Engine

Installing Rotor to Crankshaft.

1.

Inspect tapered portion of crankshaft for

damage. If small imperfections or burrs

exist clean with a fine file or emery cloth. If

necessary, lap crankshaft and rotor wit

h

180 grit lapping compound.

2.

Clean tapered surfaces of crankshaft and

r

otor with brake parts cleaner or other quick

evaporating cleaner.

3.

Install woodruff key into crankshaft.

Note: Ensure that top of woodruff key is

par

allel with the tapered portion of t

he

cr

ankshaft.

4.

Slide flywheel onto the crankshaft.

5.

Securing flywheel.

•

On 2019+ units install the M22 nut

and torque to 160 Nm.

•

On Prior years slide the fan hub

ag

ainst the rotor. Run a bolt in the

end of the crankshaft and remove 3

x

at

a force not exceeding 70 Nm.

Discard bolt.

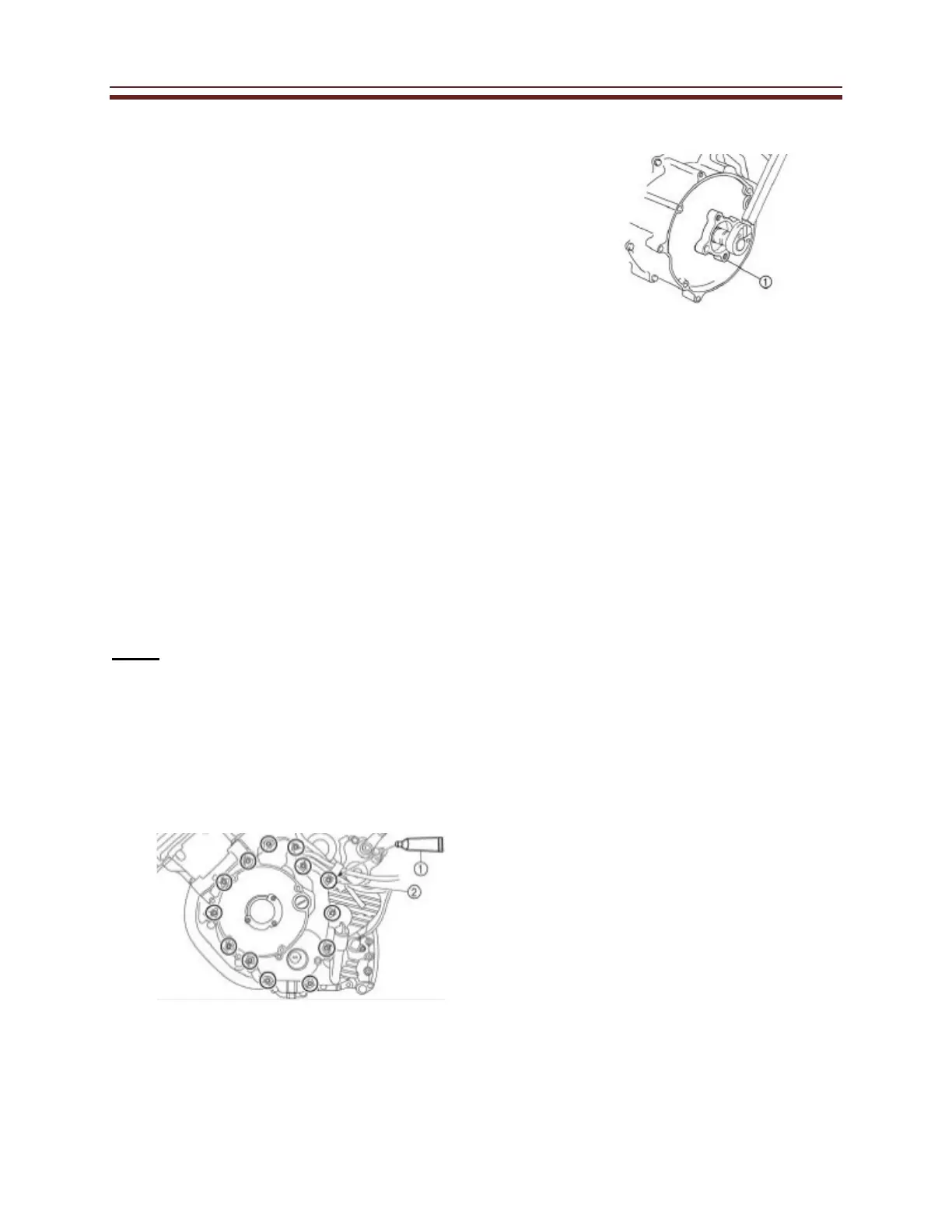

Note:

When installing the A.C. Magneto cover

use a long rod to hold the A.C. Magneto

rotor in position from the outside. This

will make assembly easier. Be careful not

to damage the oil seal. Apply sealant (1)

to the bolt threads (2) shown in this

illustration.

Before installing the engine cooling

fan pulley, do not forget to install the

O-ring.

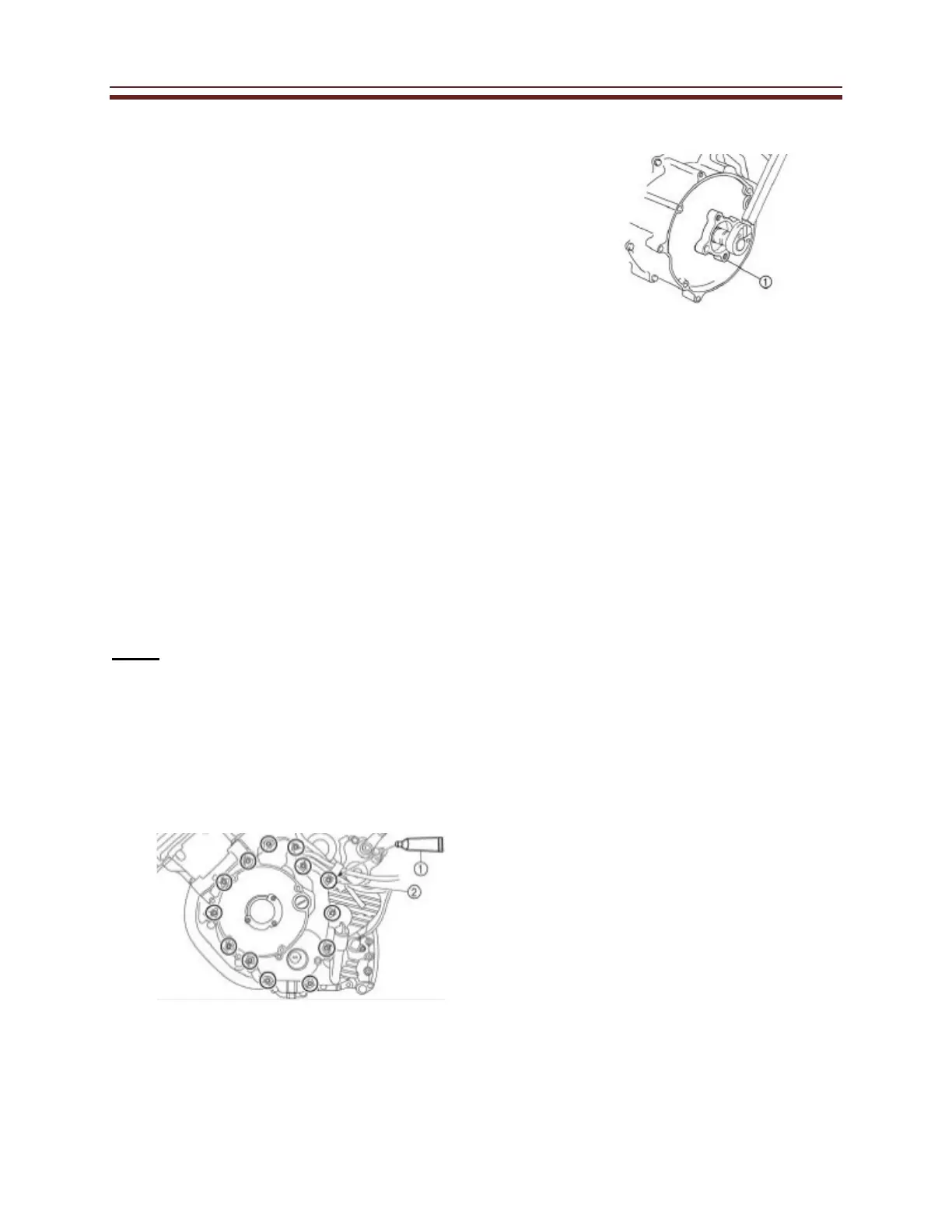

Install Engine cooling fan Pulley (1)

75 Nm or 55 ft lbs

Note: Do not reuse bolt used to

secure fan hub.

Loading...

Loading...