ENGINE FUEL 6C - 25

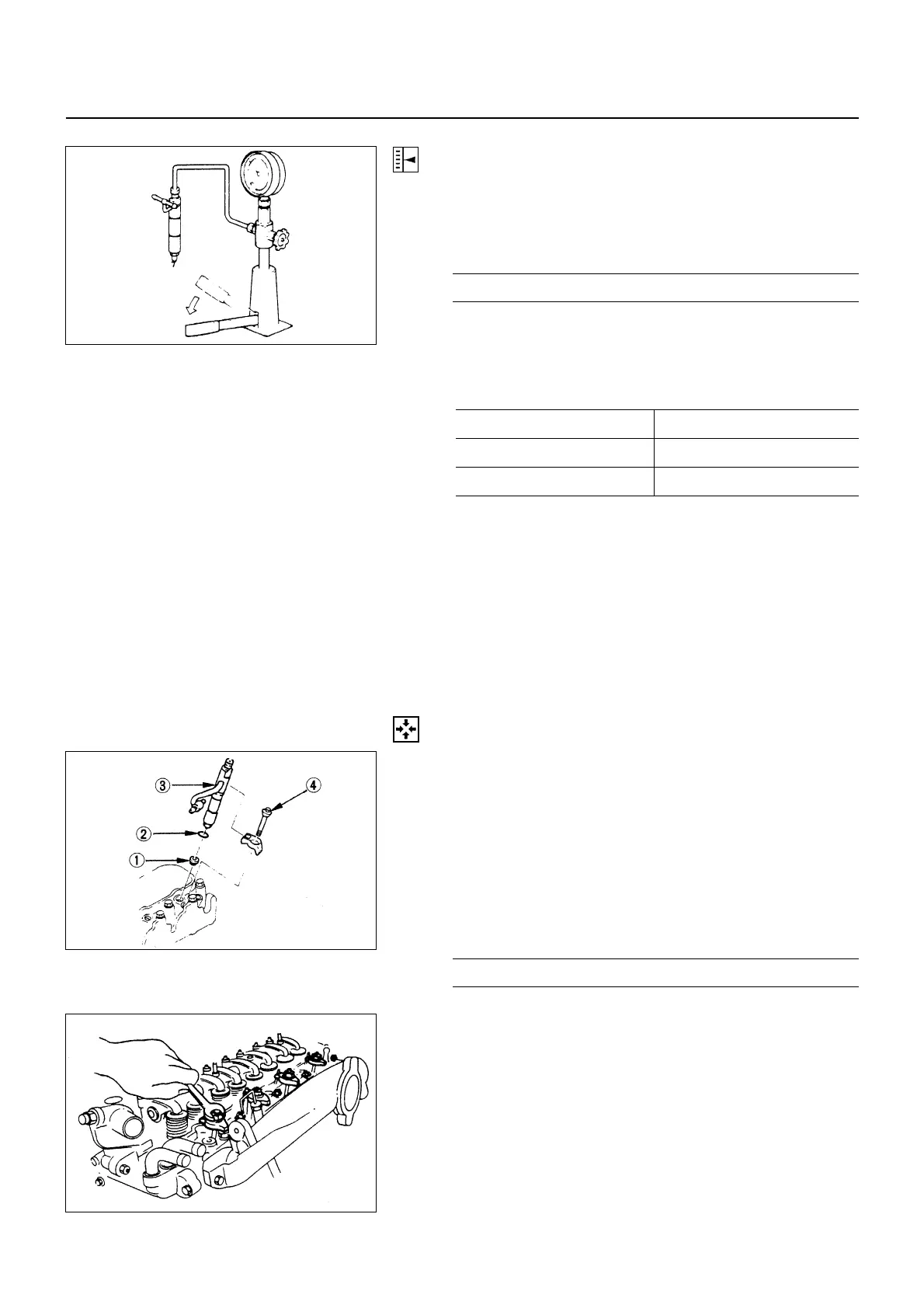

Injection Nozzle Adjustment

1) Attach the injection nozzle holder to the injection

nozzle tester.

2) Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

kPa (kg/cm

2

/psi)

18,142 (185/2630)

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number of

adjusting shims to adjust it.

Adjusting Shim Availability mm (in)

Range 0.50 - 1.50 (0.02 - 0.06)

Increment 0.025 (0.001)

Total No. of Shims 40

Removing or installing one shim will increase of decrease

the nozzle opening pressure approximately 369.46 kPa

(3.77 kg/cm

2

/53.6 psi).

WARNING:

TEST FLUID FROM THE INJECTION NOZZLE WILL SPRAY

OUT UNDER GREAT PRESSURE. IT CAN EASILY

PUNCTURE A PRESON'S SKIN. KEEP YOUR HANDS

AWAY FROM THE INJECTION NOZZLE TESTER AT ALL

THE TIMES.

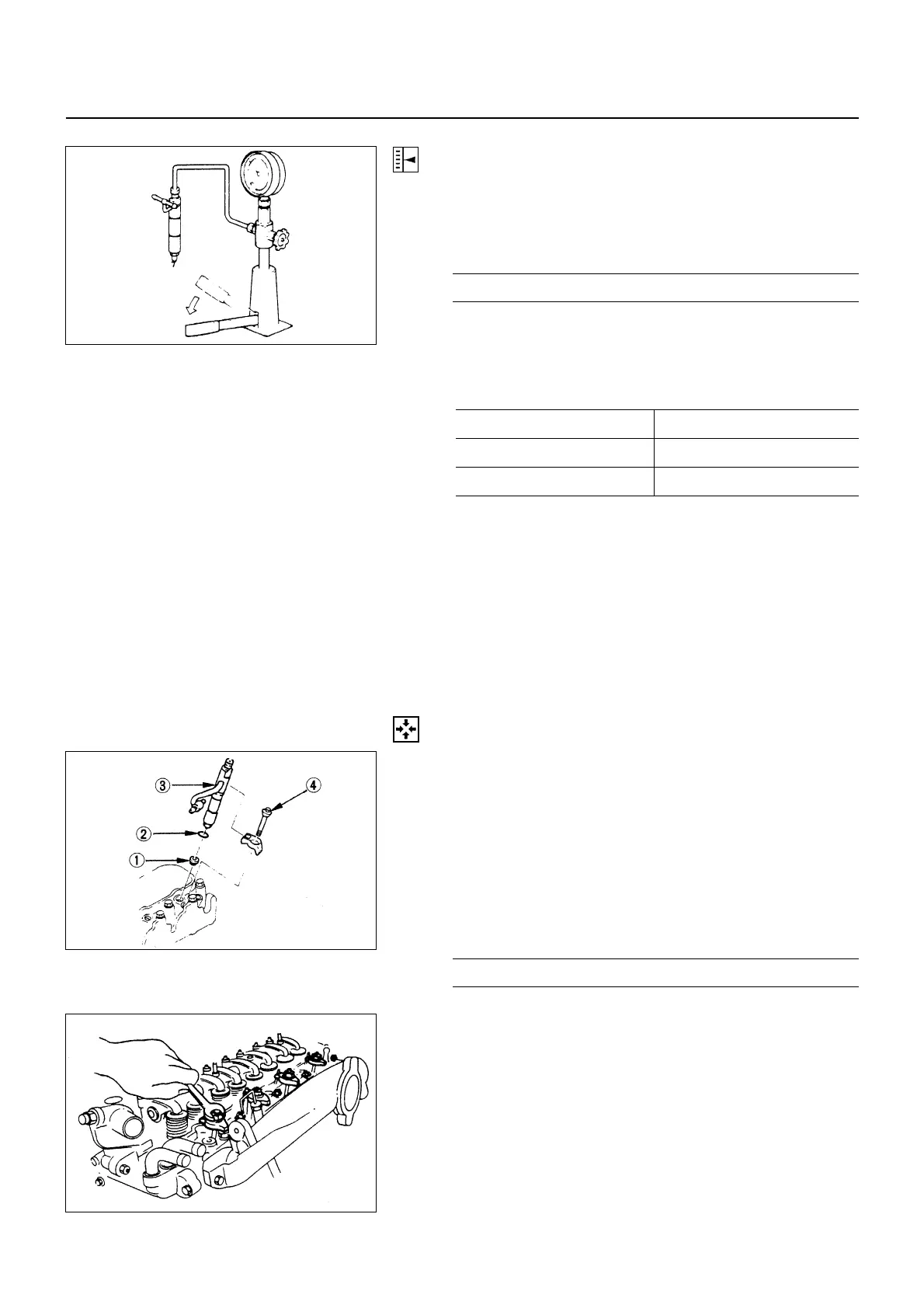

INSTALLATION (4JB1/4JB1T Engine)

3. Injection Nozzle

1) Install the injection nozzle gasket

!

and the O-ring

"

to the injection nozzle holder

#

.

Be sure that the O-ring fits snugly in the injection

nozzle groove.

2) Apply engine oil to the cylinder head nozzle holder

hole.

3) Install the nozzle holder together with the nozzle holder

bracket

$

to the cylinder head.

N∙m (Kg∙m/lb∙ft)

37 (3.8/27)

2. Leak Off Hose

1. Injection Pipe

6C-24-1.tif

6C-24-2.tif

6C-24-3.tif

Loading...

Loading...