ENGINE FUEL 6C - 13

INSTALLATION (4JG2 Engine)

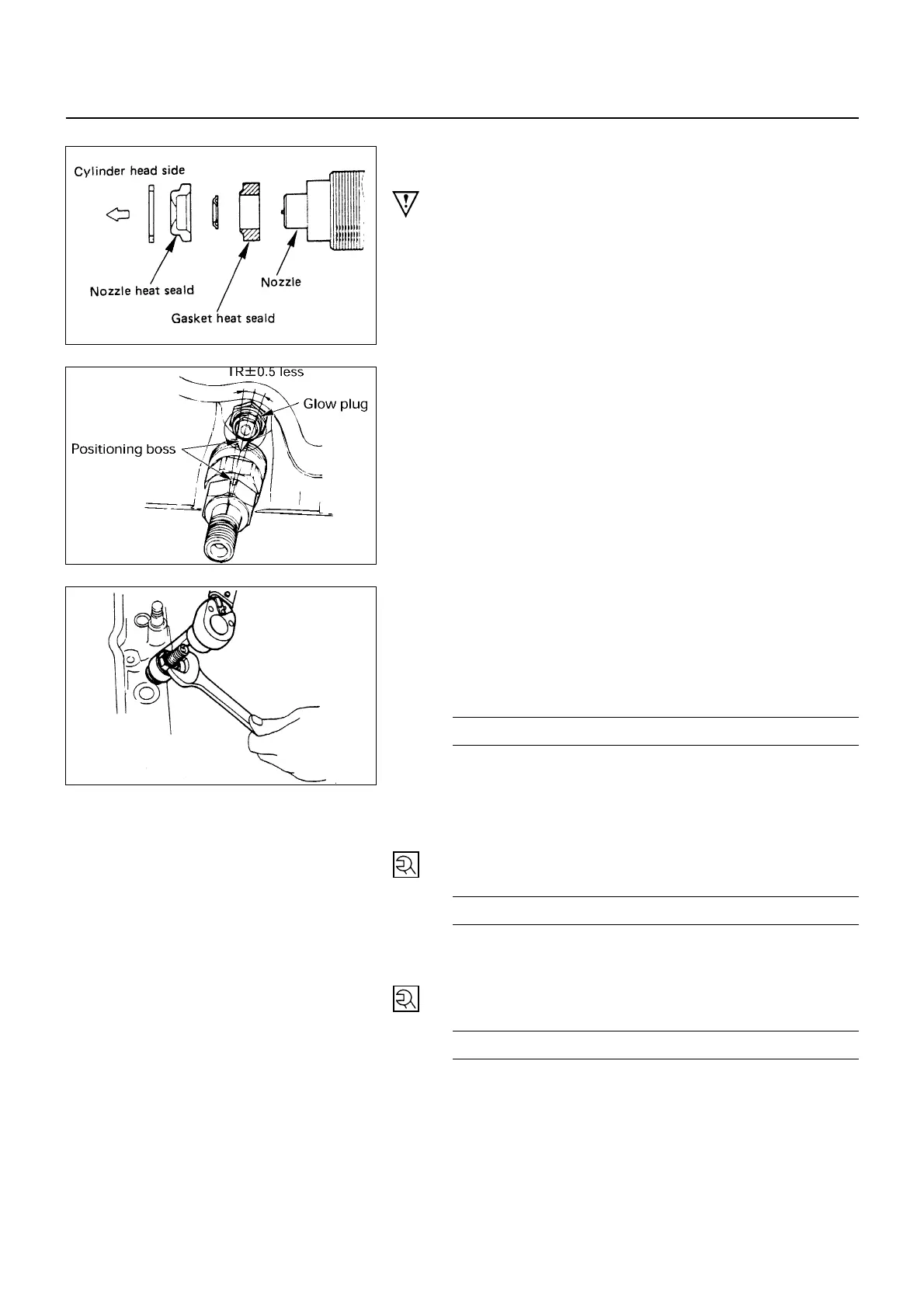

CAUTION

• Nozzle and assembling should be as illustrated.

• Use new heat shield and new corrugated washer.

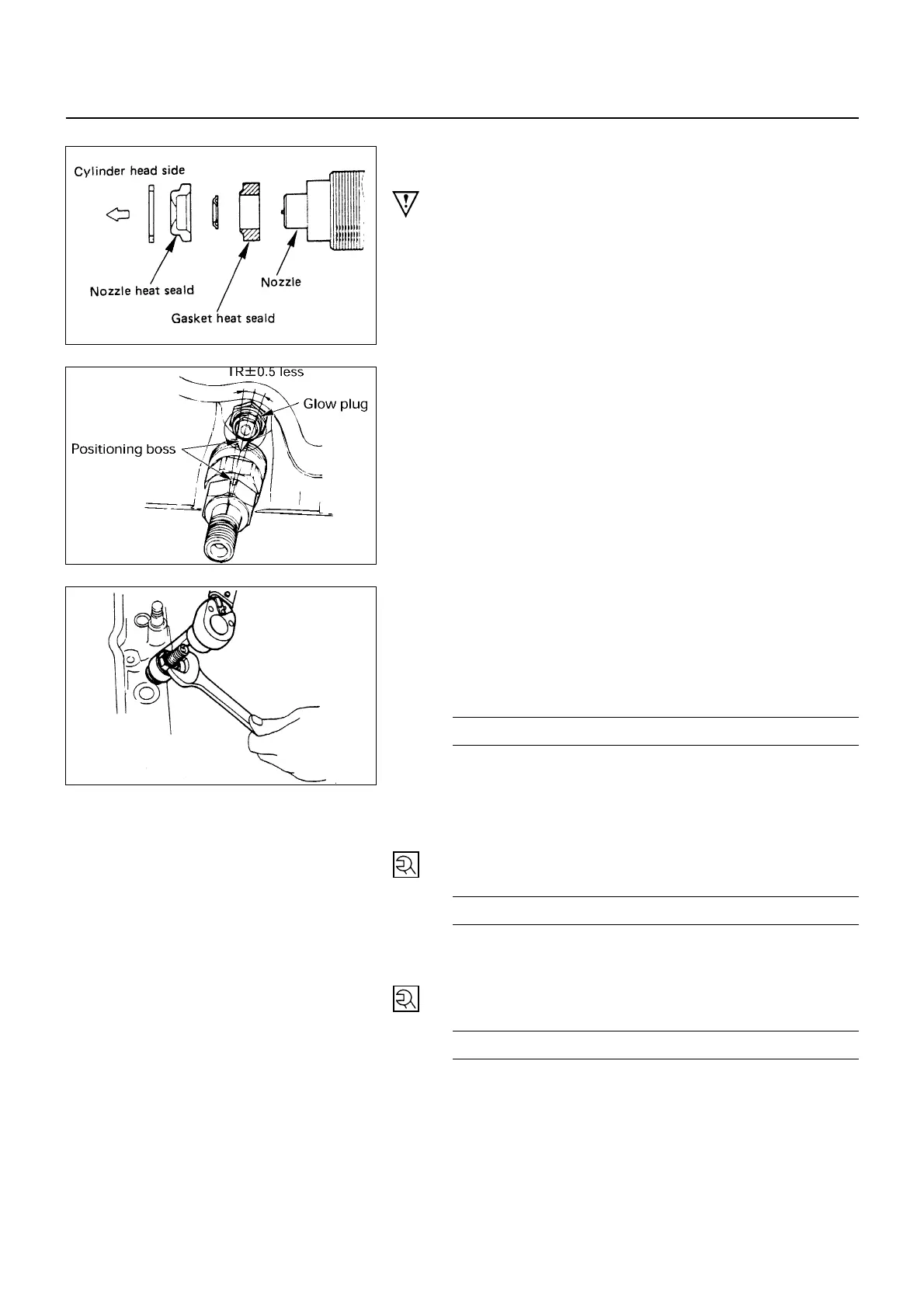

3. Injection Nozzle (4JG2 only)

• Lightly tighten the holder nut to suck extent that the

nozzle holder can turn one word and one word.

• Set positioning confirmation drilled hole (φ2) within a

nozzle turning angle of ±5° against the cylinder head-

side positioning boss.

• Apply a wrench as illustrated and tighten the holder nut

to the specified torque using a special tool.

CAUTION

• After tightening the holder nut, make sure that the

drilled hole makes ±5° or smaller with the cylinder

head-side positioning boss.

• When mounting leak off pipe, injection nozzle and

pipe, clean then with air so that dust may not

enter.

Nozzle Fixing Torque N∙m (Kg∙m/lb∙ft)

64 (6.5/47)

Wrench: nozzle holder 5-8840-0259-0

2. Leak Off Pipe

• Mount using a new copper washer

• Tighten nut to the specified torque.

Pipe Nut Torque N∙m (Kg∙m/lb∙ft)

29 (3.0/22)

1. Injection Pipe

• Connect injection pipe to nozzle holder.

• Tighten the injection pump side.

Sleeve Nut Torque N∙m (Kg∙m/lb∙ft)

29 (3.0/22)

• Fit pipe clip in specified position.

6C-12-1.tif

6C-12-3.tif

040LX016.tif

Loading...

Loading...