ACTA 4000 User Guide Printouts from ACTA

9836 4171 01 2008-12 121 (136)

9.3 Capability studies

The purpose of capability studies is to indicate how well a process or machine performs within the

tolerance limits. As for control charts, the method described below is only applicable to normal

distributions.

Most commonly used are the ordinary machine capability index, CM, and the modified machine capability

index, CMK. CM is defined as the ratio of tolerance interval and the six sigma interval:

6σ

)(toleranceMin )(toleranceMax

CM

−

=

Equation 10 Machine capability (CM) definition

A common requirement is for the CM-value to exceed 1.33. This indicates that six times the standard

deviation covers no more than 75% of the tolerance interval.

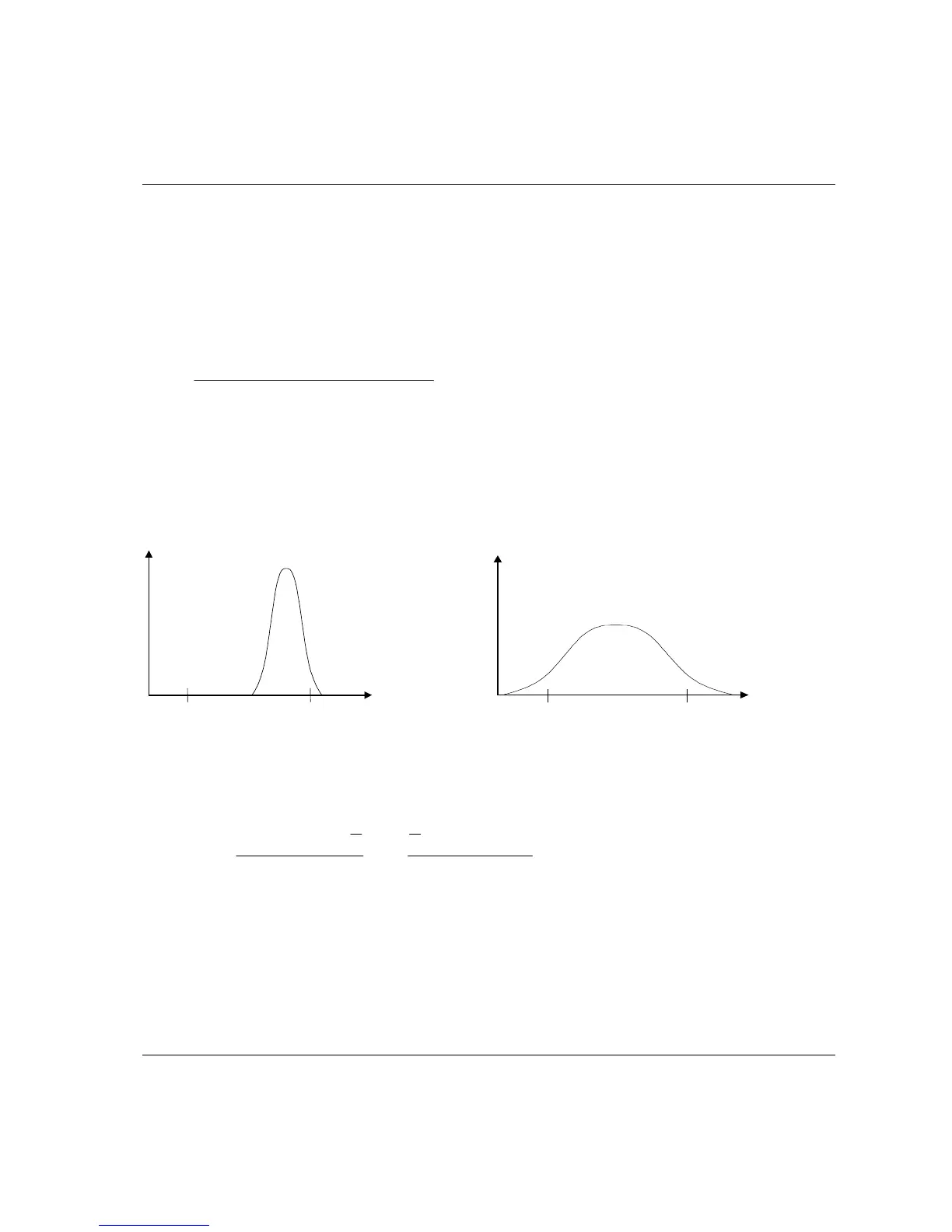

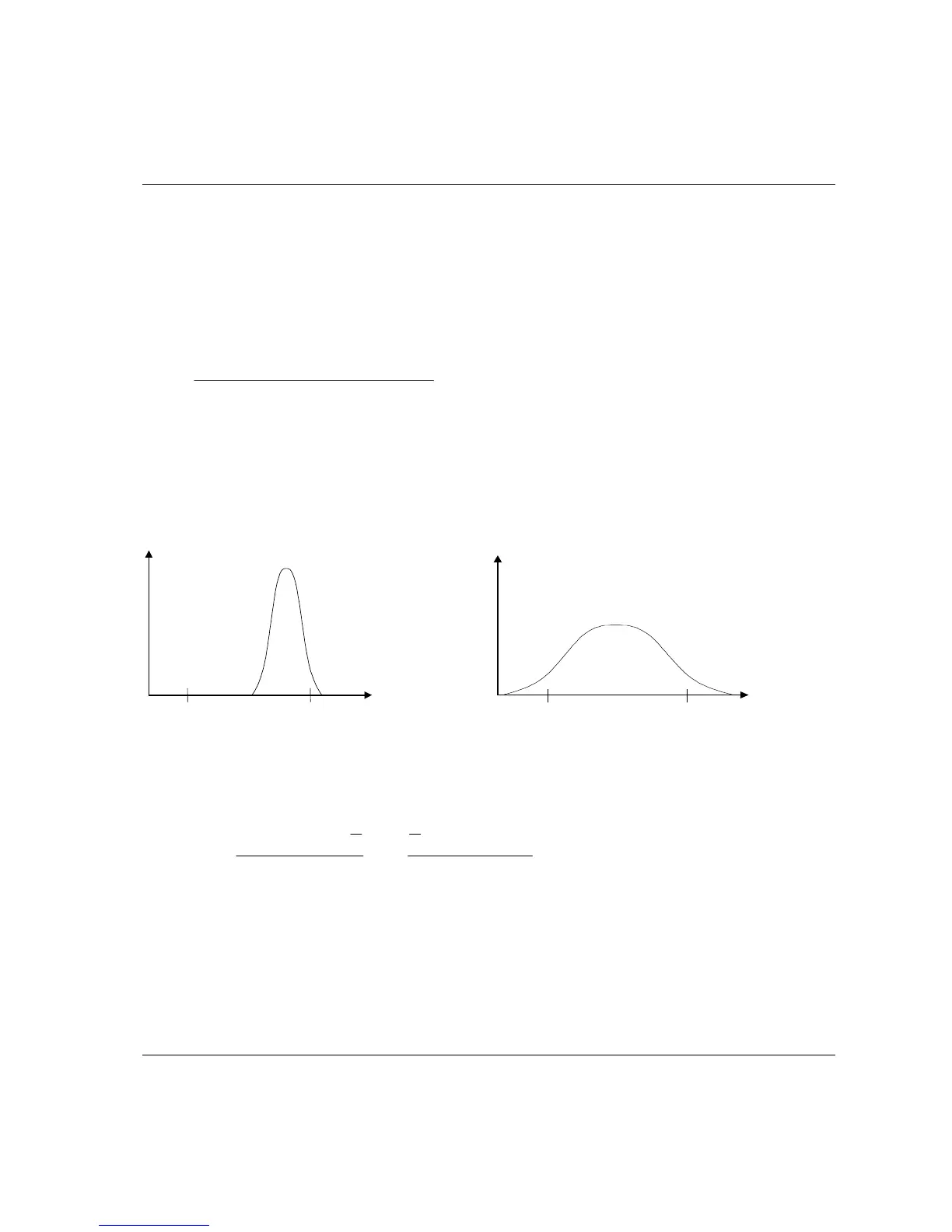

However, this index does not ensure that the distribution is centered in the middle of the tolerance interval.

The process may still perform outside of the tolerance interval, even if the scatter is small.

Min Max

Min Max

Figure 7 High CM, badly centered process Figure 8 Low CM, well centered process

The modified process capability index takes into account both setting and spread of data. CMK is defined

by Equation 11:

()

−

33

toleranceMinX

or

XtoleranceMax

ofMinimum

Equation 11 Modified Machine Capability (CMK) definition

The most common CMK requirement is at least 1.33. Some manufacturers require CMK of 1.5 or more.

Loading...

Loading...