TURBOCHARGER 6G – 7

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Minor servicing operations are described in this Section.

Contact the nearest IHI SERVICE FACILITY for major repairs

and maintenance.

Refer to “IHI SERVICE NETWORK” at the end of this Section.

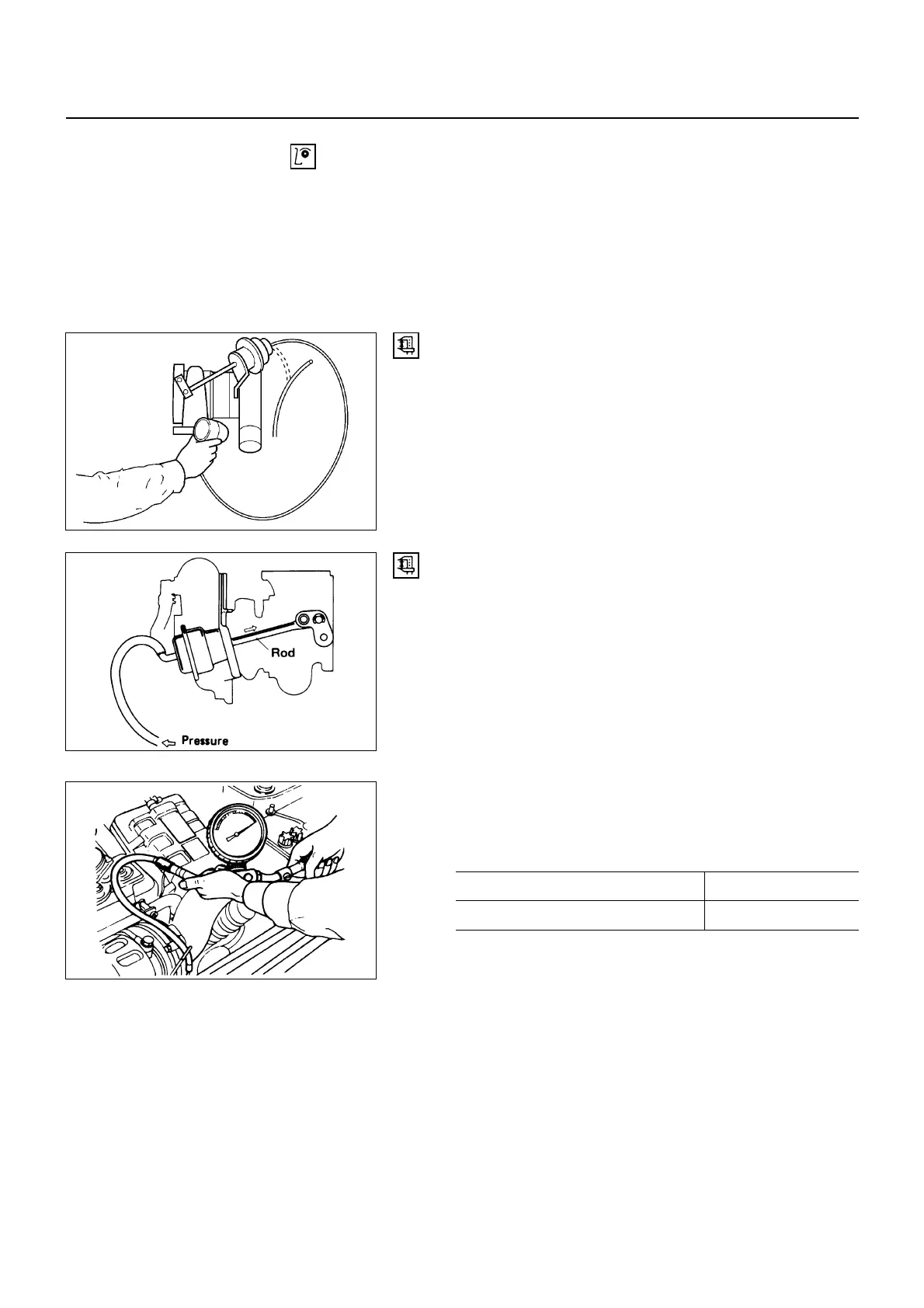

Turbocharger pressure check

(1) Remove the waste gate control chamber connecting hose.

(2) Connect the pressure gauge.

(3) Start the engine and gradually increase the engine speed

(the vehicle must be stationary with no load applied to the

engine).

(4) Check to see that turbocharger pressure rises to

approximately 500 mmHg.

Pressure Gauge : 5-8840-0075-0

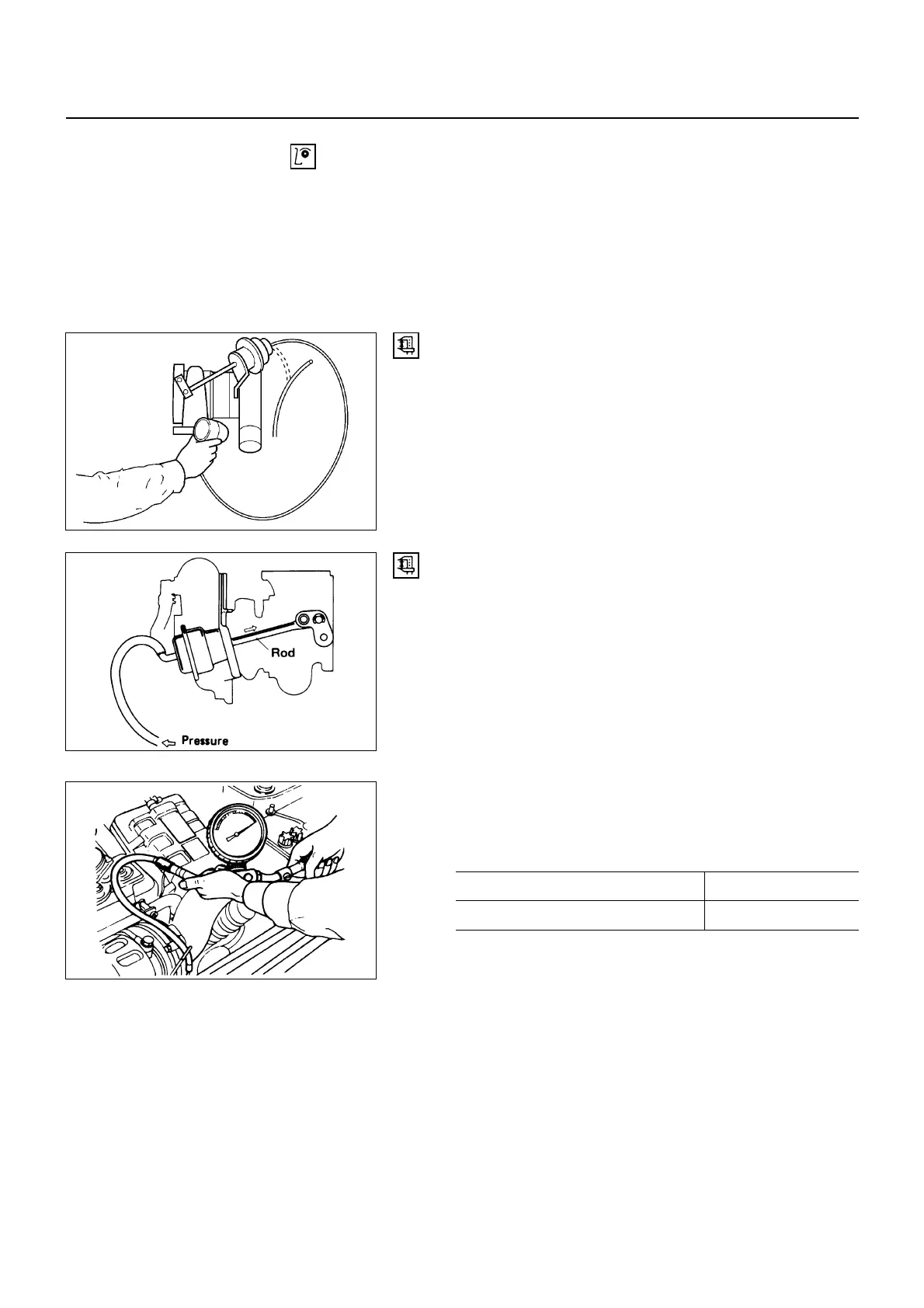

Waste gate operation check

(1) Remove the hose between the waste gate control

chamber and the intake pipe.

(2) Connect the pressure gauge.

(3) Check to see that the rod begins to move when a pressure

of approximately 665 mmHg is applied to the waste gate,

control chamber.

NOTE:

Do not apply a pressure greater than 1467mmHg (196 kPa)

to the waste gate during this check.

(4) Check to see the pressure required to move the control

rod 2 mm is within the limits shown below.

Control Rod Operating Pressure mmHg (kPa)

4JBIT (IHI RHB5) 898 ± 36 (120 ± 4.8)

4JBITC (IHI RHF4) 815 ± 33 (109 ± 4.4)

036HY00002.tif

6G-7-2.tif

6G-7-3.tif

Loading...

Loading...