General Information

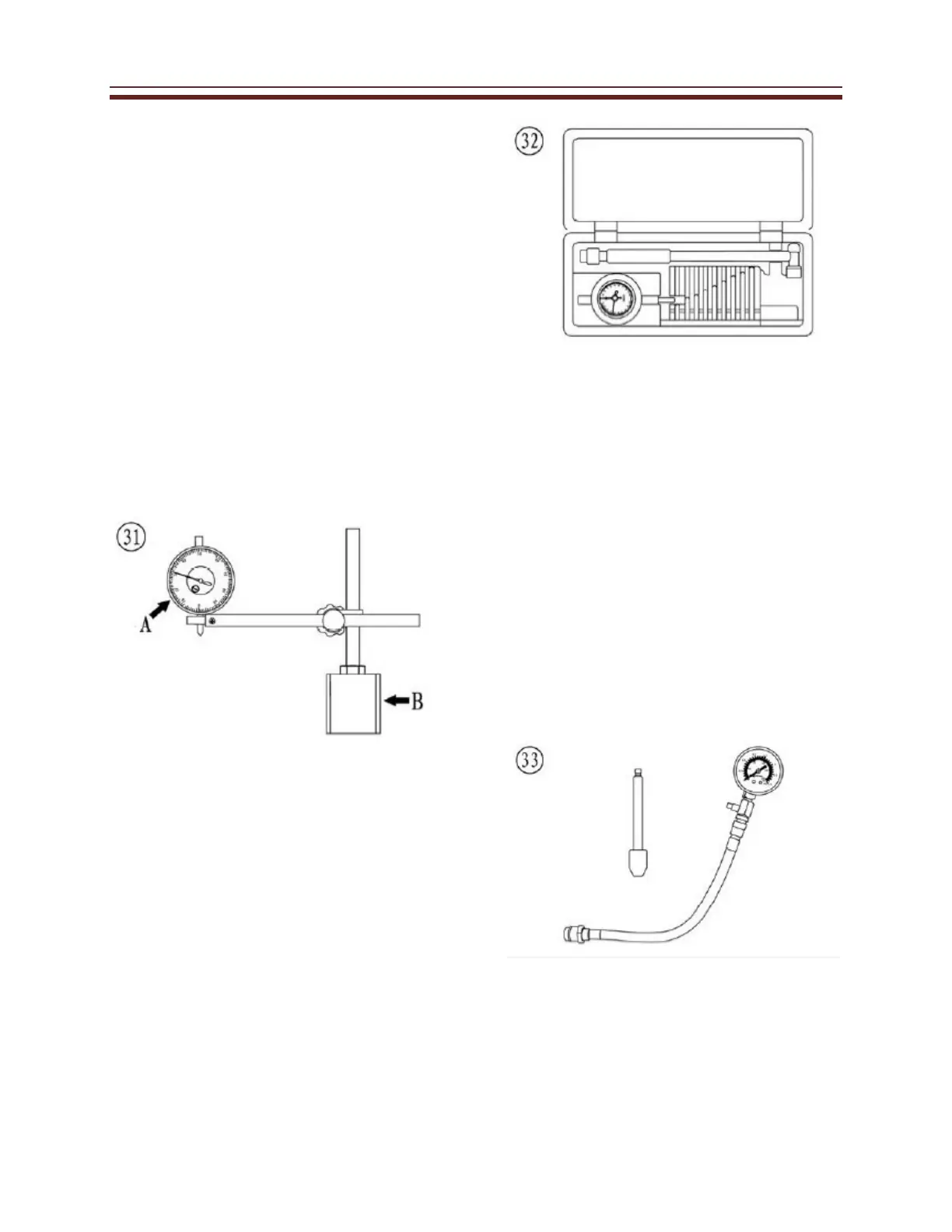

Dial Indicator

A dial indicator (Figure 31) is a gauge

with a dial face and needle used to

measure variations in dimensions and

movements. Measuring brake rotor run

out is a typical use for a dial indicator.

Dial indicators are available in various

ranges and graduations and with three

basic types of mounting bases:

magnetic (B. Figure 31). Clamp, or

screw-in stud. When purchasing a dial

indicator, select one with a continuous

dial (A, Figure 31). Cylinder Bore

Gauge.

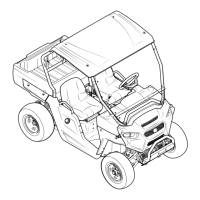

A cylinder bore gauge is similar to a dial

indicator. The gauge set shown in

(Figure 32) consists of a dial indicator,

handle, and different length adapters

(anvils) to fit the gauge to various bore

sizes. The bore gauge is used to

measure bore size, taper and out-of-

round. When using a bore gauge, follow

the manufacturer’s instructions.

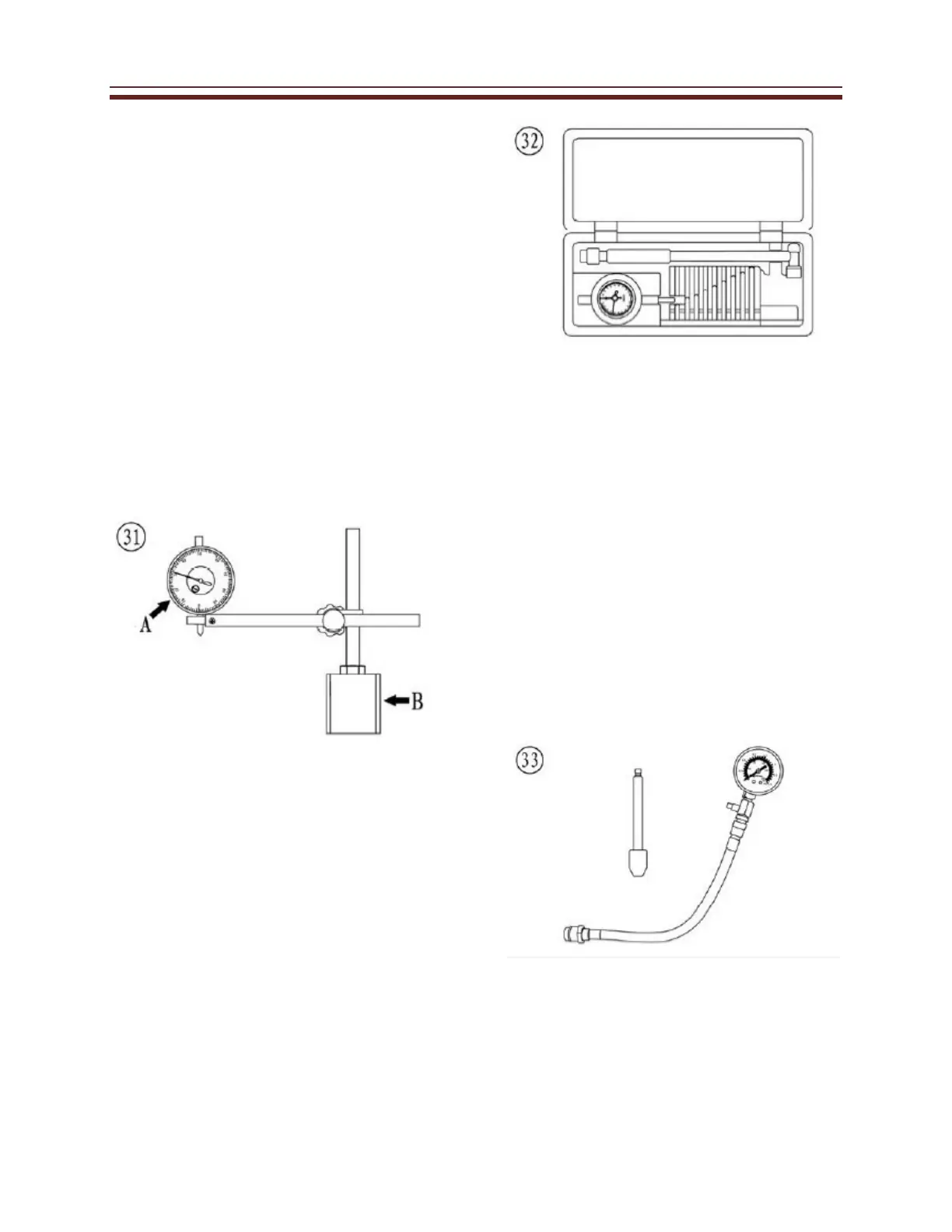

Compression Gauge

A compression gauge (Figure 33)

measures combustion chamber

(cylinder) pressure, usually in PSI or

kg/2

cm. The gauge adapter is either

Inserted or screwed into the spark plug

hole to obtain the reading. Disable the

engine so it does not start and hold the

throttle in the wide-open position when

performing a compression test. An

engine that does not have adequate

compression cannot be properly tuned.

Refer to Chapter Three.

Loading...

Loading...