GENERAL ENGINE MECHANICAL 6A – 57

7. Piston Cooling Oil Pipe

8. Piston and Connecting Rod

9. Flywheel

10. Cylinder Block Rear Plate

11. Crankshaft Rear Oil Seal

12. Main Bearing Cap

13. Crankshaft

14. Camshaft

15. Tappet

16. Cylinder Block

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

1. Remove the gasket and any other material adhering

the upper surface of the cylinder block.

Be very careful not to allow any material to accidental

drop into the cylinder block.

Be very careful not to scratch the cylinder block.

2. Carefully remove the oil pump, Rear Seal retainer and

oil pan installation surface seal.

3. Wipe the cylinder block clean.

Cylinder Liner Projection Inspection

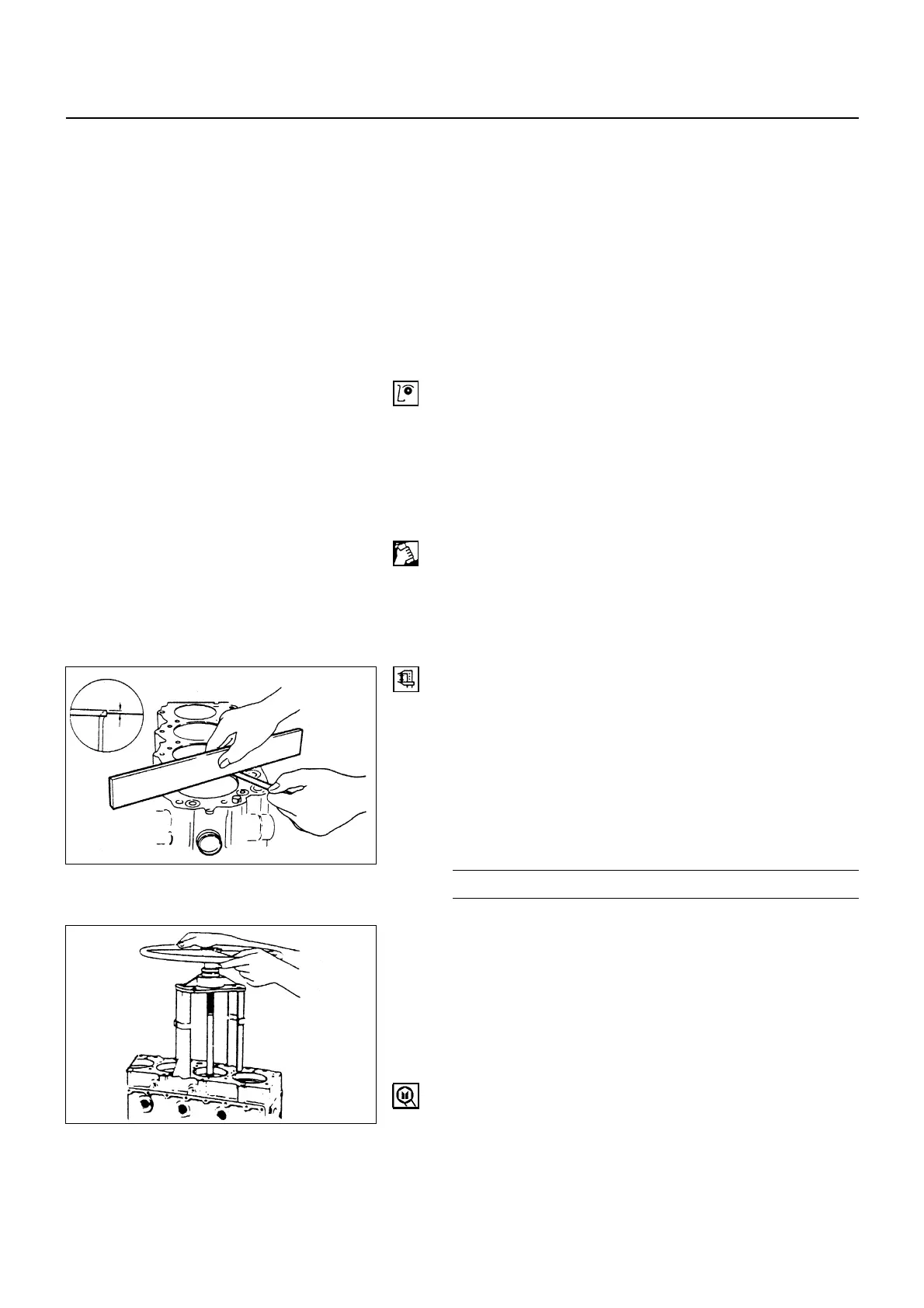

1. Hold a straight edge

!

along the top edge of the

cylinder liner to be measured.

2. Use a feeler gauge

"

to measure each cylinder line

projection.

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed

0.03 mm (0.0012 in).

Standard mm (in)

0.0 - 0.1 (0.0000 - 0.0039)

Flatness

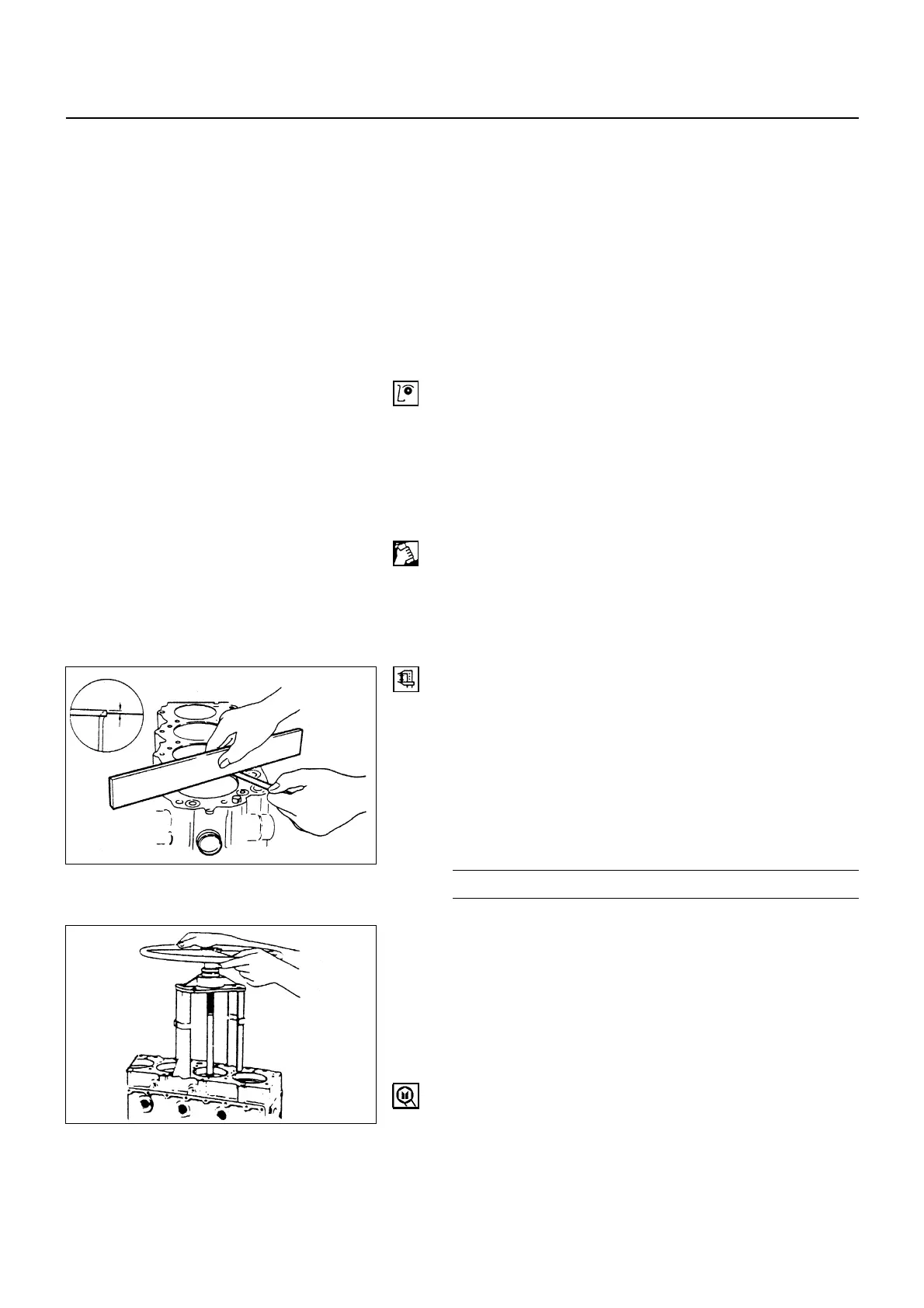

1. Remove the cylinder body dowel.

2. Set the cylinder liner remover to the cylinder liner.

3. Check that the remover shaft ankle is firmly gripping

the cylinder liner bottom edge.

4. Slowly turn the remover shaft handle counterclockwise

to pull the cylinder liner free.

Cylinder Liner Remover Ankle: 5-8840-2304-0 (4JG2)

5-8840-2039-0

(4JB1/4JB1T/4JB1TC)

NOTE:

Take care not to damage the cylinder body upper

during the cylinder liner removal procedure.

6A-57-1.tif

6A-57-2.tif

Loading...

Loading...