6A – 60 GENERAL ENGINE MECHANICAL

4JG2 mm (in)

Liner

outside

Grade

Cylinder bore

diameter average

Liner outside

diameter

Liner

bore

Grade

Service liner bore measurement

AX 95.435 (3.7573) - 95.450 (3.7579)

1

97.001 - 97.010

(3.8189 - 3.8193)

97.011 - 97.020

(3.8193 - 3.8197)

CX 95.451 (3.7579) - 95.466 (3.7585)

AX 95.435 (3.7573) - 95.450 (3.7579)

2

97.011 - 97.020

(3.8193 - 3.8197)

97.021 - 97.030

(3.8197 - 3.8201)

CX 95.451 (3.7579) - 95.466 (3.7585)

AX 95.435 (3.7573) - 95.450 (3.7579)

3

97.021 - 97.030

(3.8197 - 3.8201)

97.031 - 97.040

(3.8201 - 3.8205)

CX 95.451 (3.7579) - 95.466 (3.7585)

AX 95.435 (3.7573) - 95.450 (3.7579)

4

97.031 - 97.040

(3.8201 - 3.8205)

97.041 - 97.050

(3.8205 - 3.8209)

CX 95.451 (3.7579) - 95.466 (3.7585)

NOTE:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will

result in engine failure. Always measure the cylinder

bore and select the correct piston grade.

Cylinder liner kit clearances are preset. However, the

cylinder liner installation procedure may result in

slight decreases in cylinder liner clearances. Always

measure the cylinder liner clearance after installation

to be sure that it is correct.

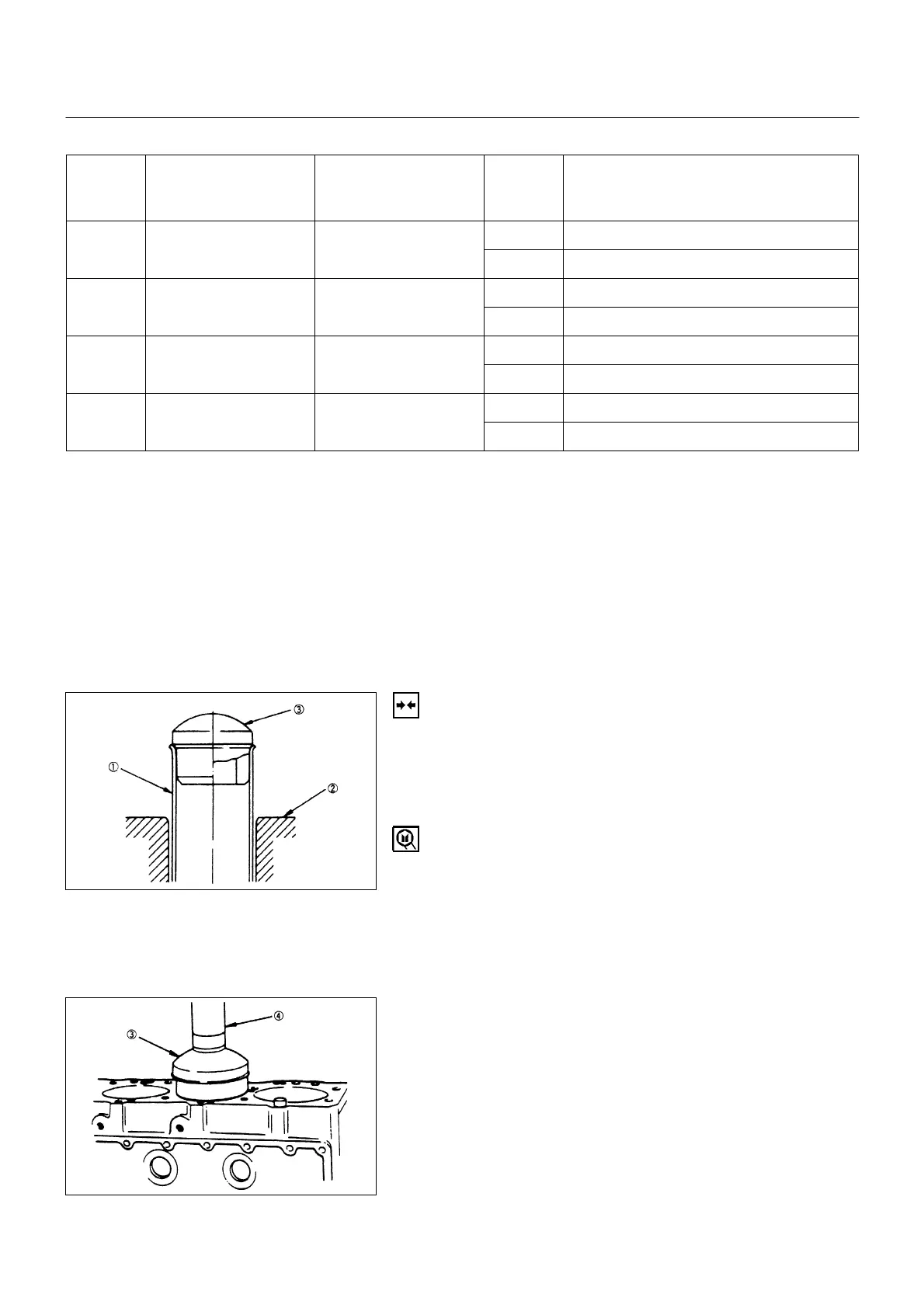

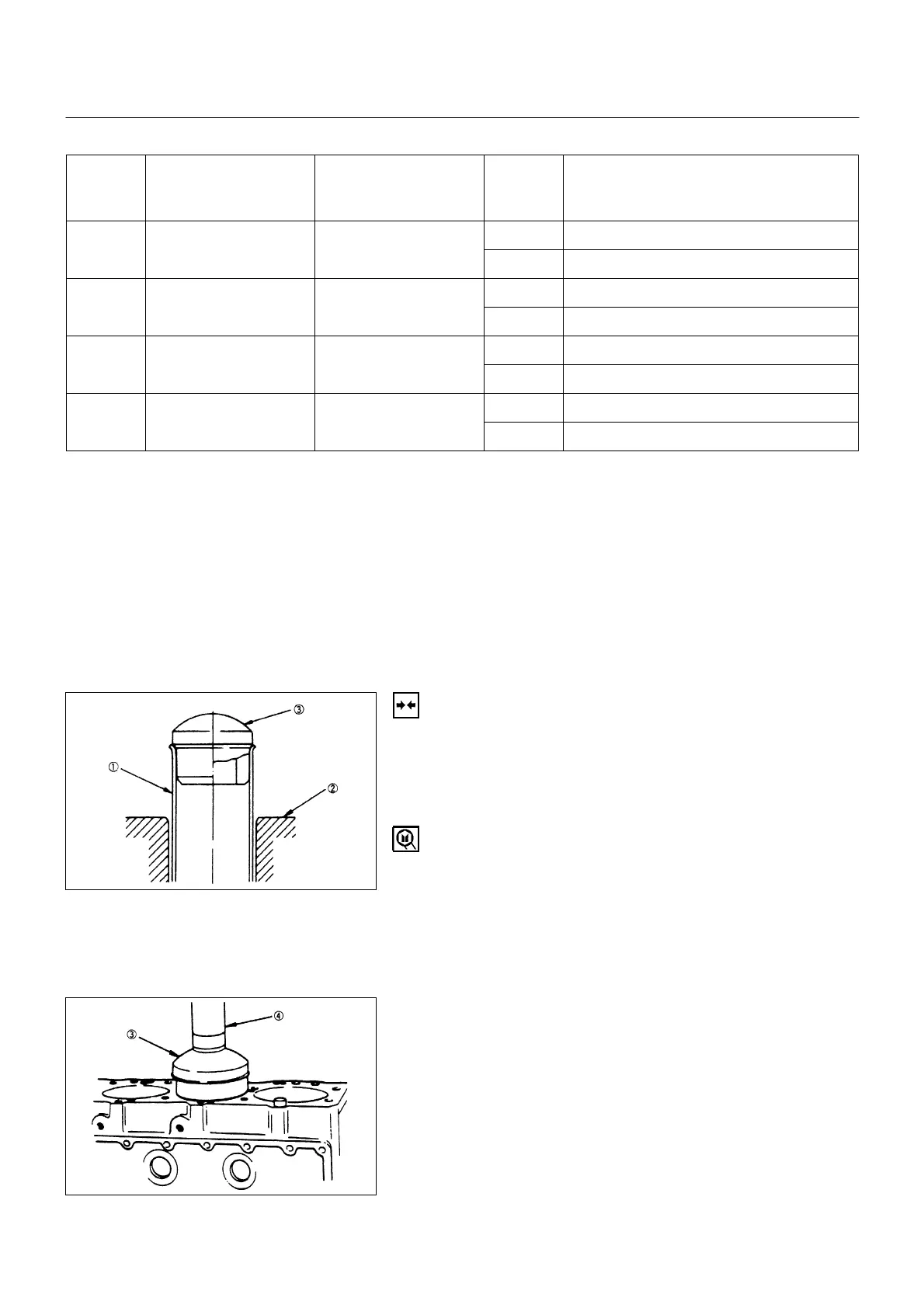

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool.

1) Use new kerosene or diesel oil to thoroughly clean

the cylinder liners and bores.

2) Use compressed air to blow-dry the cylinder liner

and bore surfaces.

Cylinder Liner Installer: 5-8840-2313-0 (4JG2)

: 5-8840-2040-0 (4JB1 / 4JB1T/

4JB1TC)

NOTE:

All foreign material must be carefully removed from

the cylinder liner and the cylinder bore before

installation.

3) Insert the cylinder liner

!

into the cylinder body

"

from the top of the cylinder body.

6A-60-1.tif

6A-60-2.tif

Loading...

Loading...