Engine Management System

•

Make sure to perform work in well-ventilated area and away from any

open fire/flames.

•

Wear Safety glasses

•

To relieve fuel vapor pressure in fuel tank, remove fuel filler cap and then

reinstall it.

•

To relieve pressure in the fuel lines, disconnect the power to the pump, pull the

spark plug boot off the plug and place it away from the plug. Crank the engine to

release the pressure in the lines.

•

After servicing, make sure that the fuel hoses and clamps are connected

according to the hose fitment instructions given in vehicle instruction manual.

•

Check for any fuel leakage.

•

Fill the fuel tank with at least 3 liters of fuel, then turn on the ignition switch to

cycle the pump and prime the system.

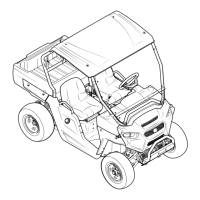

Fuel Module Diagnosis

1

Switch on Ignition key. Fuel Pump

primes for 3 seconds when the

ignition key is ON.

Check for fuel pump running noise

for 3 seconds after ignition key is

pump running?

Go to step 4

Go to step 2

2

Disconnect fuel module coupler.

Check voltage at harness coupler.

Is the voltage within 10-14V?

Go to step 3

circuit from ignition

to fuel module

3

Connect 12V DC power supply

(battery) to fuel module.

Make sure that enough fuel is

available in the fuel tank to avoid

the fuel pump running dry. Is the

fuel pump running?

circuit from fuel

module to ECU

Check ECU

Harness integrity

Check Fuel Pump

4

Check fuel pressure pattern at

injector.

Pull Injector off the manifold and

place it into a suitable catch can

for Gasoline. Crank the engine

over and watch the spray pattern.

Fuel Module

operation is normal

Check for blockage

or a clogged tip of

the injector.

Loading...

Loading...