11.8 SVCREQ 7: Read or Change the Time-of-Day Clock

Use SVCREQ 7 to read or change the time of day clock in the PLC. The data can be

either BCD or ASCII. Either 2-digit-year or 4-digit-year format is available. The function

is successful unless some number other than 0 (read) or 1 (change) is entered for the

requested operation, or an invalid data format is specified, or data is provided in an

unexpected format.

11.8.1 Parameter Block Format for SVCREQ 7

For the date/time functions, the length of the parameter block depends on the data format.

The data block is either BCD or ASCII. BCD format requires 6 words; packed ASCII

requires 12 words (13 words for 4-digit year). For both data types:

• Hours are stored in 24-hour format.

• Day of the week is a numeric value from 1 (Sunday) to 7 (Saturday).

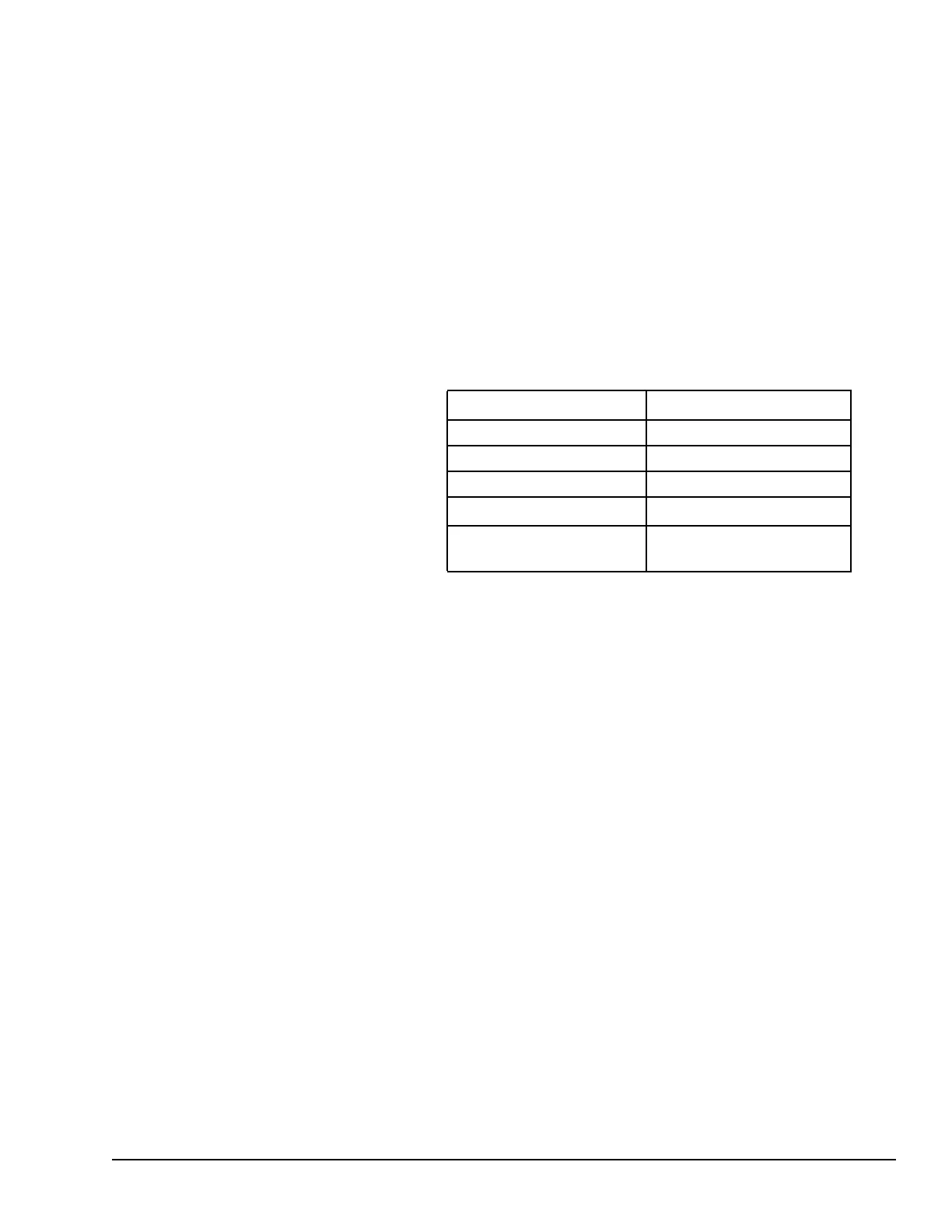

2-Digit Year Format 4-Digit Year Format

address

0 = read time and date 0 = read time and date

1 = set time and date 1 = set time and date

address + 1

1 = BCD format 81h = BCD format

3 = packed ASCII format 83h = packed ASCII format

address + 2 to

end

data data

Words 3 to the end of the parameter block contain output data returned by a read function,

or new data being supplied by a change function. In both cases, format of these data

words is the same. When reading the date and time, words (address + 2) to the end of the

parameter block are ignored on input.

The Service Request Function GFK-1503E User Manual 205

For public disclosure