7.

After

completing the warm-up operation, check that all

gauges and monitors work properly.

If any problem is found, perform the maintenance or repair.

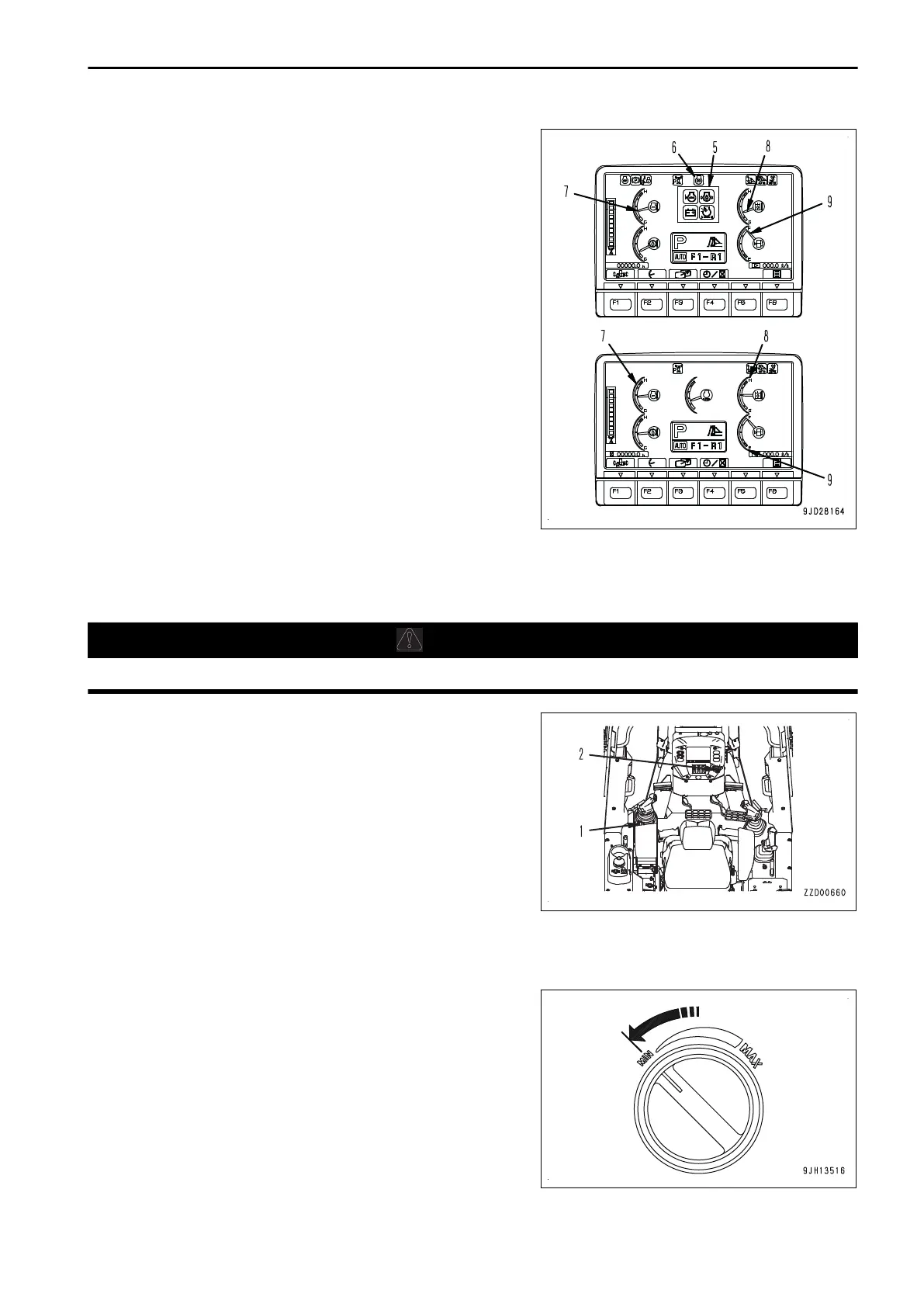

• Caution lamp (5): Is it not lit?

• Engine preheating pilot lamp (6): Is it not lit?

• Engine coolant temperature gauge (7): Is the indicator

in green range?

• Hydraulic oil temperature gauge (8): Is the indicator in

green range

• Fuel gauge (9): Is the indicator in green range?

8.

Check for abnormal exhaust gas color, noise, or vibration.

If any problem is found, contact your Komatsu distributor.

REMARK

If the power train oil temperature is not sufficiently high, it takes longer to reach the maximum speed.

METHOD FOR STOPPING ENGINE

WARNING

Keep away from the exhaust pipe immediately after stopping the engine.

NOTICE

If

the engine is stopped before it is cooled down, the serv-

ice lives of component parts of the engine may be consid-

erably reduced. Do not stop the engine abruptly except in

an emergency.

Do not stop the engine abruptly except the case in an

emergency. If the engine is overheated, do not try to stop it

abruptly but run it at medium speed to allow it to cool

down gradually, and then stop it.

If the engine is stopped during the aftertreatment devices

regeneration, the components may be damaged.

Stop the aftertreatment devices regeneration, and run the

engine at low idle for approximately 5 minutes before stop-

ping the engine. Then stop the engine.

1.

Lower the work equipment to the ground.

2.

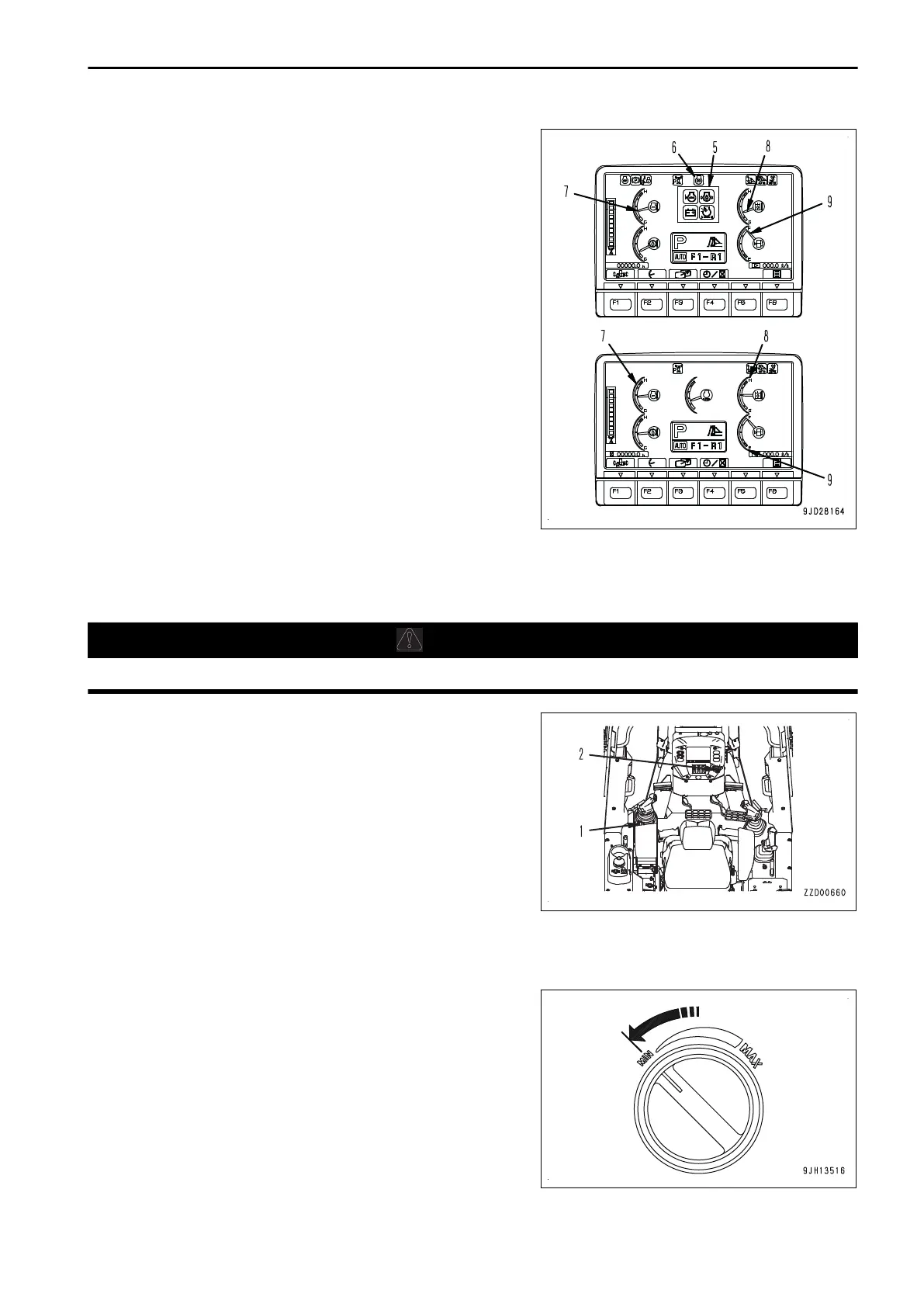

Turn fuel control dial (1) to Low idle (MIN) position.

3.

Run the engine at low idle for approximately 5 minutes to

cool down gradually

.

OPERATION MACHINE OPERATIONS AND CONTROLS

3-169

Loading...

Loading...