GENERAL ENGINE MECHANICAL 6A – 35

3. Use a syringe to apply the solution to the surface to be

inspected.

Hold the surface to be inspected perfectly horizontal to

prevent the solution from running.

NOTE:

Do not allow the solution to come in contact with the

oil ports and their surrounding area.

Testing

1. Wait for thirty to forty seconds.

If there is no discoloration after thirty or forty seconds,

the crankshaft is usable.

If discoloration appears (the surface being tested will

become the color copper), the crankshaft must be

replaced.

2. Steam clean the crankshaft surface immediately after

completing the test.

NOTE:

The ammonium cupric chloride solution is highly

corrosive. Because of this, it is imperative that the

surfaces being tested be cleaned immediately after

completing the test.

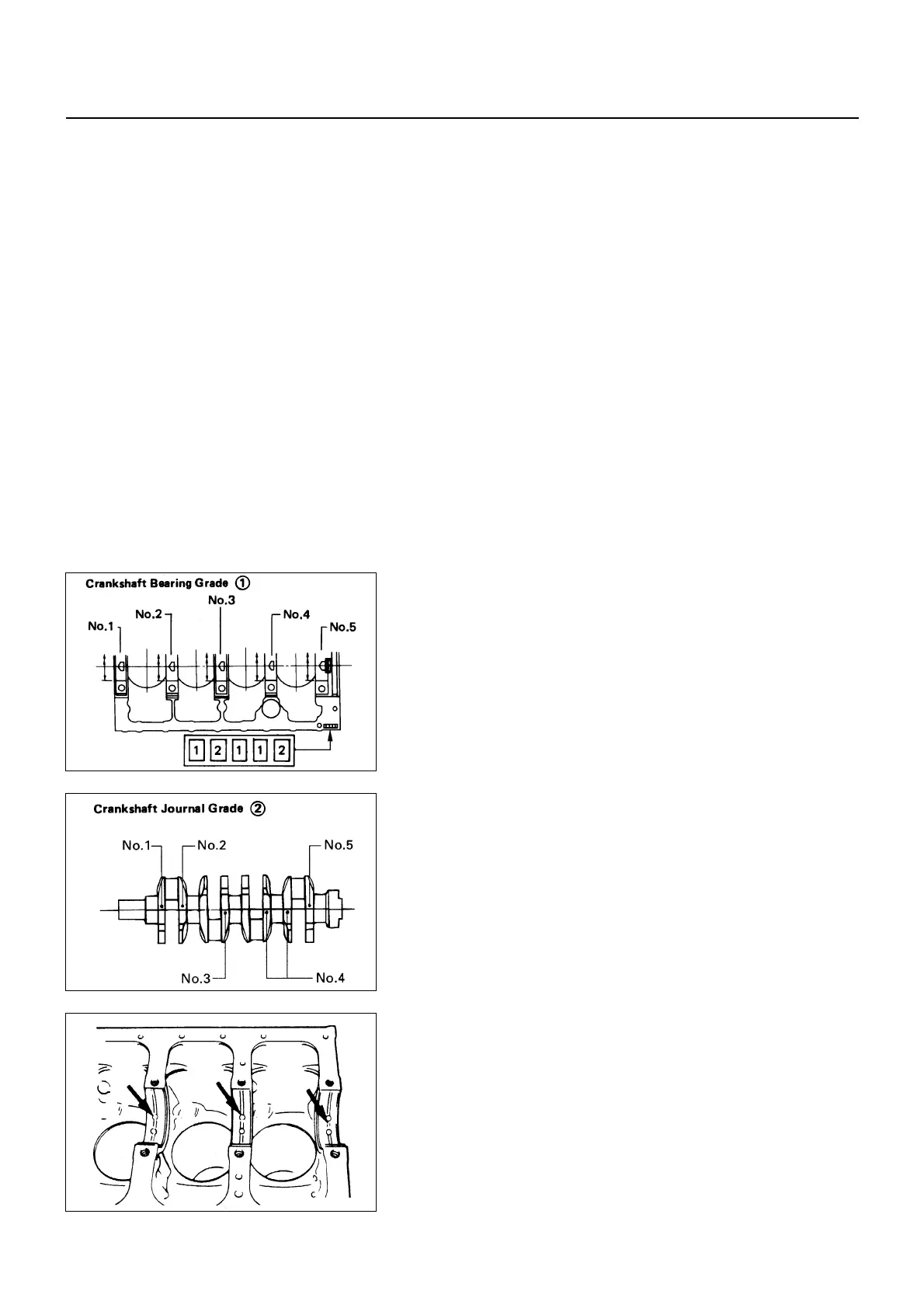

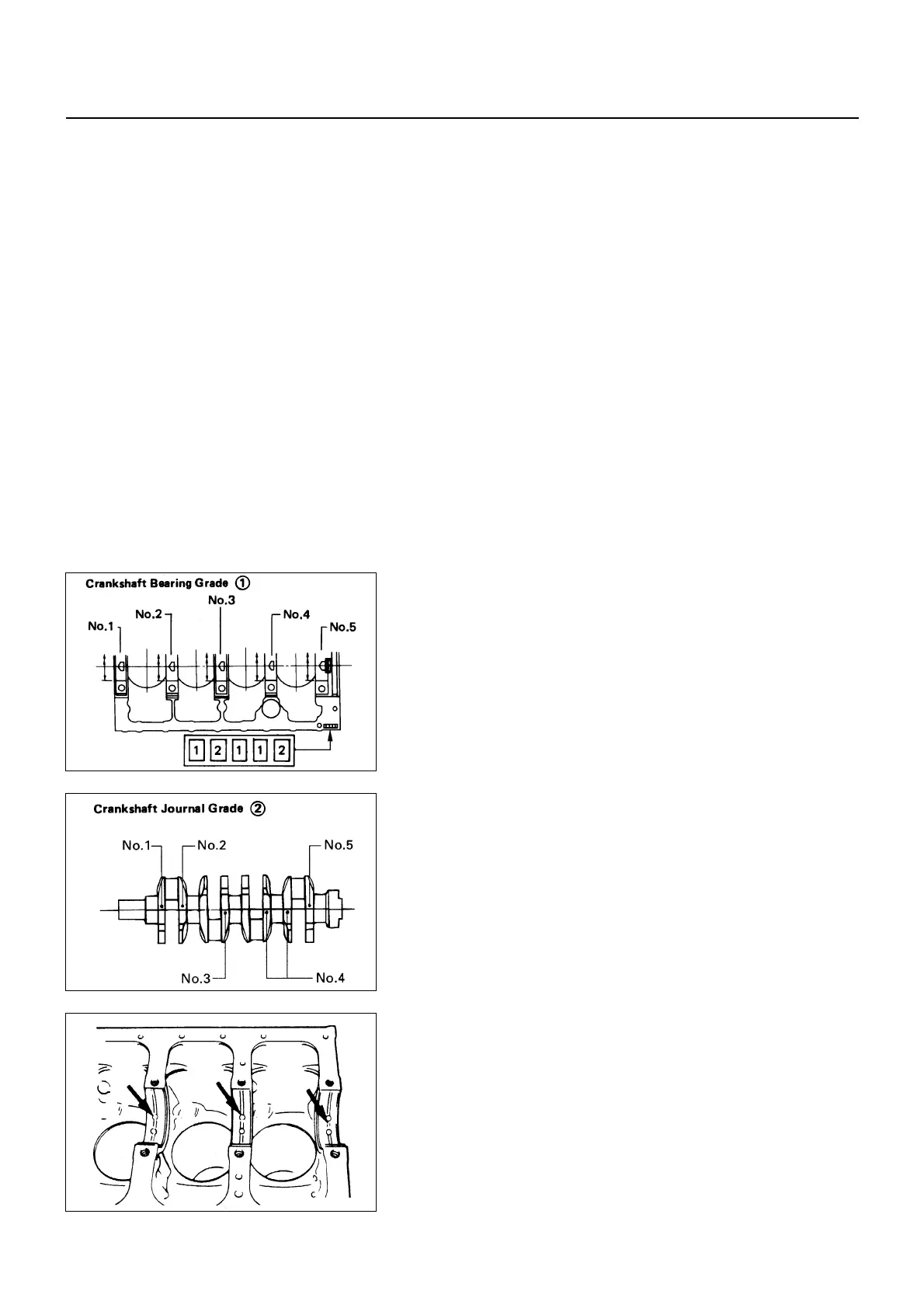

CRANKSHAFT BEARING SELECTION

When installing new crankshaft bearings or replacing old

bearings, refer to the selection table.

NOTE:

Please note that some Crankshaft No. 4 journals made

during a limited production period have their number

(No. 4) marked on either their front or rear side of

webs as shown below.

NOTE:

Although all upper journal bearings (cylinder body

side) have oil grooves and holes, all lower bearings

(bearing cap side) have no groove and hole.

Play close attention to the distinction during the

installation procedure.

6A-35-1.tif

6A-35-2.tif

6A-35-3.tif

Loading...

Loading...