Tracking

Parameters

Linear Conveyors

When a linear conveyor is selected, a line feature must be configured in the

Features part of the installation to determine the direction of the conveyor. Ensure

accuracy by placing the line feature parallel to the direction of the conveyor, with a

large distance between the two points that define the line feature. Configure the line

feature by placing the tool firmly against the side of the conveyor when teaching the

two points. If the line feature’s direction is opposite to the conveyor’s movement,

use the Reverse direction button. The Ticks per meter field displays the number of

ticks the encoder generates when the conveyor moves one meter.

Circular Conveyors

When tracking a circular conveyor, the conveyor center point must be defined.

1. Define the center point in the Features part of the installation. The value of

Ticks per revolution must be the number of ticks the encoder generates

when the conveyor rotates one full revolution.

2. Select the Rotate tool with conveyor checkbox for the tool orientation to

track the conveyor rotation.

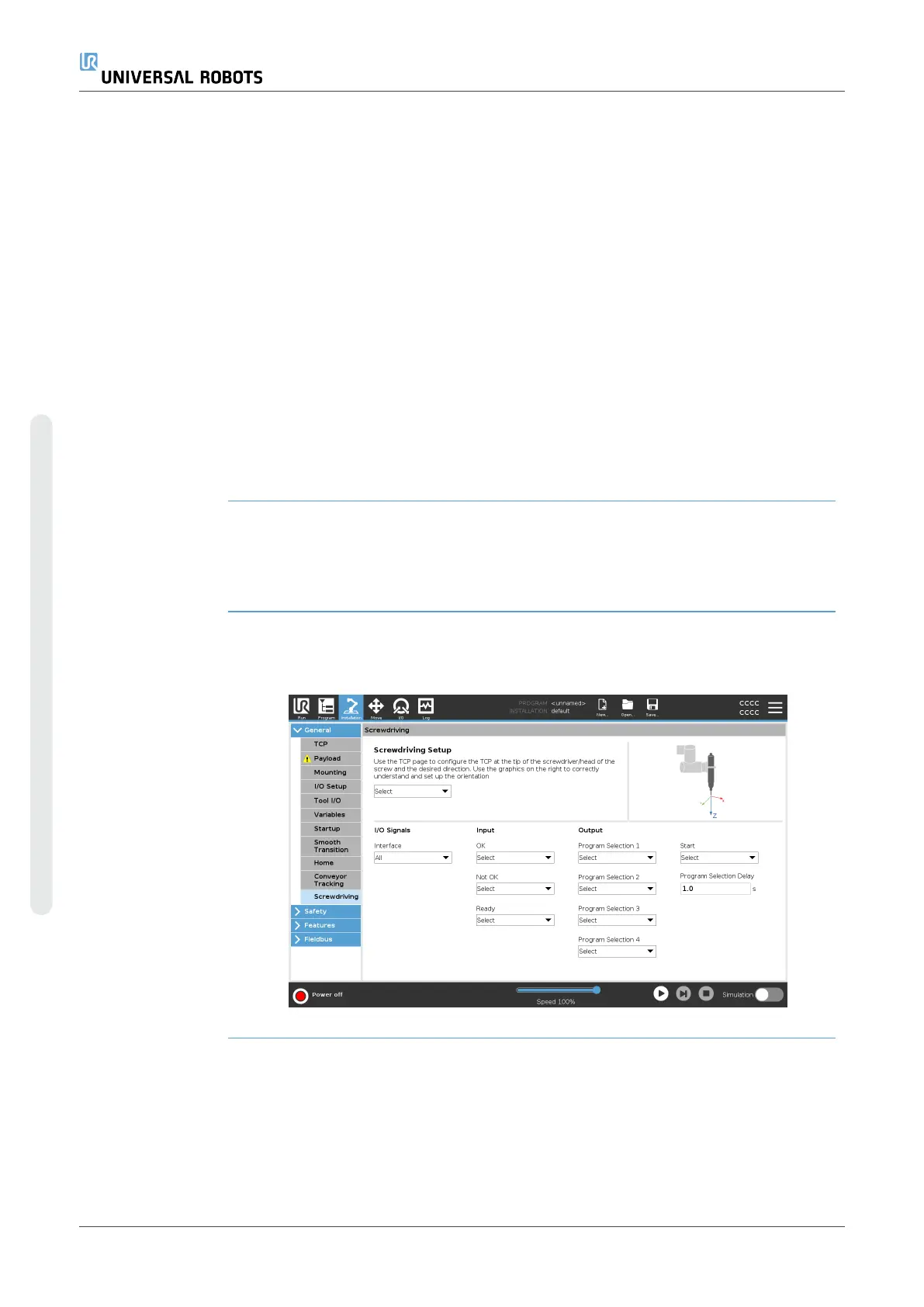

20.11. Screwdriving Setup

Description The Screwdriving Setup provides options for configuring the robot to work with an

industrial screwdriver or an industrial nutrunner. You can setup the screwdriver’s

position with respect to the robot’s tool flange and electrical interface.

UR10e 296 User Manual

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...