Process Control

SM 6-9 G160/G161

G160/G161

sensor output value from each gradation of the pattern.

Step 5: V

D

, V

B

, V

L

Selection and V

REF

Adjustment

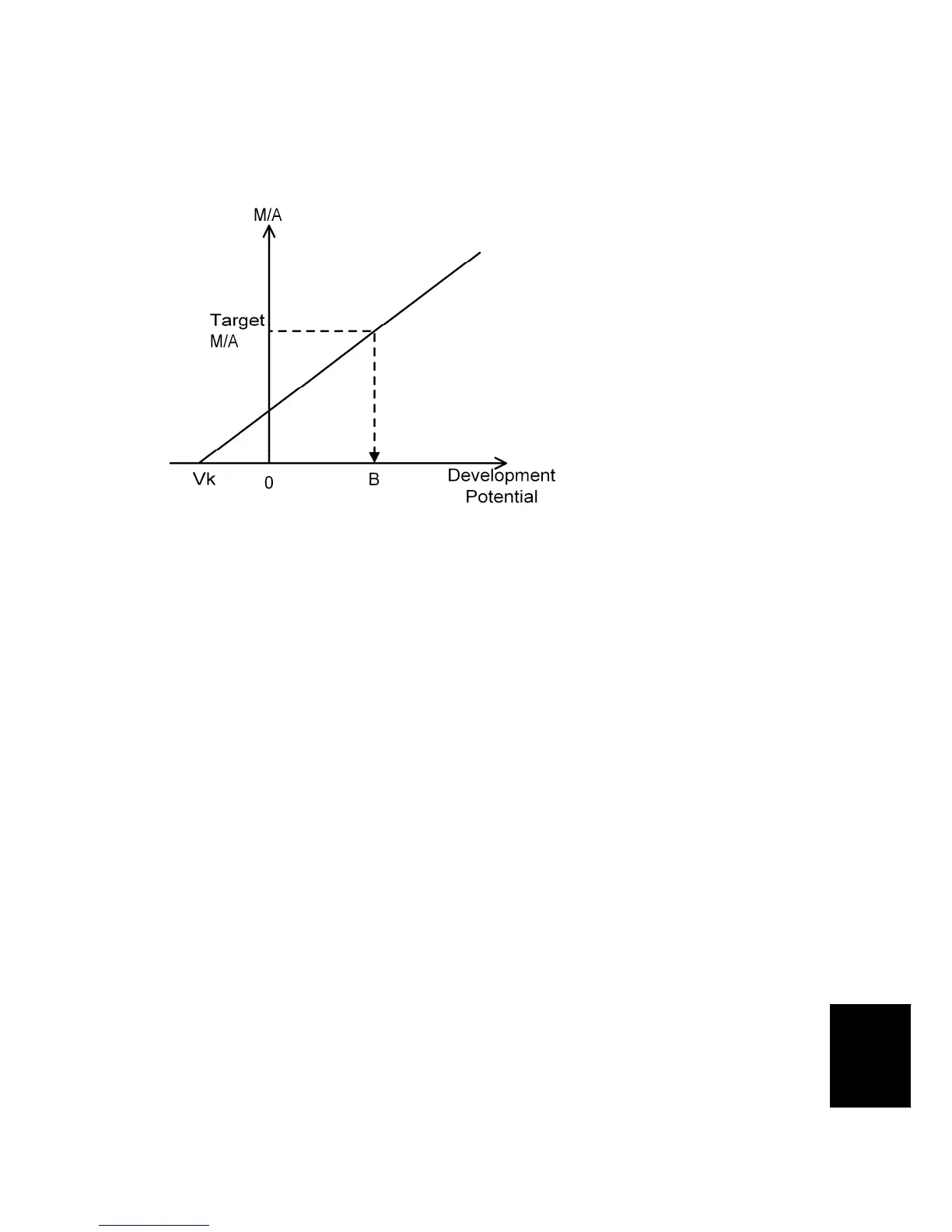

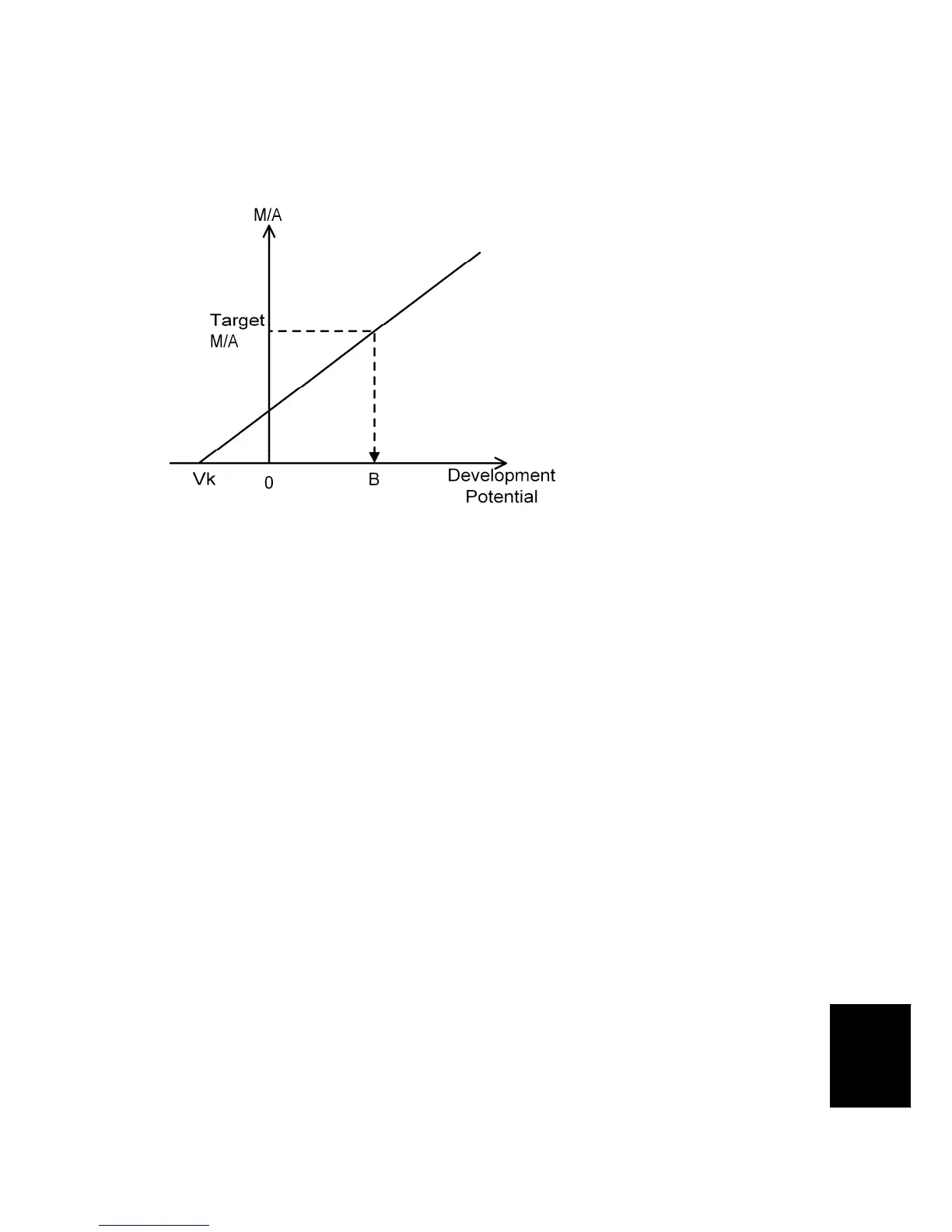

The machine makes a plot of the 10 values of M/A against the development potential that

was used to make each of the gradations. Then it makes a line through the 10 points.

Then, it finds the development potential that is necessary to put the ‘target M/A’ of toner on

the OPC.

This development potential is then used to find the best values of development bias,

charge roller voltage and laser power for the machine in its current condition. To do this, it

refers to a table in memory.

The machine also adjusts V

REF

(toner density target) at the same time. As a result, the

development gamma detected by process control will be the value stored in SP 3561 1 to 4

(do not adjust in the field unless told to do this).

After that, the transfer belt cleaning unit cleans the transfer belt.

6.3.3 TONER SUPPLY CONTROL

Toner Supply Control Modes

This machine has four toner supply control modes. They are selected with SP 3301 1 to 4.

1. Fixed supply mode

This mode is used when the TD sensor becomes defective. The amount of toner supply

can be adjusted with SP 3302 1 -4 if the image density is incorrect (the default setting is

5%).

2. Proportional control mode 1 (Pixel)

This mode is used when the TD sensor becomes defective. Only the pixel count is used to

control toner supply. The amount of toner supply can be adjusted with SP 3306 1 to 4.

3. Proportional control mode 2 (TD sensor)

Loading...

Loading...