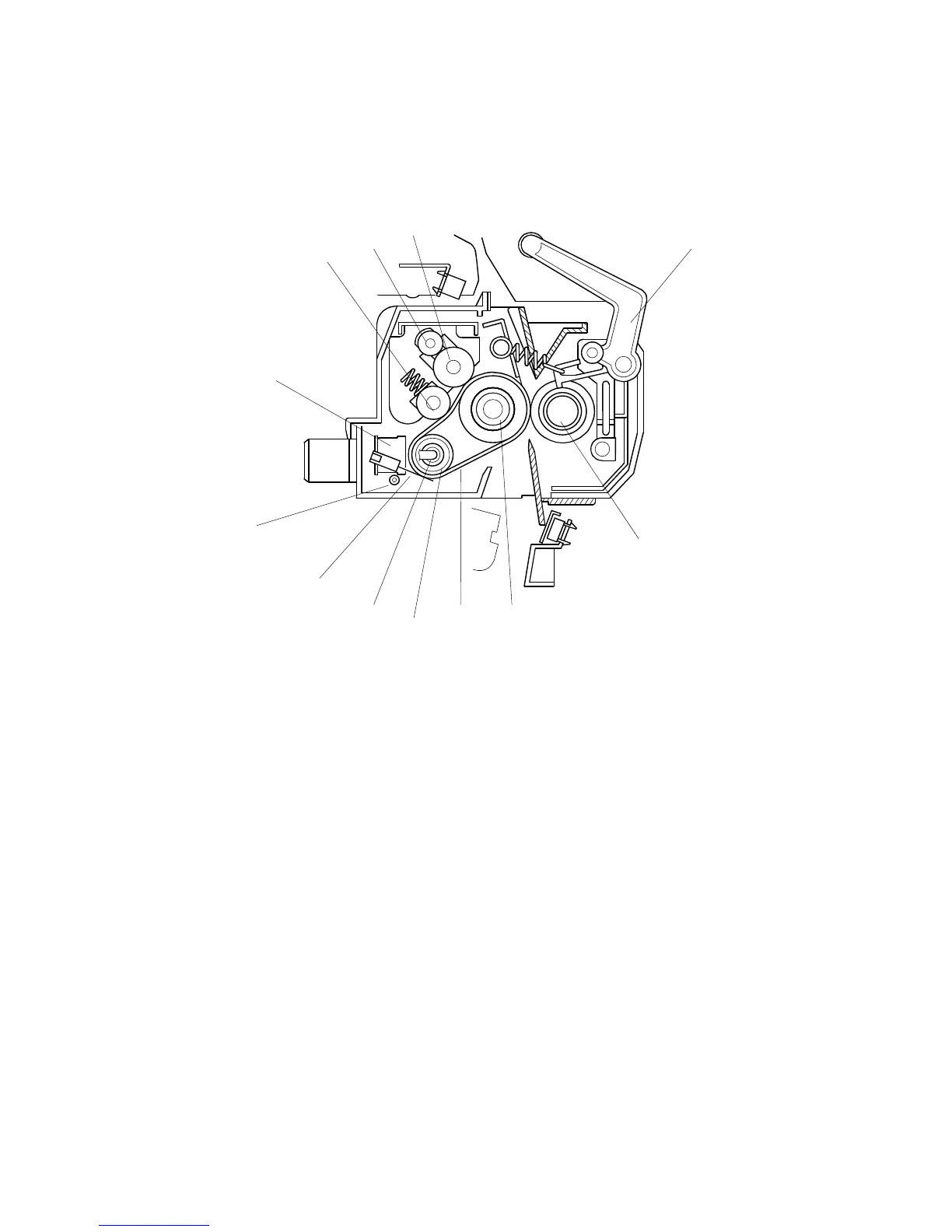

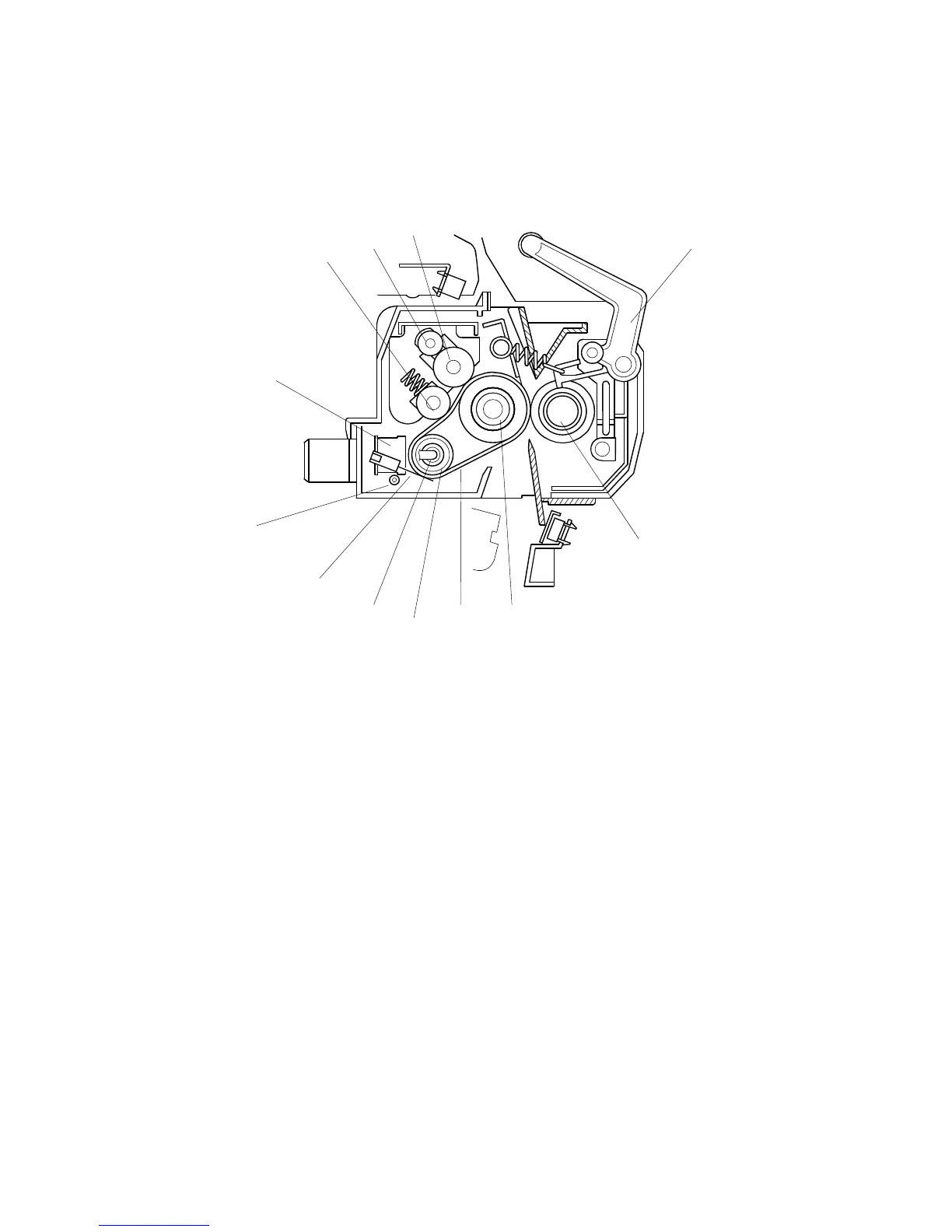

6.8 FUSING

6.8.1 OVERVIEW

1. Fusing tension roller

2. Cleaning roller

3. Oil supply roller

4. Pressure lever

5. Pressure roller

6. Hot roller

7. Fusing belt

8. Heating roller

9. Heating lamp

10. Thermistor

11. New fusing unit

detection fuse

12. Thermostat

• For this model, a belt fusing system is used. This system has a faster warm-up

time than a standard hot and pressure roller system.

• The heating roller is made of aluminum to increase the temperature of the fusing

belt quickly.

• The hot roller is made of sponge, which becomes a little flat at the contact point

of the pressure roller. This increases the fusing nip. This roller does not contain a

heating lamp.

• The heating roller thermistor controls the temperature of the lamp.

• Each new fusing unit contains a fuse. A short time after a new fusing unit is

installed, this fuse blows. When this occurs, the machine detects that a new

fusing unit is installed.

The oil supply roller supplies oil to the fusing belt through the oiling roller. This

mechanism applies a constant thickness of oil to the fusing belt.

G105D118.WMF

1

2

3

4

5

679

10

12

8

11

Loading...

Loading...