PROCESS CONTROL RESULT

SM 4-1 G104

Trouble-

shooting

4. TROUBLESHOOTING

4.1 PROCESS CONTROL RESULT

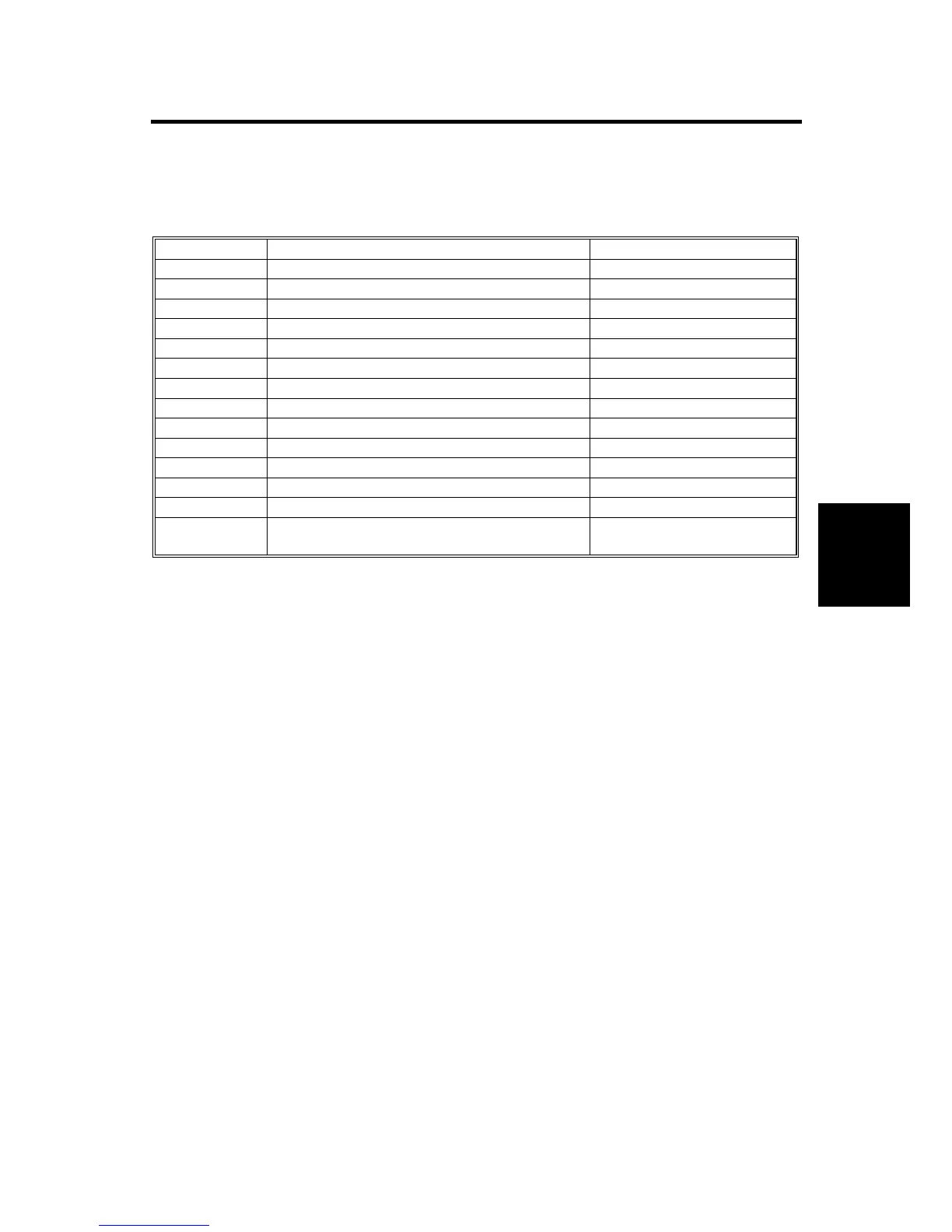

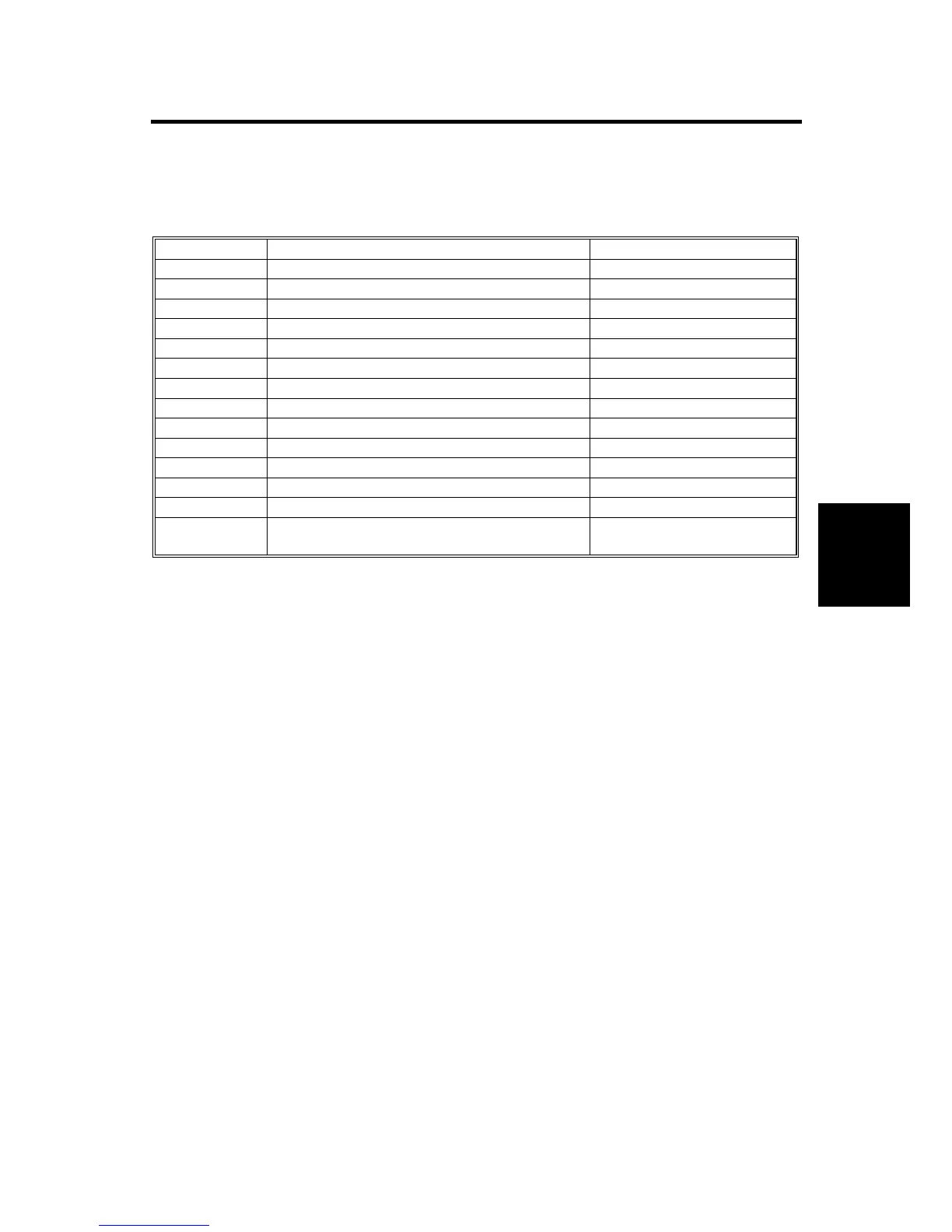

The table below lists the process control results shown in SP 3821.

Number Result Notes

10 Success No error

21 ID sensor correction error SC 400

22 ID sensor: LED adjustment error SC 418

31 Charge bias correction error SC 300 to 307

51 High Vmin (Bk), High K2 (Color) error SP3145 NOTE

52 Low K2 (Color) error SP3146 NOTE

53 High K5 error SP3147 NOTE

54 Low K5 error SP3147 NOTE

55 High development gamma

γ > 5.0, NOTE

56 Low development gamma

γ < 0.5, NOTE

57 Development bias adjustment error Vk >150V NOTE

58 Development bias adjustment error Vk < -150V NOTE

90 No process control -

99 Not successful

Interrupt during the process

control (e.g. Door open)

NOTE: This error code does not usually occur. Although an error code may be

displayed, if no problem is observed with image density and/or

development gamma, nothing needs to be done. If an image problem such

as low image density is observed, check the following points: Transfer belt

/ PCU / ID sensor / Toner Bottle

The 8 numbers on the LCD in SP 3821 indicate the process control result for each

color.

There are two numbers for each color. The numbers are shown from left to right on

the display as follows: Black, Magenta, Cyan, Yellow.

For example, if process control for each color is successful:

10101010

10 (Black), 10 (Magenta), 10 (Cyan), 10 (Yellow)

If a problem is detected during process control:

10515110

10 (Black), 51 (Magenta), 51 (Cyan), 10 (Yellow)

Loading...

Loading...