ENGINE FUEL 6C - 11

CAUTION

• If the needle valve does not slide smoothly repair or

replace with a new nozzle assembly.

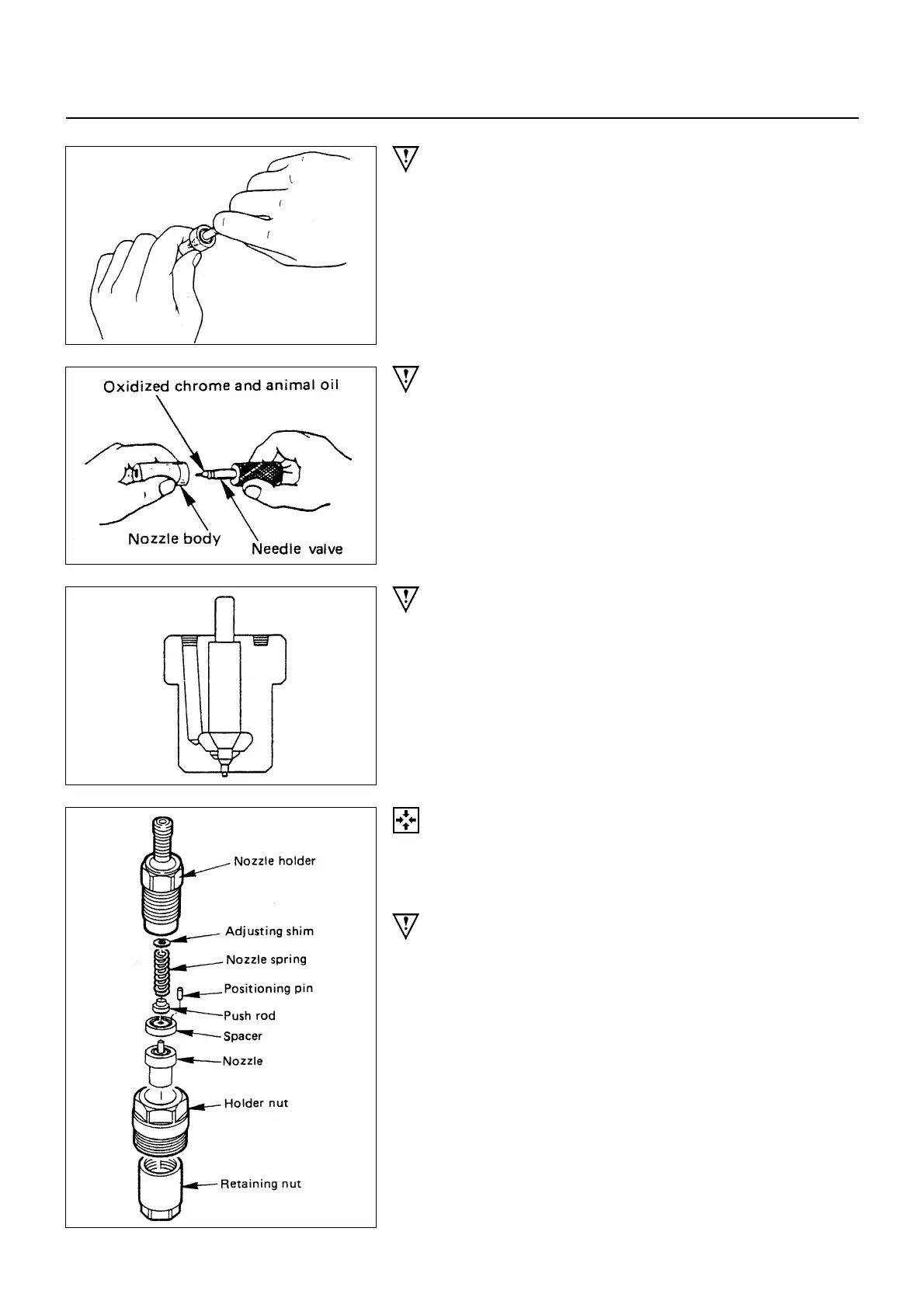

Nozzle lapping procedure

• Apply thinly a compound (Chrome oxide kneaded with

an animal oil) to the seat of needle valve and lap.

CAUTION

• Excess compound may cause worn needle valve, and

be sure to wash out the compound after lapping.

Nozzle body & needle

• Check nozzle body and end for seizure.

If significantly seized, replace as a nozzle assembly

basis. Also replace as a nozzle assembly basis, if

needle valve end is deformed or seized.

CAUTION

• If either nozzle body or needle valve is faulty, replace

with a new nozzle assembly.

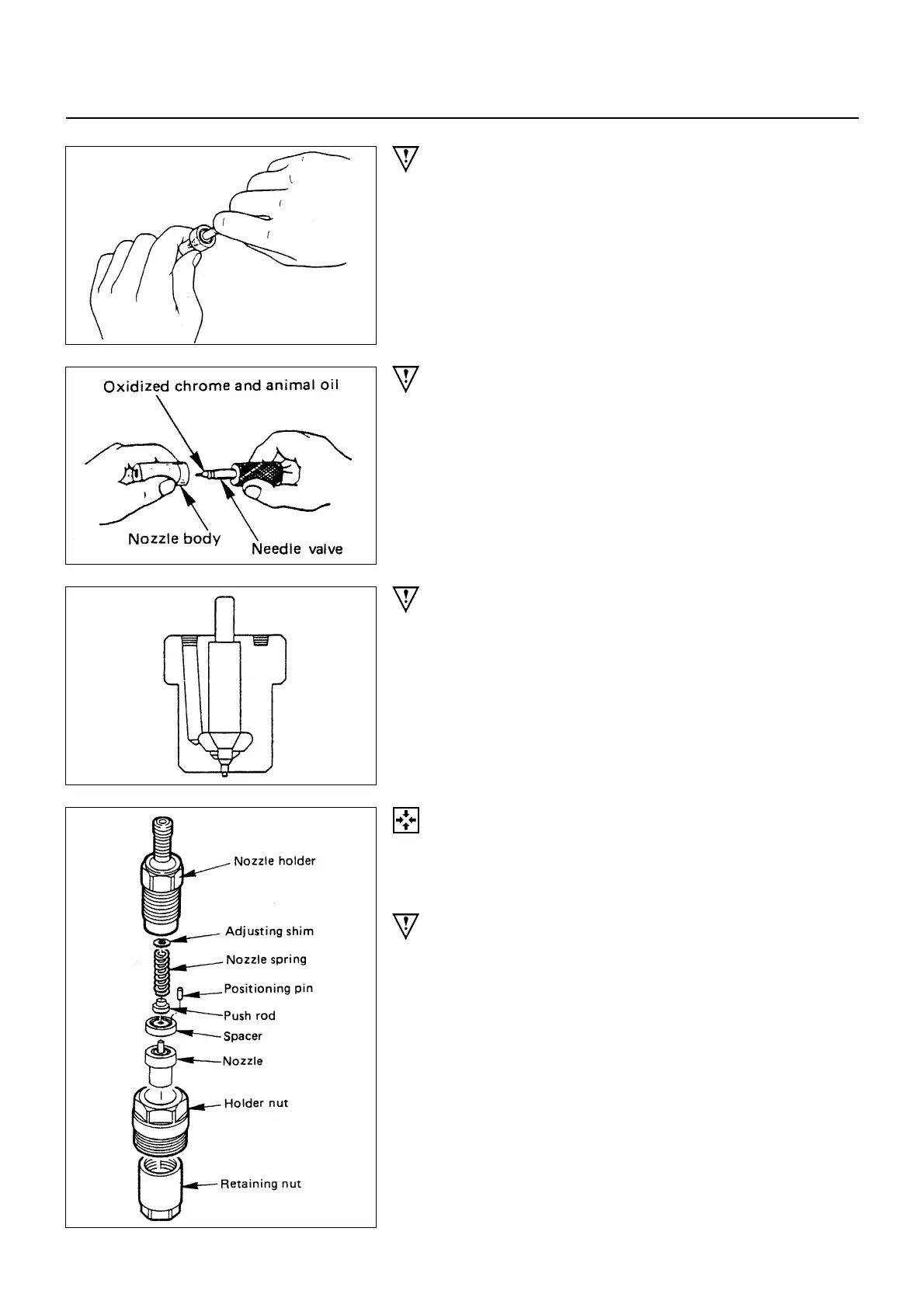

REASSEMBLY (4JG2 Engine)

To reassemble, follow the removal steps in the reverse order,

noting the following point.

CAUTION

• Be careful to fit spacer because positioning pins are

set off.

6C-10-1.tif

6C-10-2.tif

6C-10-3.tif

6C-10-4.tif

Loading...

Loading...