6A – 20 GENERAL ENGINE MECHANICAL

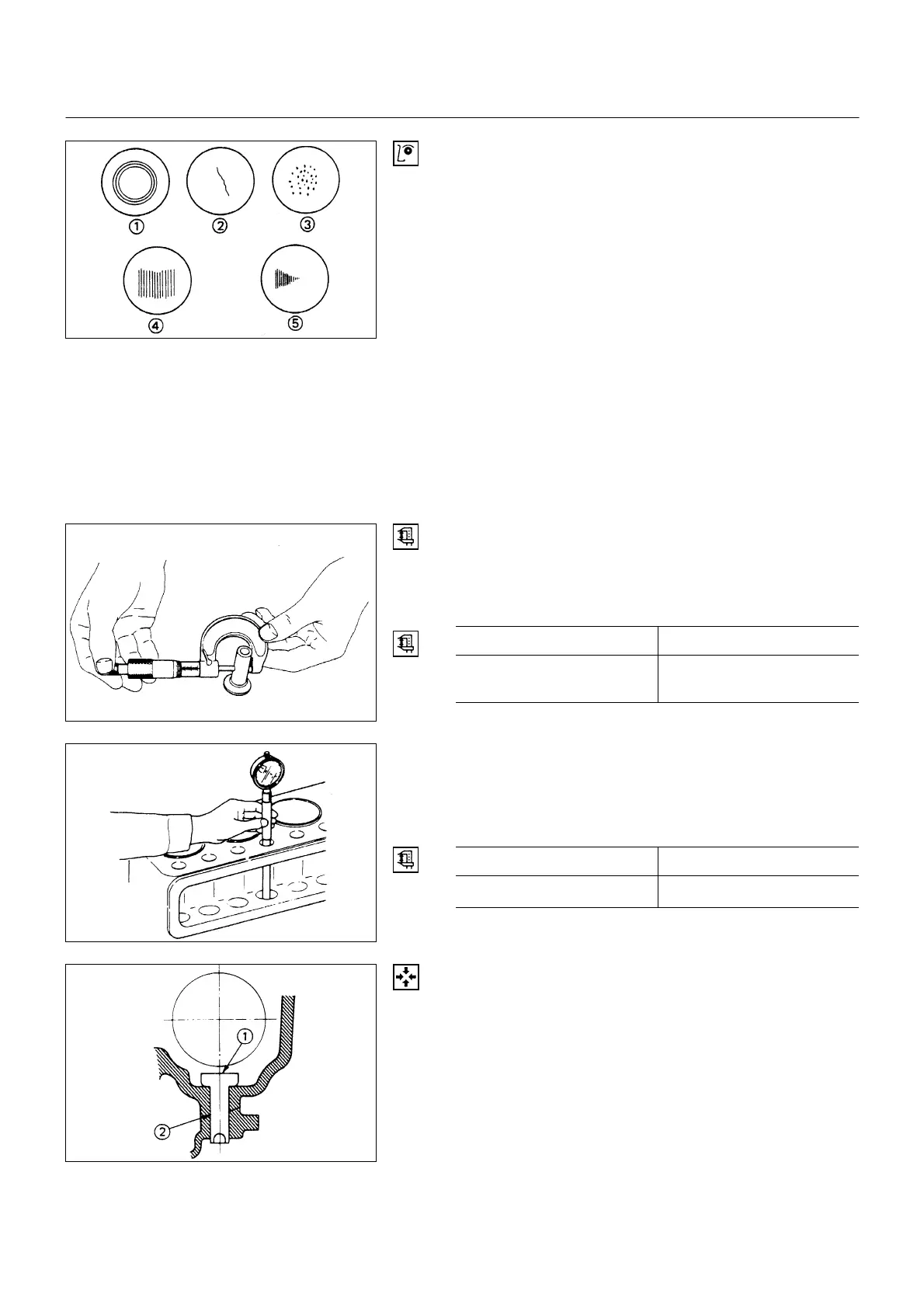

TAPPET

Visually inspect the tappet camshaft contact surfaces for

pitting, cracking, and other abnormal conditions. The

tappet must be replaced if any of these conditions are

present.

Refer to the illustration at the left.

!

Normal contact

"

Cracking

#

Pitting

$

Irregular contact

%

Irregular contact

NOTE:

The tappet surfaces are spherical. Do not attempt to

grind them with an oil stone or similar tool in an effort

to repair the tappet. If the tappet is damaged, it must

be replaced.

Tappet Outside Diameter

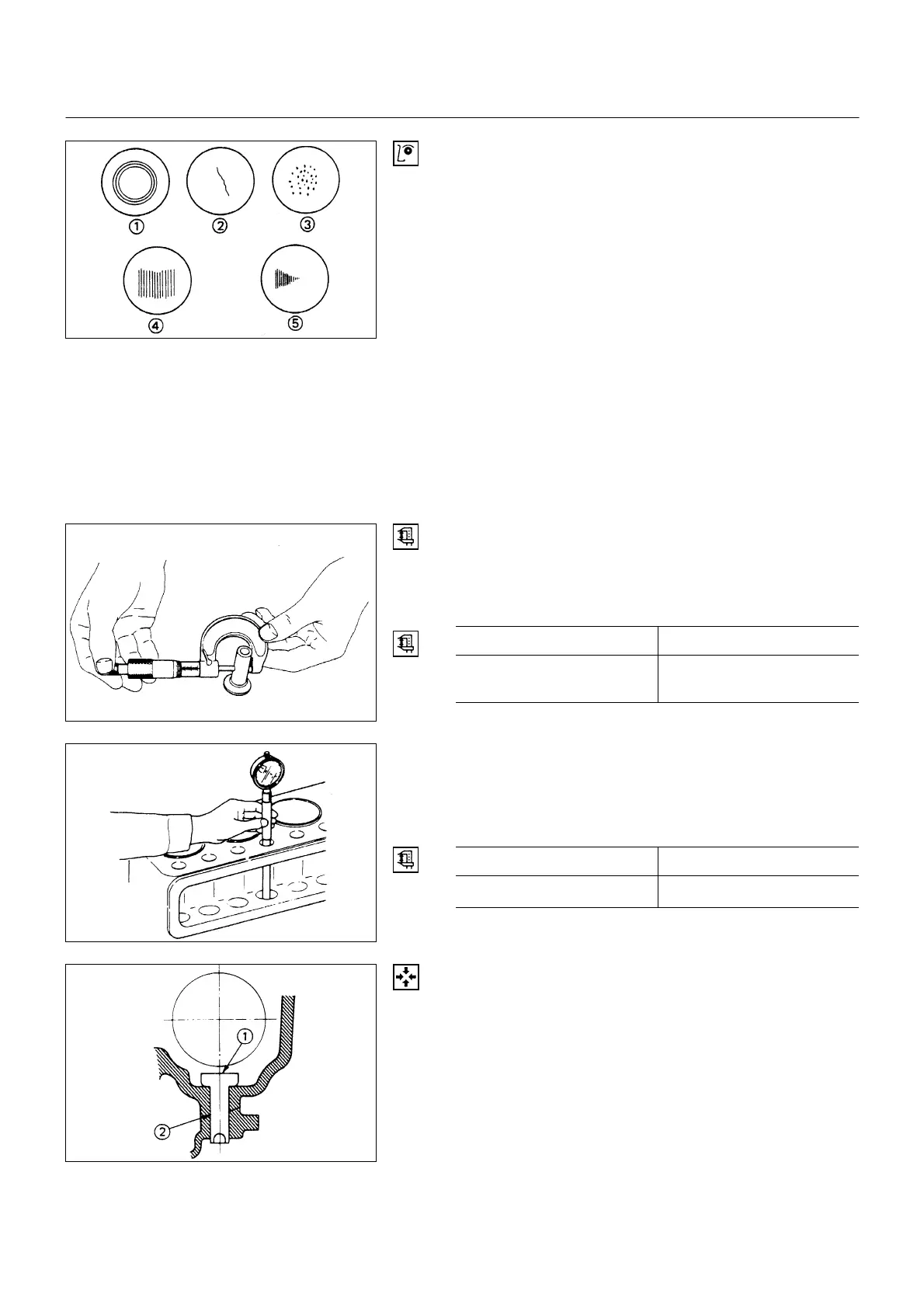

1. Measure the tappet outside diameter with a

micrometer. If the measured value is less than the

specified limit, the tappet must be replaced.

Tappet Outside Diameter mm (in)

Standard Limit

12.97 - 12.99

(0.510 - 0.511)

12.95 (0.509)

2. Measure the inside diameter tappet on the cylinder

block and calculate the clearance.

If the clearance exceeds the limit, replace tappet

or/and cylinder block.

Tappet and Cylinder Body Clearance mm (in)

Standard Limit

0.03 (0.001) 0.10 (0.004)

REASSEMBLY

9. Tappet

1) Apply a coat of engine oil to the tappet 1 and the

cylinder body tappet insert holes 2.

2) Locate the position mark applies at disassembly (if the

tappet is to be reused).

NOTE:

The tappet must be installed before the camshaft.

6A-20-1.tif

6A-20-2.tif

6A-20-3.tif

6A-20-4.tif

Loading...

Loading...