GENERAL ENGINE MECHANICAL 6A – 59

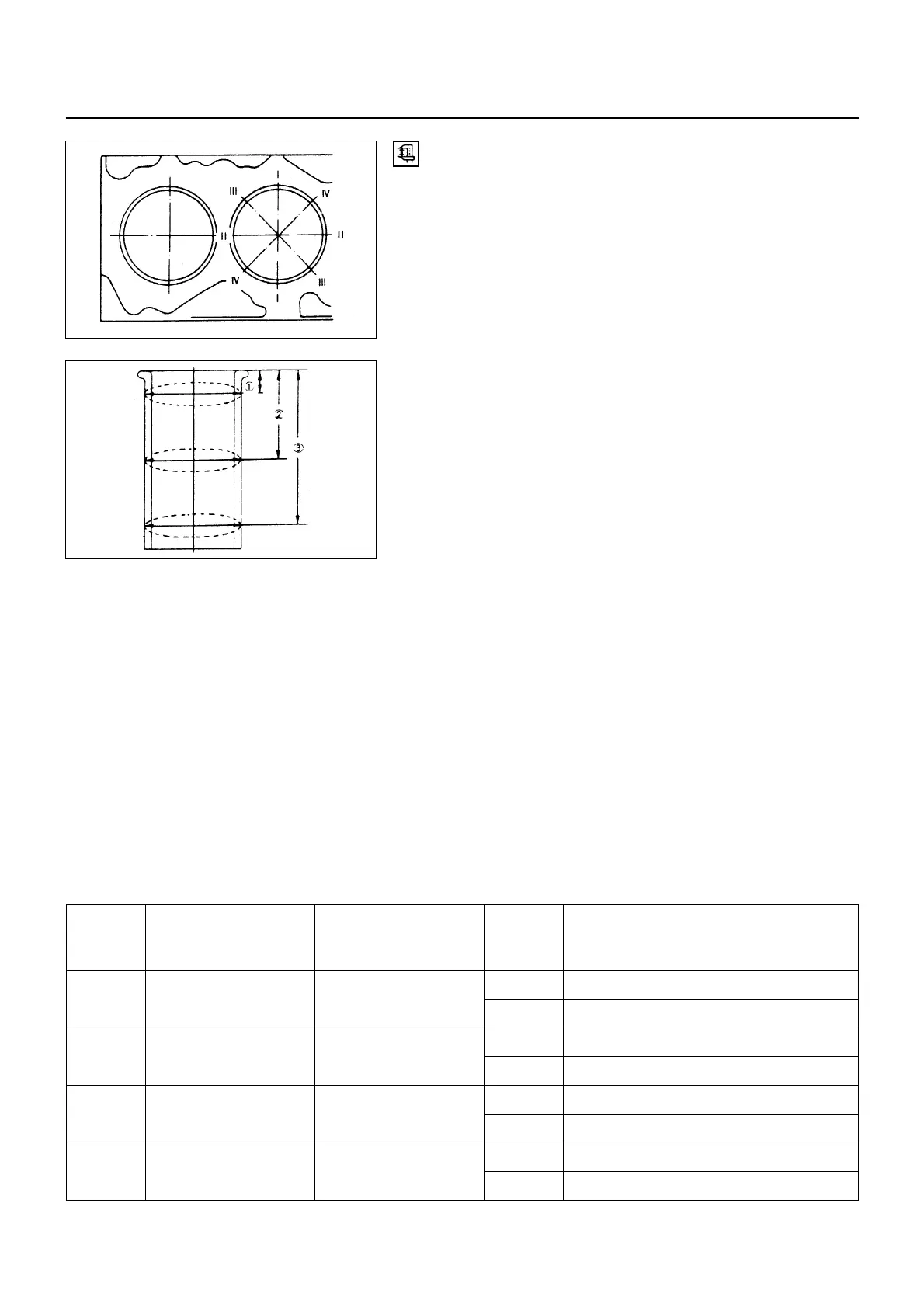

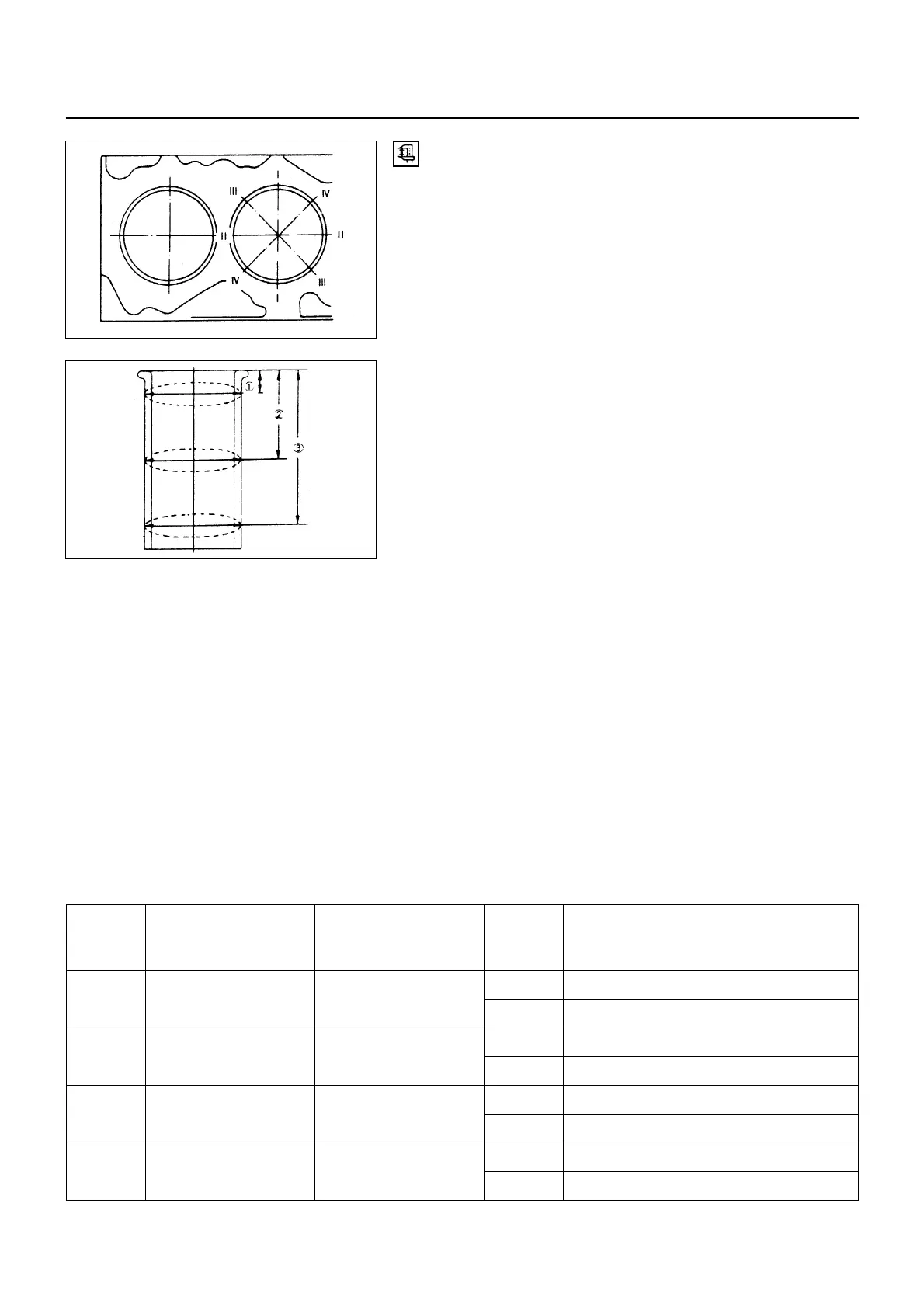

Cylinder Body Bore Measurement

1) Take measurements at measuring point (A) across

positions

!

-

!

,

"

-

"

,

#

-

#

, and

$

-

$

.

Measuring Point (A) 98mm (3.86 in).

2) Calculate the average value of the four measurements

to determine the correct cylinder grade.

3) Consult the following table with the resultant diameter

for the correct liner application.

Selection method of cylinder liner and piston grade for

service parts.

The production line stamped cylinder liner grade on the

top of cylinder body, the cylinder liner outside diameter

grade 1, 2, 3, 4.

If you find cylinder liner outside diameter grade 1 and

piston outside diameter B on the cylinder body or result of

measurement for each parts, you will select service parts

grade for cylinder liner 1, AX grade and for piston AX

grade.

The stamping grade code on the service parts are;

For cylinder liner grade stamped on the outside of cylinder

liner.

For piston grade stamped on the head of piston.

4JB1 / 4JB1T / 4JB1TC mm (in)

Liner

outside

Grade

Cylinder bore

diameter average

Liner outside

diameter

Liner

bore

Grade

Service liner bore measurement

AX 93.035 (3.6628) - 93.050 (3.6634)

1

95.001 - 95.010

(3.7402 - 3.7406)

95.011 - 95.020

(3.7406 - 3.7409)

CX 93.051 (3.6634) - 93.066 (3.6640)

AX 93.035 (3.6628) - 93.050 (3.6634)

2

95.011 - 95.020

(3.7406 - 3.7409)

95.021 - 95.030

(3.7410 - 3.7413)

CX 93.051 (3.6634) - 93.066 (3.6640)

AX 93.035 (3.6628) - 93.050 (3.6634)

3

95.021 - 95.030

(3.7410 - 3.7413)

95.031 - 95.040

(3.7414 - 3.7417)

CX 93.051 (3.6634) - 93.066 (3.6640)

AX 93.035 (3.6628) - 93.050 (3.6634)

4

95.031 - 95.040

(3.7414 - 3.7417)

95.041 - 95.050

(3.7418 - 3.7421)

CX 93.051 (3.6634) - 93.066 (3.6640)

6A-59-1.tif

6A-59-2.tif

Loading...

Loading...