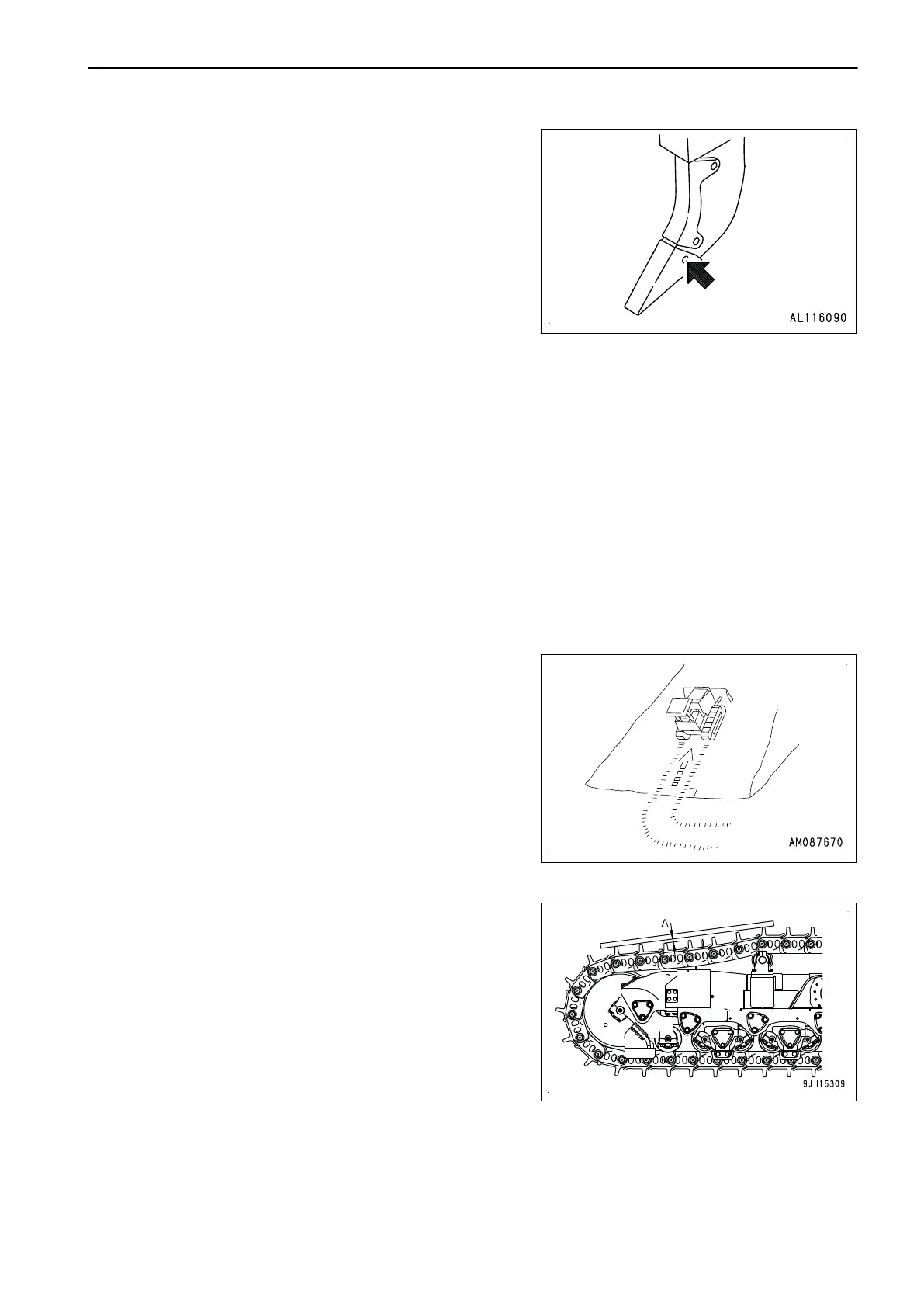

Put a pin puller to the pin indicated by the arrow, and hit it with

a hammer to drive out the pin.

REMARK

Since

the pin is made of one piece, insert the pin half way by

hand, then drive it in with a hammer.

TIPS FOR LONGER UNDERCARRIAGE LIFE

Undercarriage life greatly varies depending on operation method, inspection and maintenance.

For most efficient operation, keep the following points in mind.

OPERATION METHOD

• Use a track shoe suitable for soil condition.

For selection of the shoe, consult your Komatsu distributor.

• Do not let the shoe slip during operation.

If the shoe starts slipping, decrease the load to prevent slipping.

• Avoid rapid start, acceleration, stop, or unnecessary high-speed operation or sharp turn.

• Travel as straight as possible. Do not turn only in either direction but turn in both directions evenly. Also,

secure turning radius as large as possible.

• Clear the travel ground and remove obstacles so that the machine does not ride over large boulders or ob-

stacles.

• On slopes, do not work across the slope surface but work

upward or downward. When stopping the machine on a

slope, direct it up or down.

• If the ground slants to the right or left while the machine is

digging, do not stay there but move back to a level place,

then start digging again.

• If the idler or sprocket floats because of a hard obstacle

during dozing or ripping work, avoid that obstacle, since it

is “difficult to move it”.

METHOD FOR CHECKING AND ADJUSTING

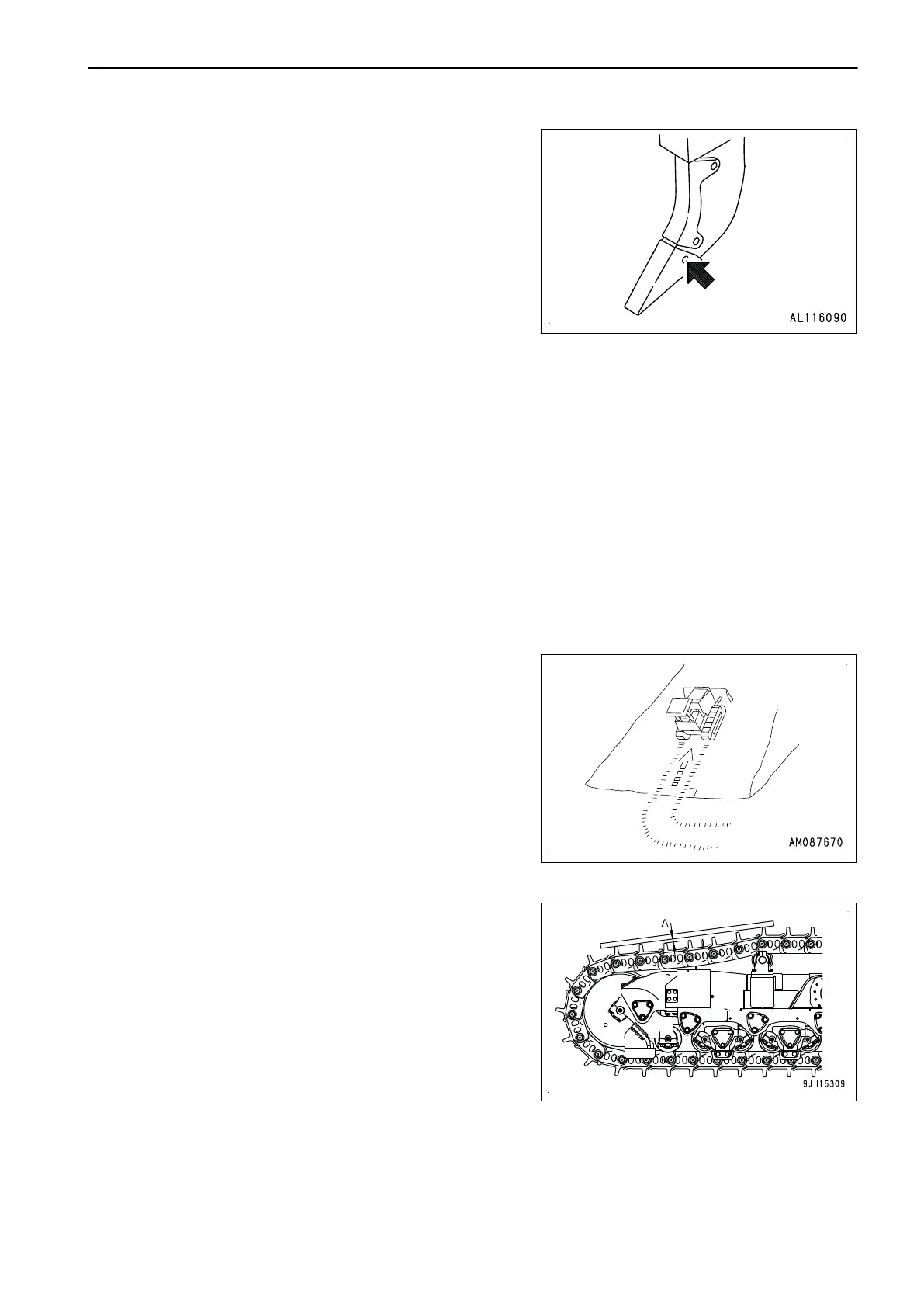

• Adjust the track tension to a proper level.

Check the tension by measuring clearance (A) shown in

the

figure. This clearance should be 20 to 30 mm usually.

However, tense a little higher for rocky terrain and a little

lower for clay land.

For an inspection and maintenance method, see “METH-

OD FOR CHECKING AND ADJUSTING TRACK TEN-

SION”, and perform an inspection and adjustment of track

tension.

• Check the idler and rollers for oil leakage and loose bolts

and nuts.

Repair abnormality immediately, if any.

METHOD FOR CHECKING AND REPAIRING

Frequent inspection and prompt repair will reduce repair costs.

OPERATION MACHINE OPERATIONS AND CONTROLS

3-205

Loading...

Loading...